Method for calculating oxygen diffusion coefficient of polydimethylsiloxane

A polydimethylsiloxane and diffusion coefficient technology, applied in the field of polymer design and synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

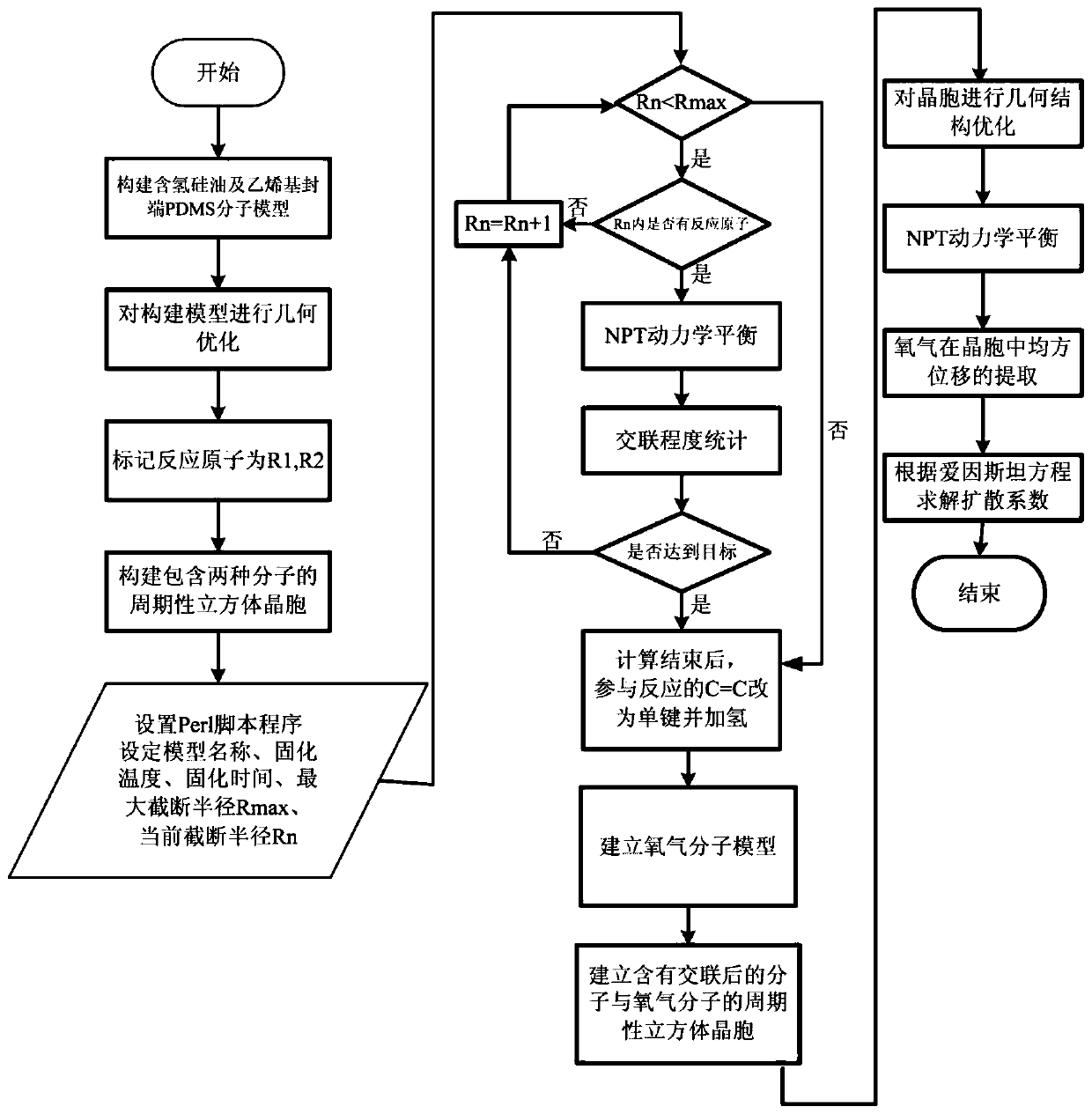

Method used

Image

Examples

Embodiment

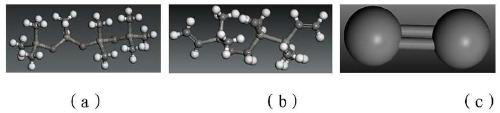

[0039] Vinyl terminated PDMS prepolymer CH 2 =CH-Si(CH 3 ) 2 -[OSi(CH 3 ) 2 ] n O-Si(CH 3 ) 2 -CH=CH 2 And hydrogen-containing silicone oil crosslinking agent (CH 3 ) 3 SiO-[Si(CH 3 ) 2 O] X -[OSiHCH 3 ] Y O-Si(CH 3 ) 3 For example, in order to simplify the calculation speed of the model, the above-mentioned molecules are simplified as follows, let n=1, X=0, Y=1, and the built model is as follows figure 2 shown.

[0040] The specific implementation process is as follows:

[0041] Step 1: Building a Molecular Model

[0042] According to the actual molecular structure formula, the part of the model that does not participate in the reaction is simplified to obtain the following figure 2 The molecular model shown, where figure 2 (a) is the molecular model of hydrogen-containing silicone oil crosslinking agent, figure 2 (b) is the molecular model of vinyl-terminated PDMS prepolymer, figure 2 (c) is the oxygen molecule model.

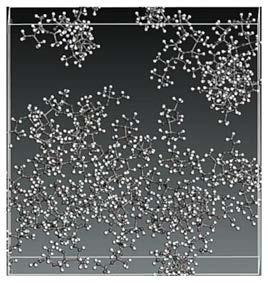

[0043] Step 2: By using the C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com