Patents

Literature

35 results about "Oxygen diffusion coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

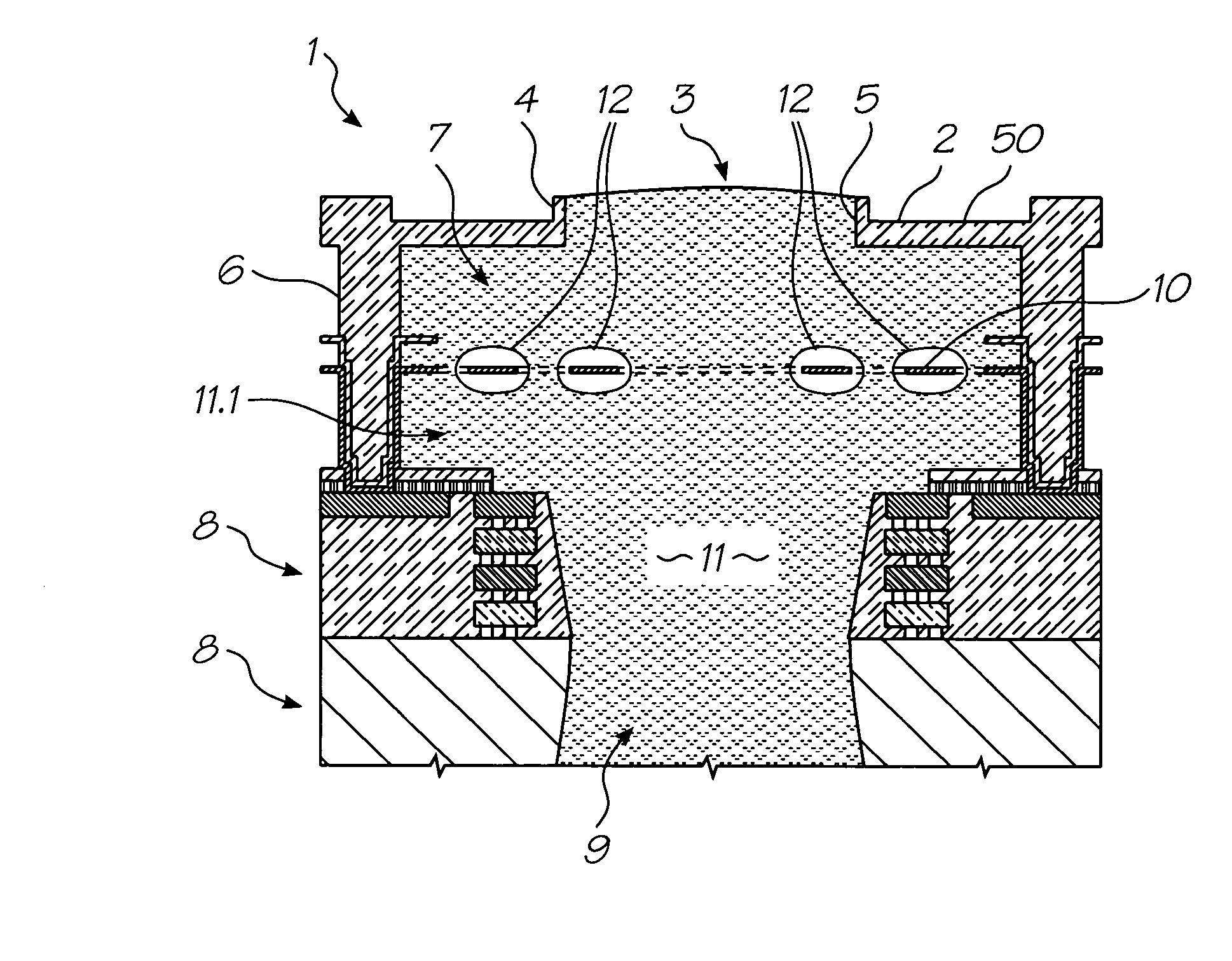

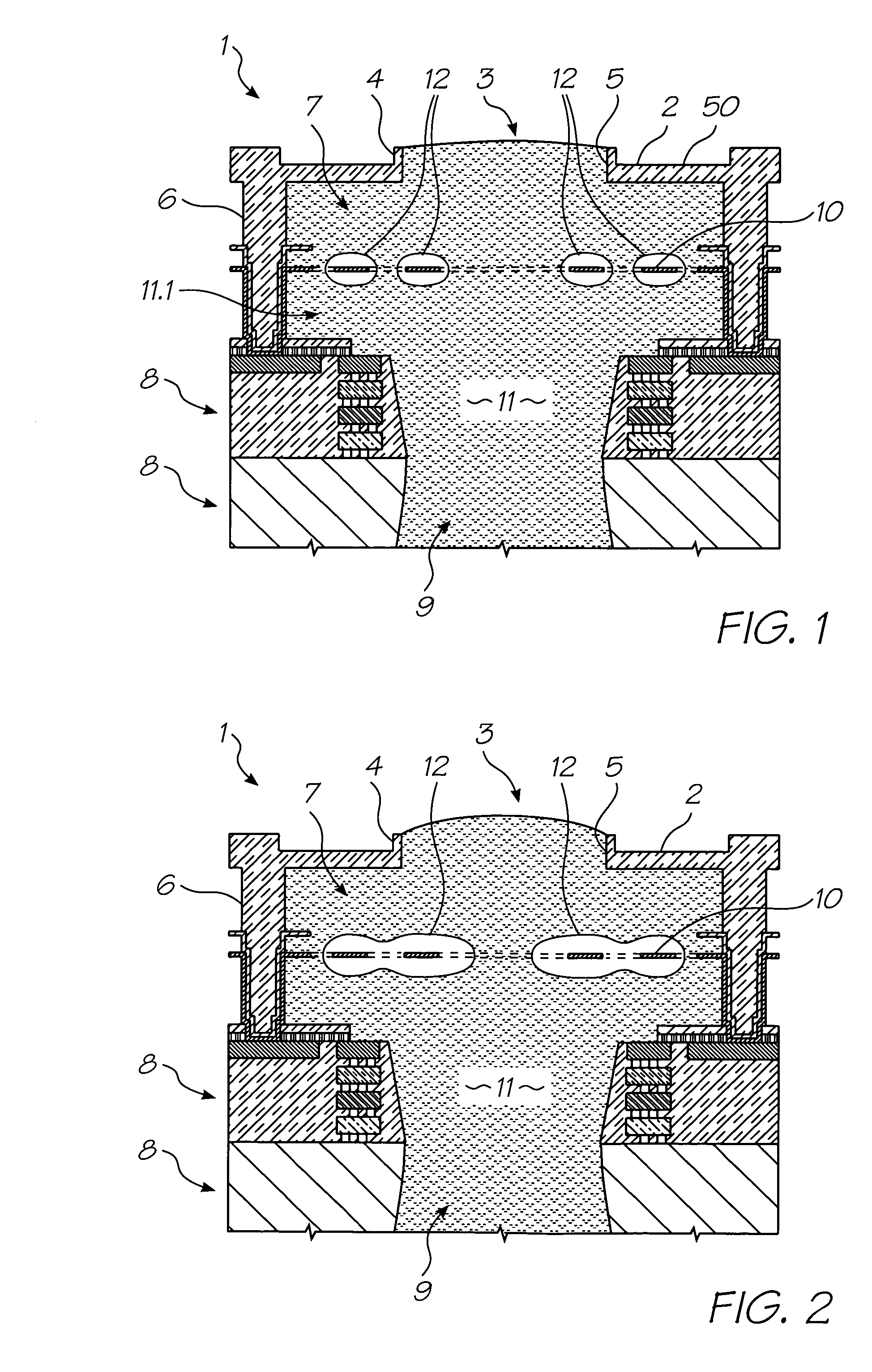

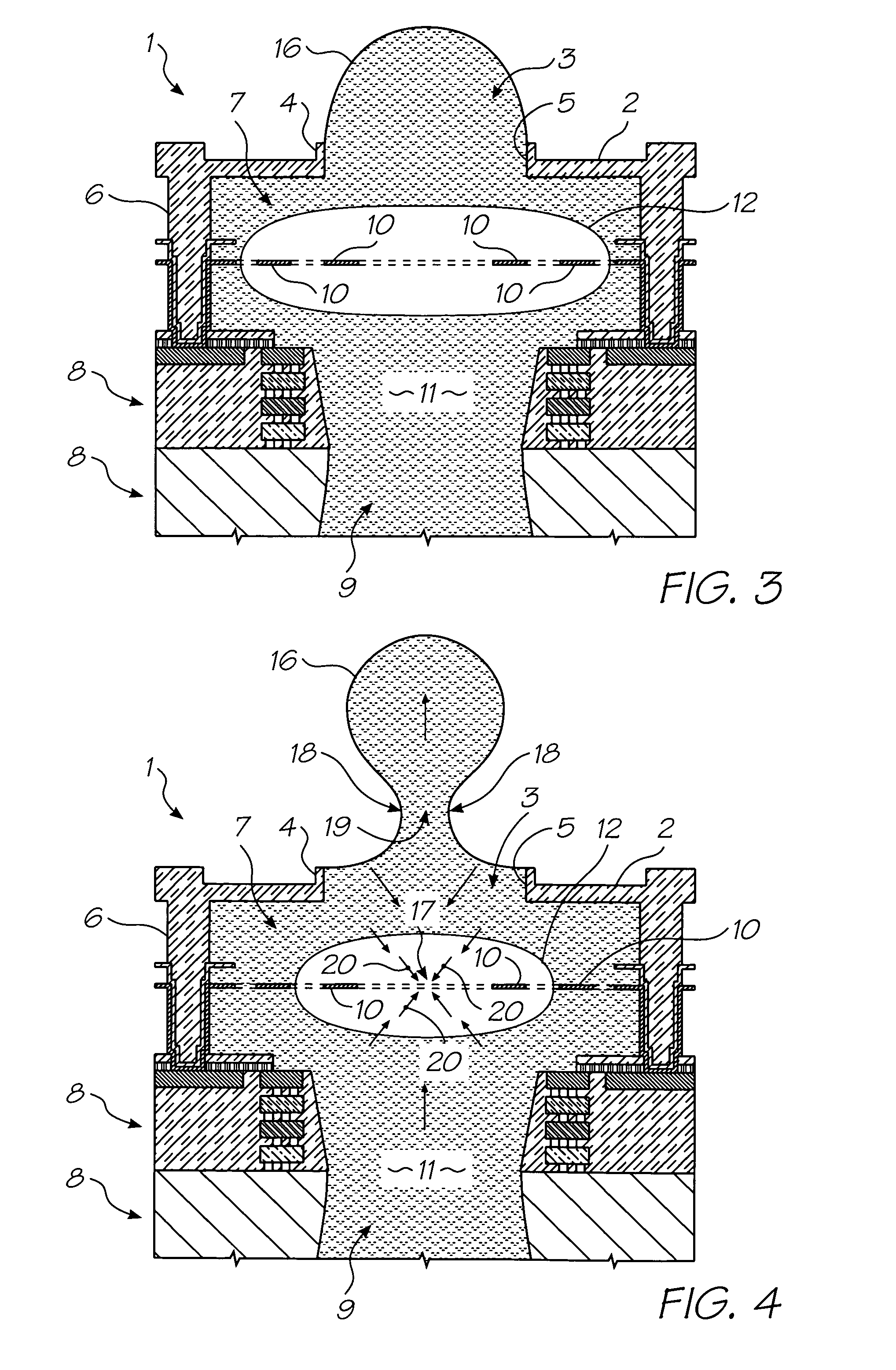

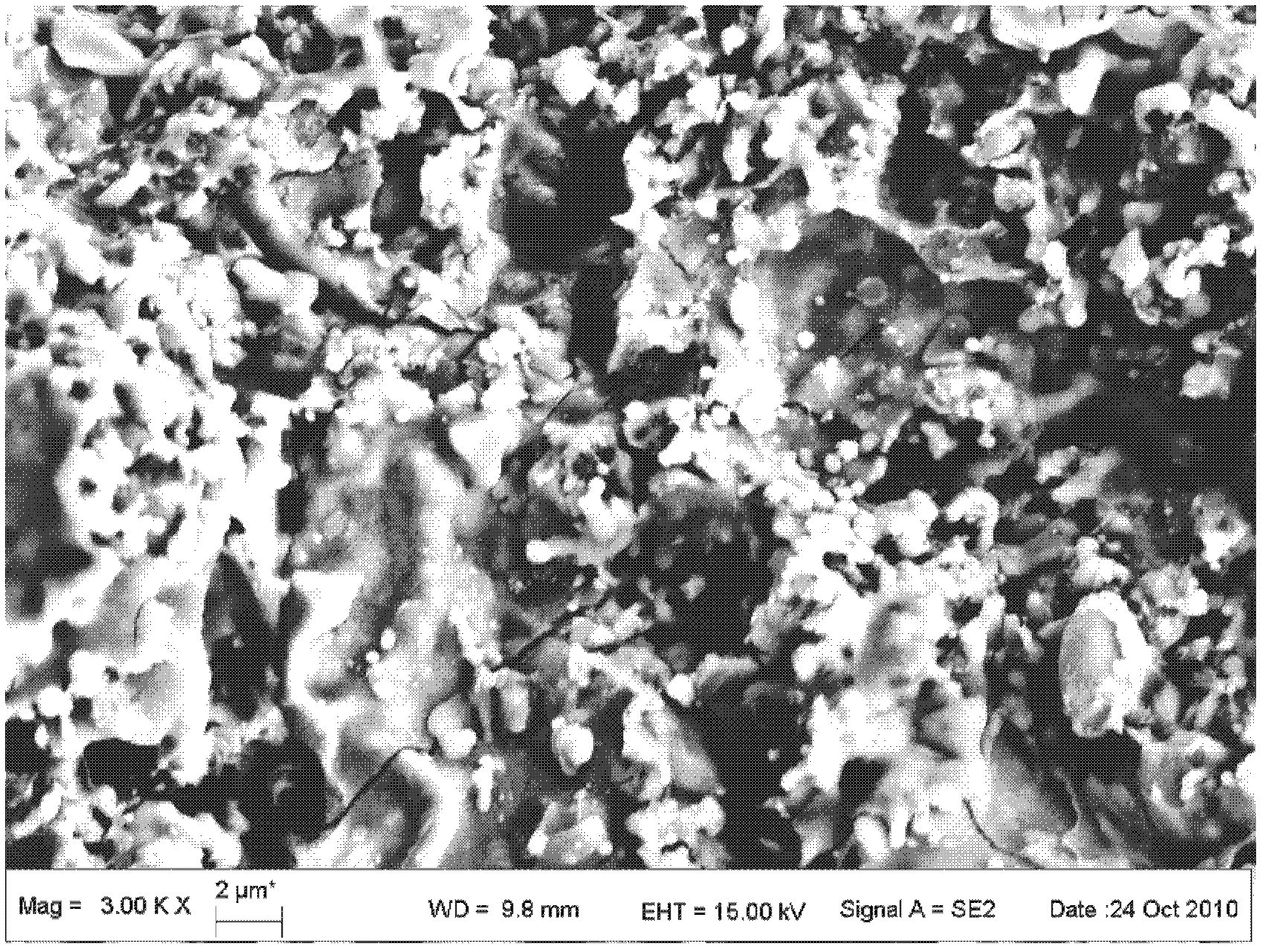

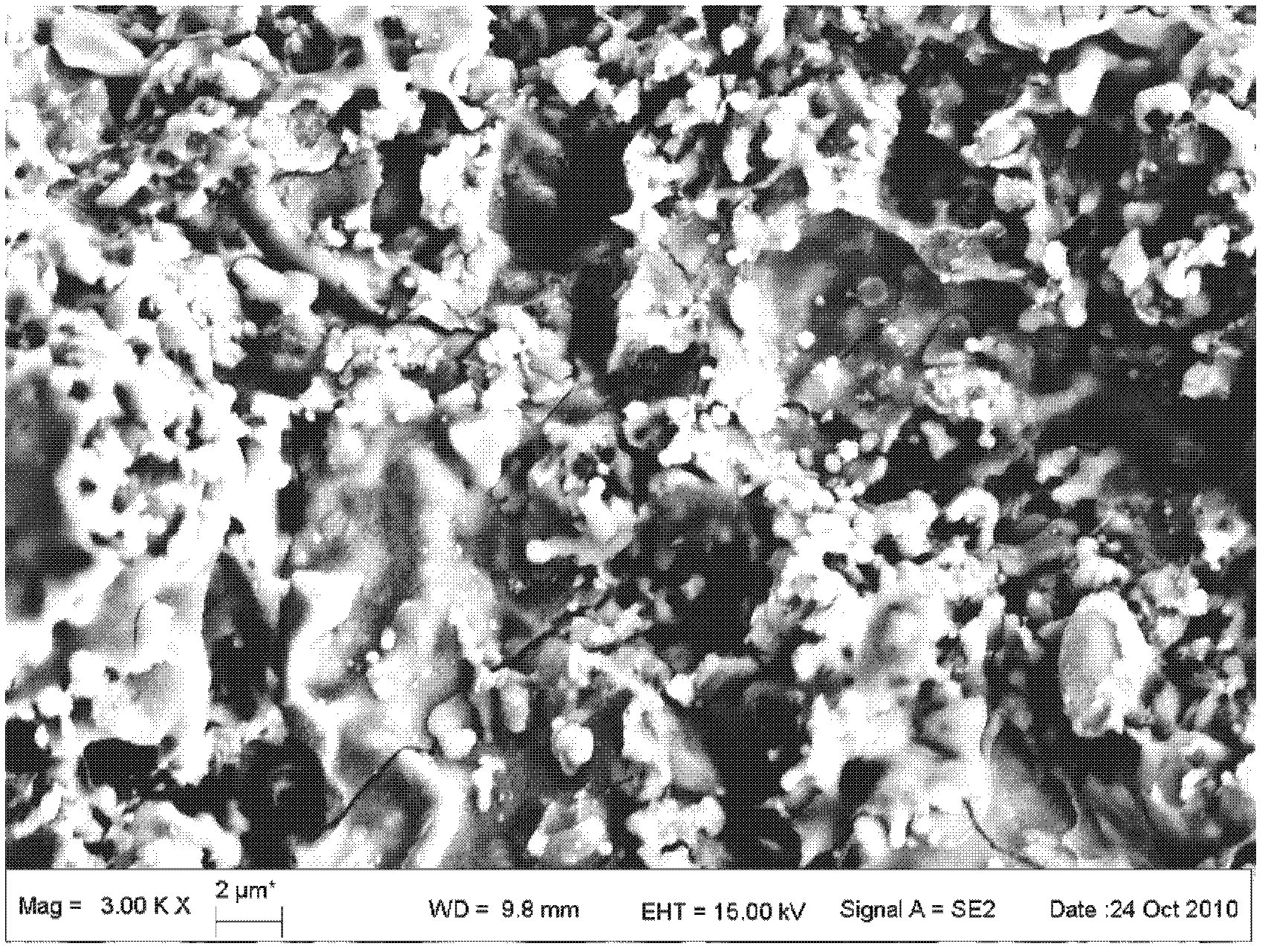

Self passivating transition metal nitride printhead heaters

InactiveUS7431431B2Improve antioxidant capacityLower energy requirementsInking apparatusOther printing apparatusOxygenNitride

A thermal inkjet printhead with heater elements formed from a self passivating transition metal nitride, but it oxidizes readily. By introducing an additive that allows the metal nitride to self passivate, the heater element forms a surface oxide layer, where the oxide has a low diffusion coefficient for oxygen so as to provide a barrier to further oxidation. With enhanced oxidation resistance, coatings to protect the heater from oxidative failure become unnecessary and the energy needed to form a bubble is reduced.

Owner:MEMJET TECH LTD +1

Carbon/carbon composite material ultrahigh temperature oxidation resistant coating and preparation method thereof

The invention discloses a carbon / carbon composite material ultrahigh temperature oxidation resistant coating. The coating comprises the following components, by volume, 40-60% of ZrB2, 15-25% of SiC, 15-20% of TaB2 and 10-15% of Sc2O3. In addition, the invention also provides a preparation method of the coating. According to the invention, TaB2 and Sc2O3 are added to make the melting point of an external layer oxidation product borosilicate glass be risen, the viscosity of the borosilicate glass be risen, the evaporation rate of the borosilicate glass be reduced, the oxygen dispersion coefficient of the borosilicate glass be reduced, an internal layer oxidation product ZrO2 phase be stable, the melting point of ZrO2 be risen, and the oxygen diffusion coefficient of ZrO2 be reduced, so thecoating can satisfy requirements of the ultrahigh temperature oxidation resistance of a carbon / carbon composite material, the coating can be sintered without applying a pressure through adding TaB2 and Sc2O3, the coating has the advantages of high combination strength, compactness, and good ultrahigh temperature mechanical property, and the preparation process has no damages to matrixes.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

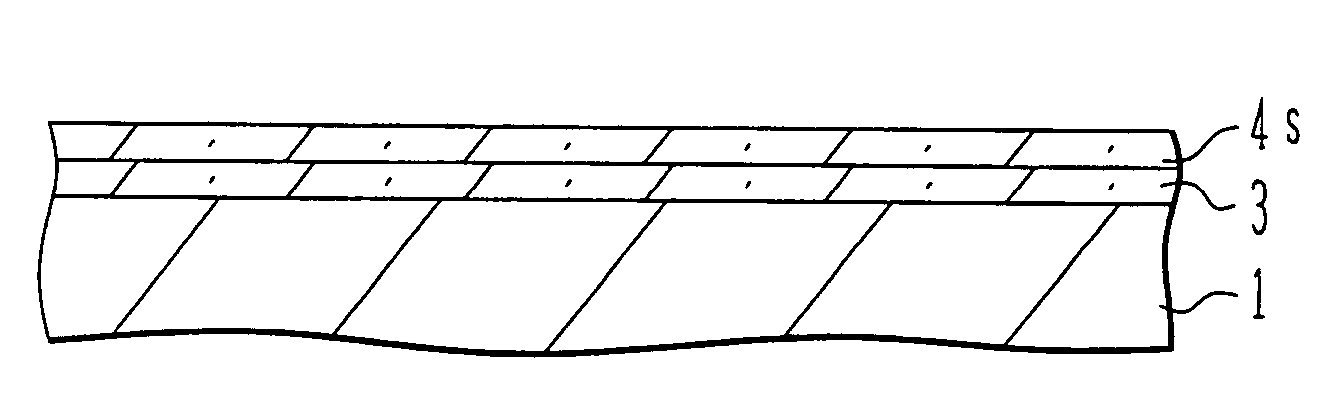

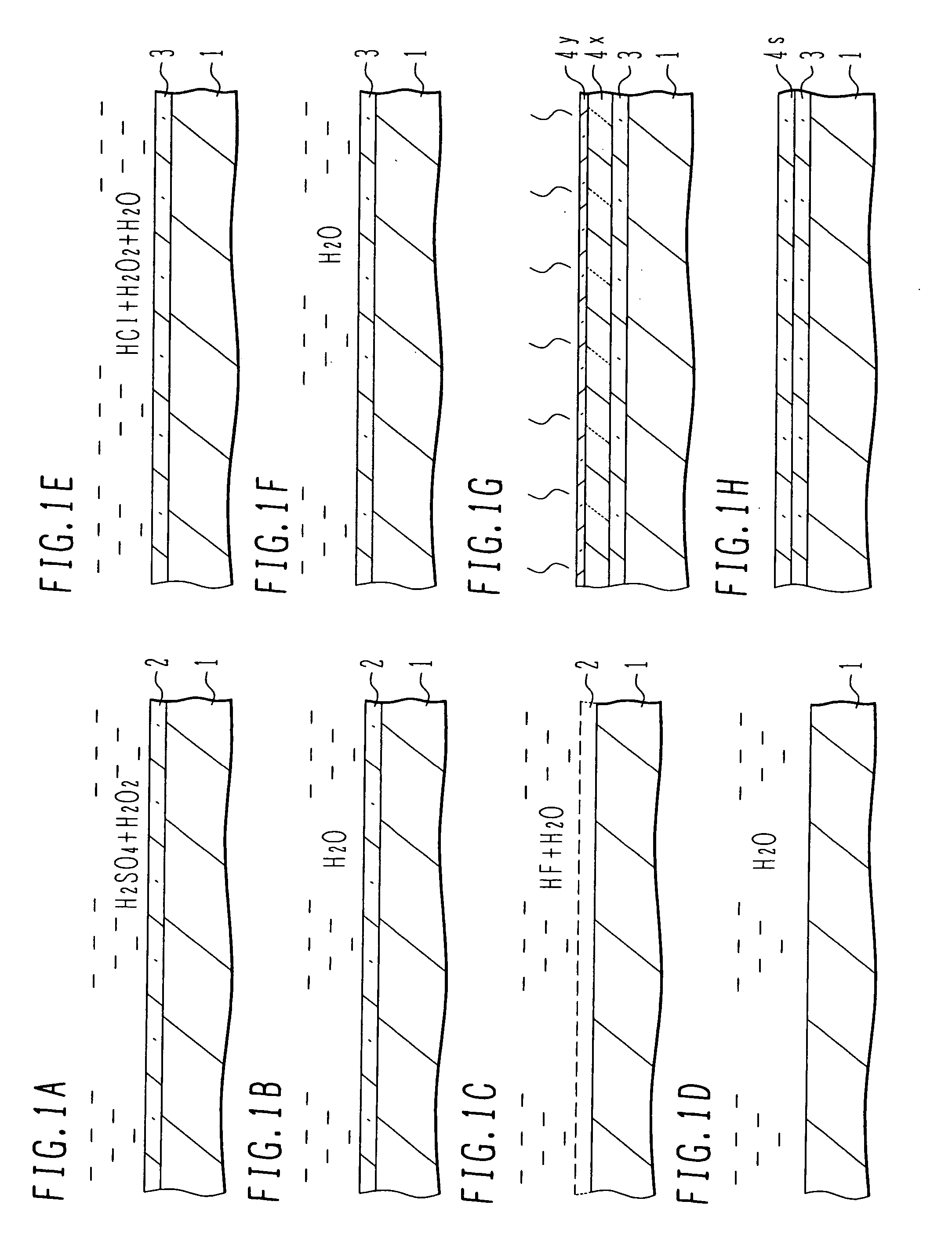

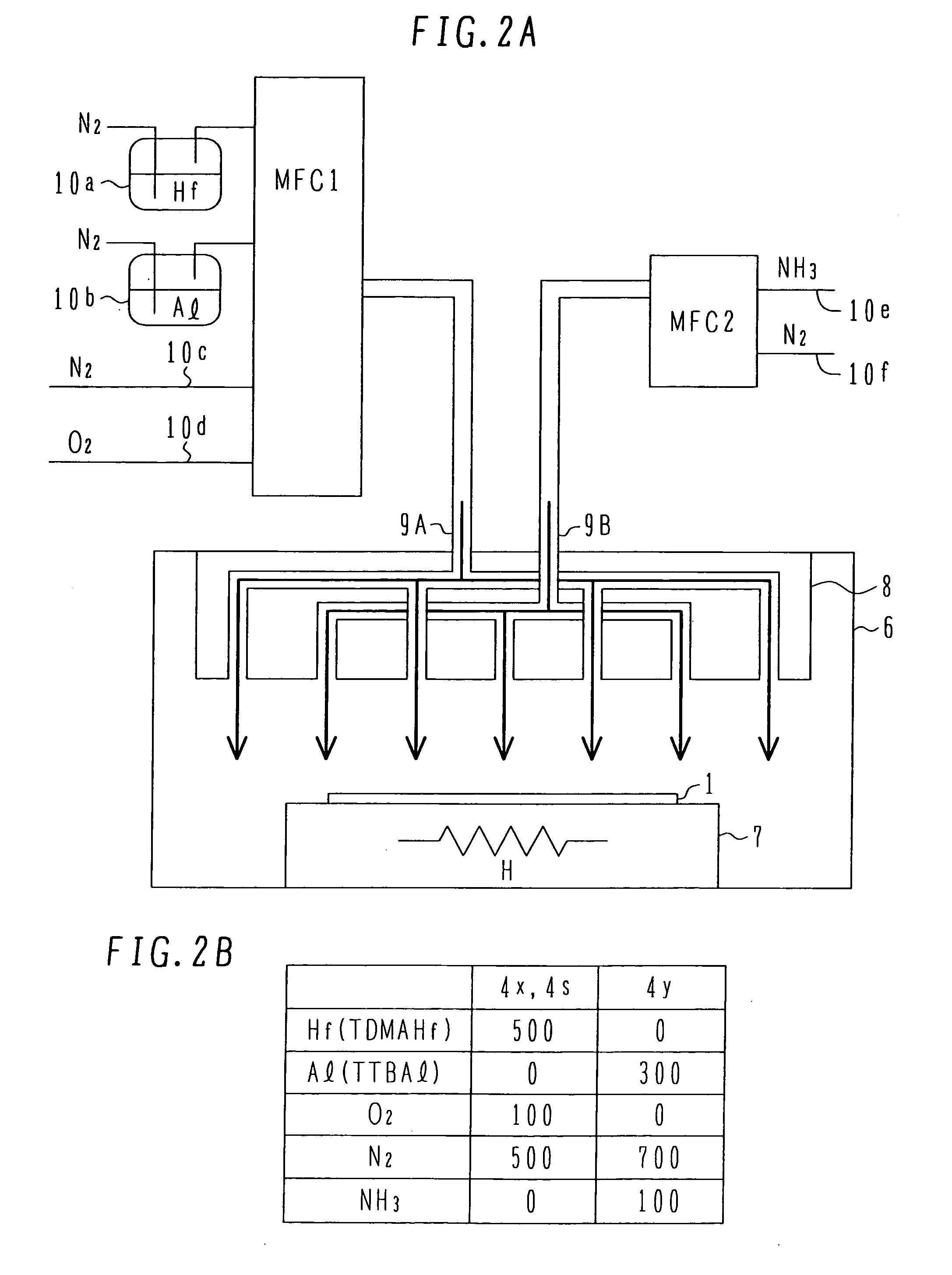

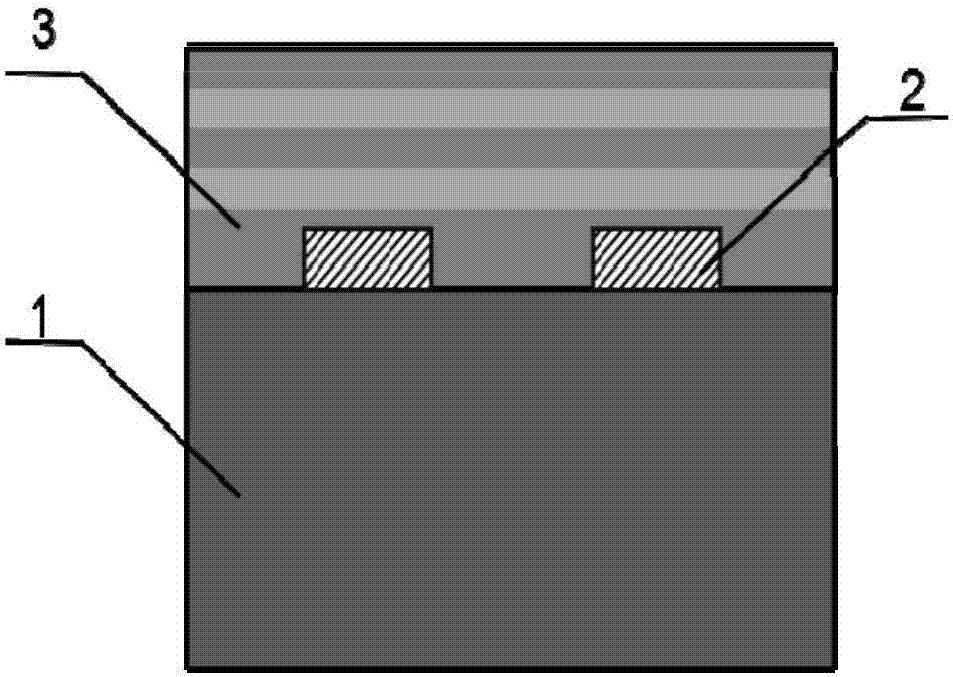

Semiconductor device with high dielectric constant insulator and its manufacture

InactiveUS20050142715A1Reduce hysteresisShift in flat band voltageSemiconductor/solid-state device manufacturingChemical vapor deposition coatingSilicon oxideNitride

A semiconductor device has: a silicon substrate; a silicon oxide layer formed on the surface of the silicon substrate; a high dielectric constant insulating film including a first oxide layer formed above the silicon oxide layer and made of a high dielectric constant film having a dielectric constant higher than silicon oxide and a first nitride layer formed above the first oxide layer and made of nitride having an oxygen intercepting capability, or a high dielectric constant insulating film including a first oxide film formed on the silicon oxide layer, a second oxide layer formed on the first oxide layer and a third oxide layer formed on the second oxide layer, the first and third oxide layers having an oxygen diffusion coefficient smaller than the second oxide layer; and a gate electrode formed on the high dielectric constant insulating layer and made of oxidizable material.

Owner:FUJITSU MICROELECTRONICS LTD

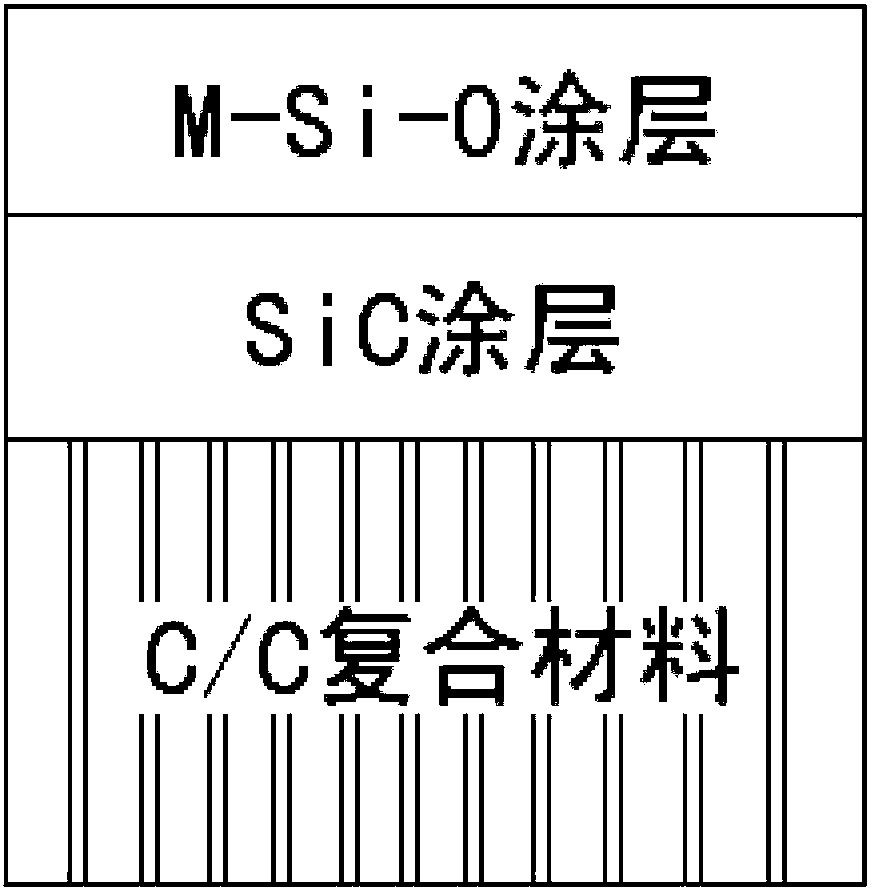

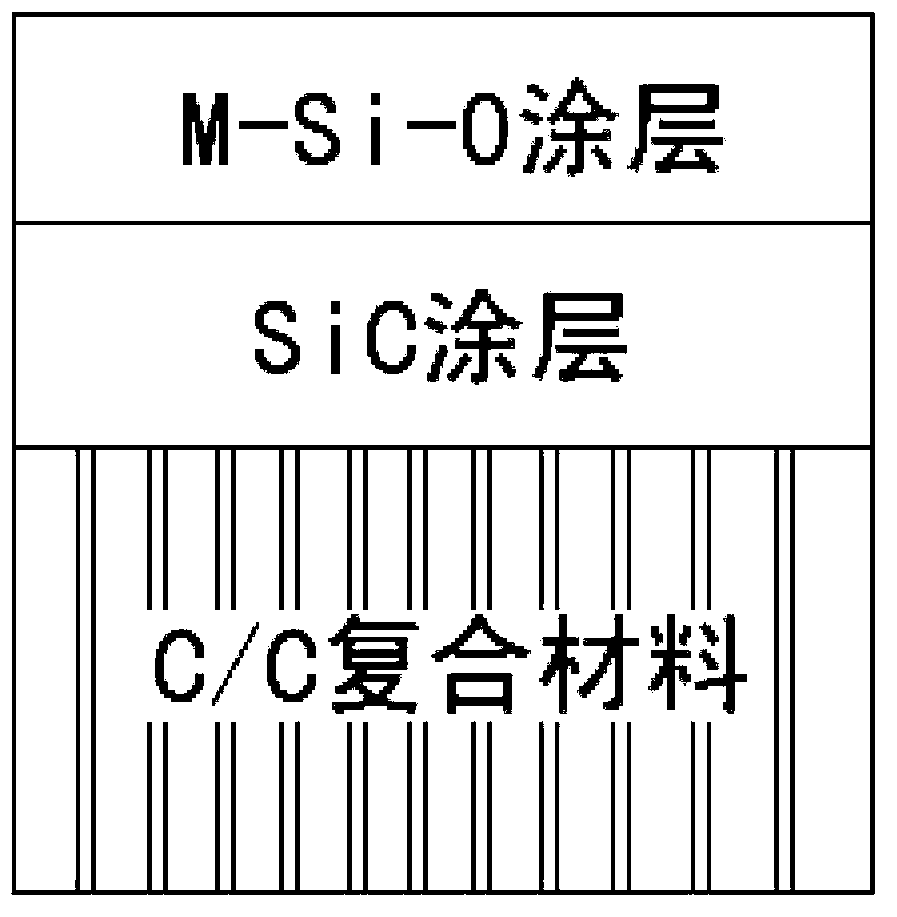

Composite coating and application thereof in carbon/carbon composite material

The invention relates to a composite coating and application thereof in a carbon / carbon composite material, and belongs to the technical field of manufacturing of an anti-oxidizing carbon / carbon composite material. An SiC coating which is similar to a coefficient of thermal expansion of the carbon / carbon composite material is adopted as a base transition layer; the SiC coating is prepared by adopting an in situ chemical reaction method; gradient transition of Si-C is achieved on carbon / carbon composite material matrix; the binding strength of the carbon / carbon matrix and the SiC coating is enhanced; the difference of thermal expansion between the carbon / carbon matrix and an M-Si-O coating is effectively relieved; the M-Si-O coating with high temperature resistance grade, low oxygen diffusion coefficient and high thermal emissivity is selected as an outer coating; the M-Si-O coating is prepared by sol dipping-high temperature sintering treatment.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

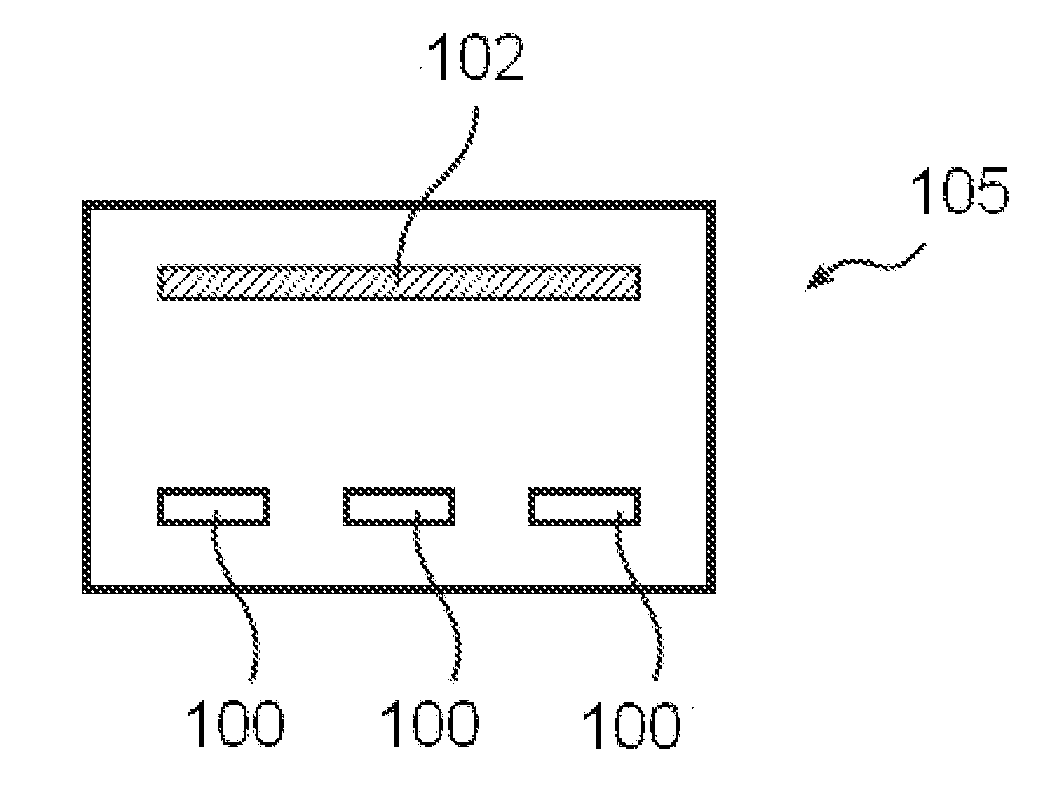

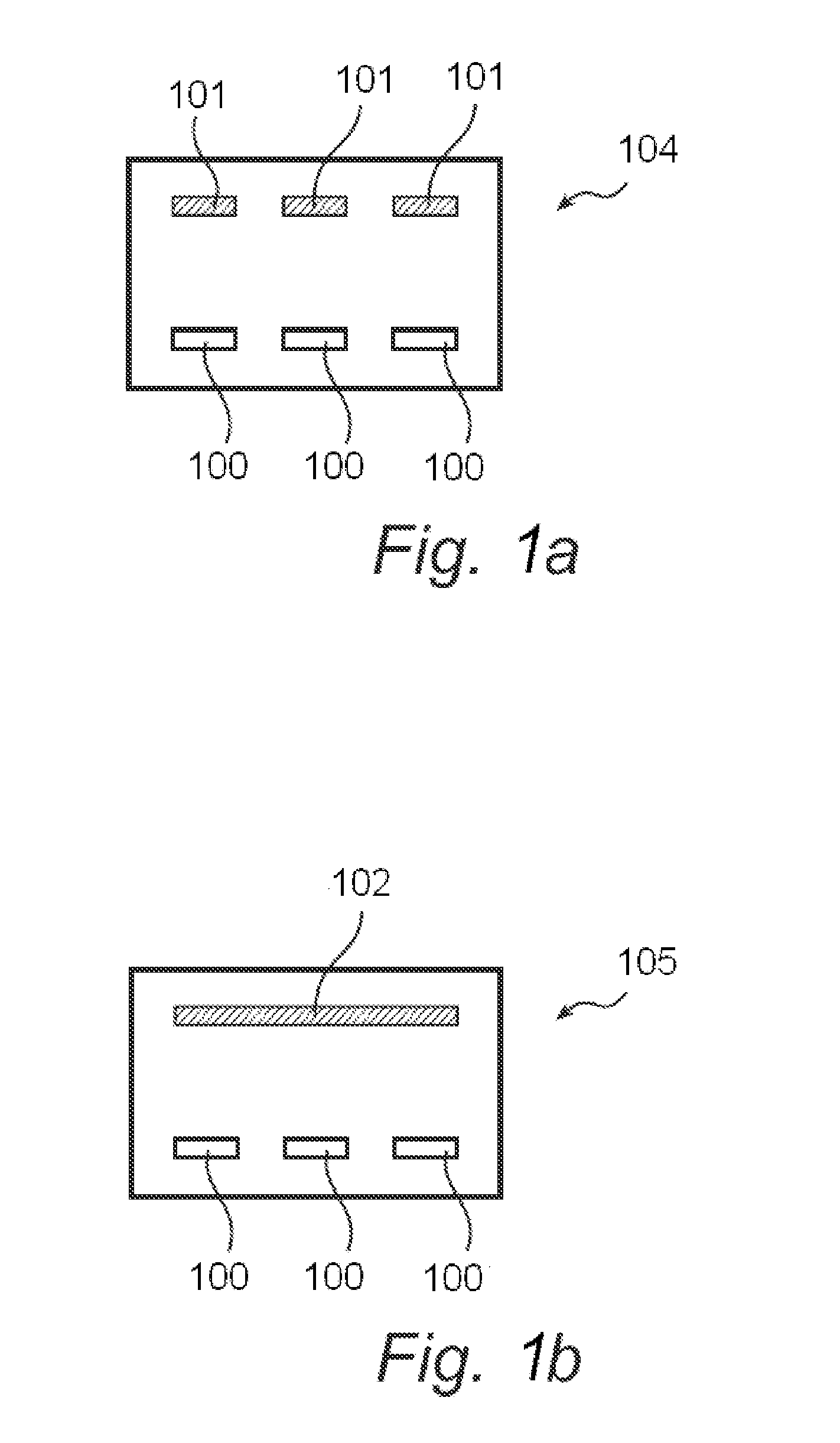

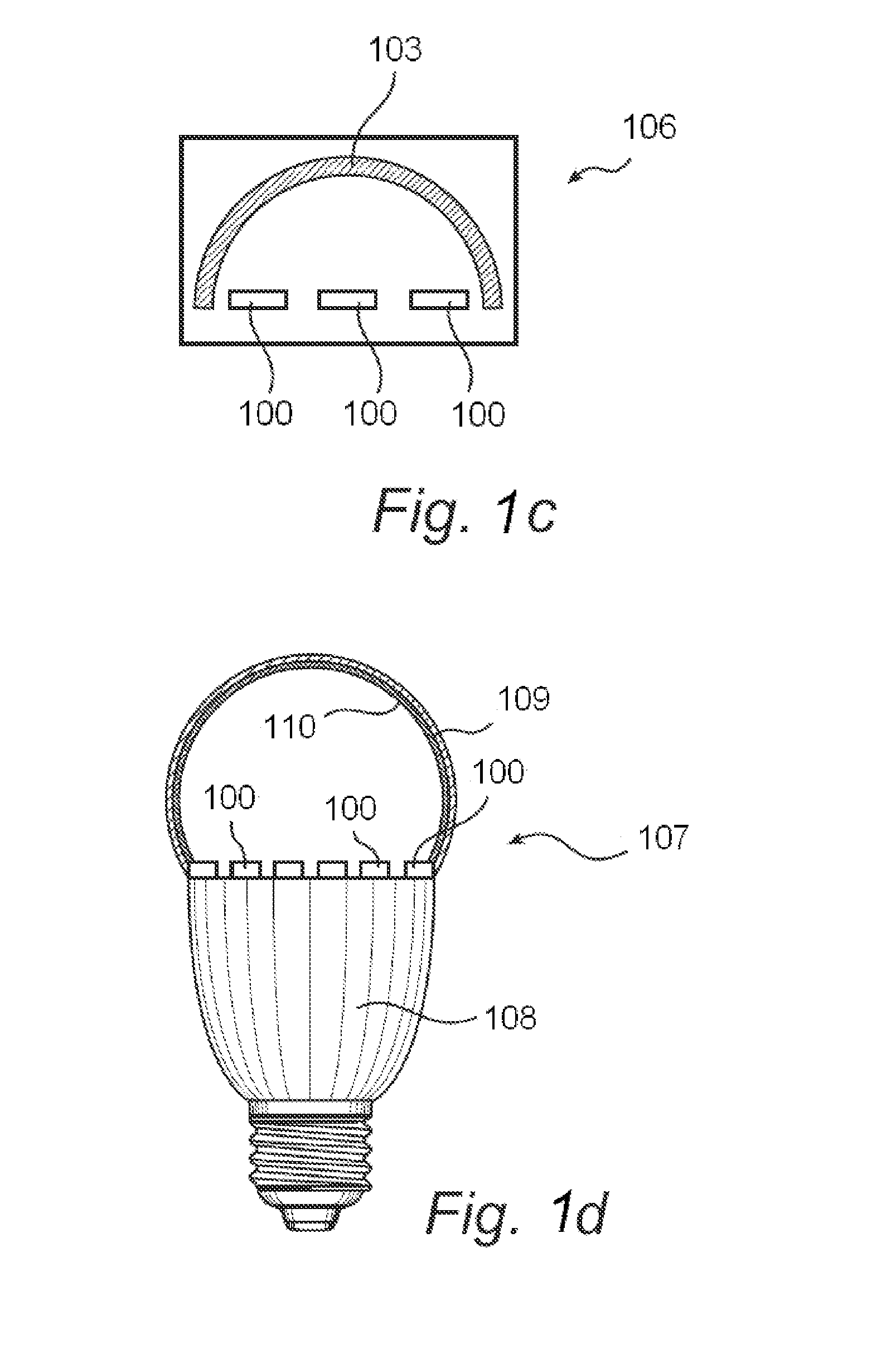

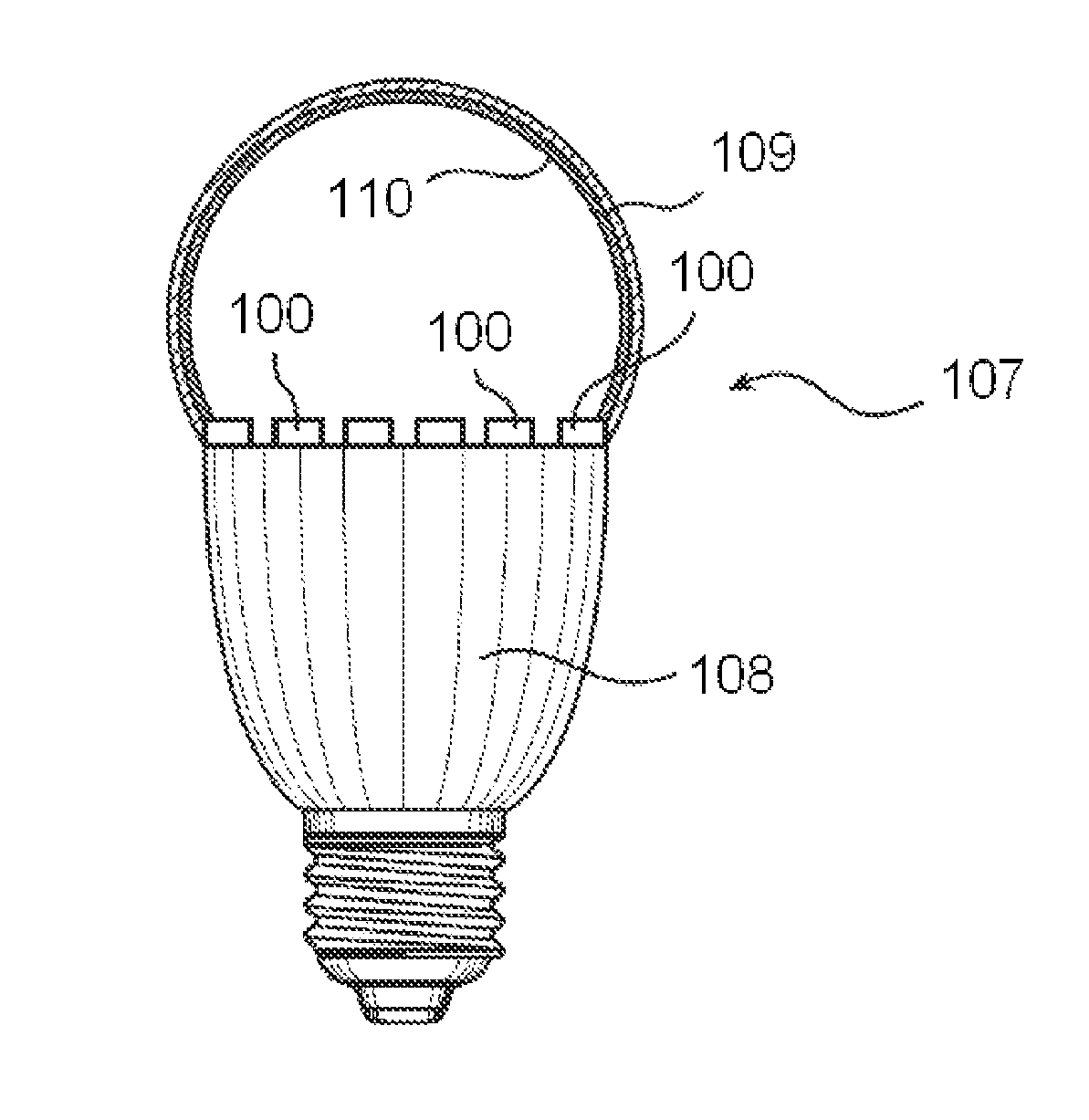

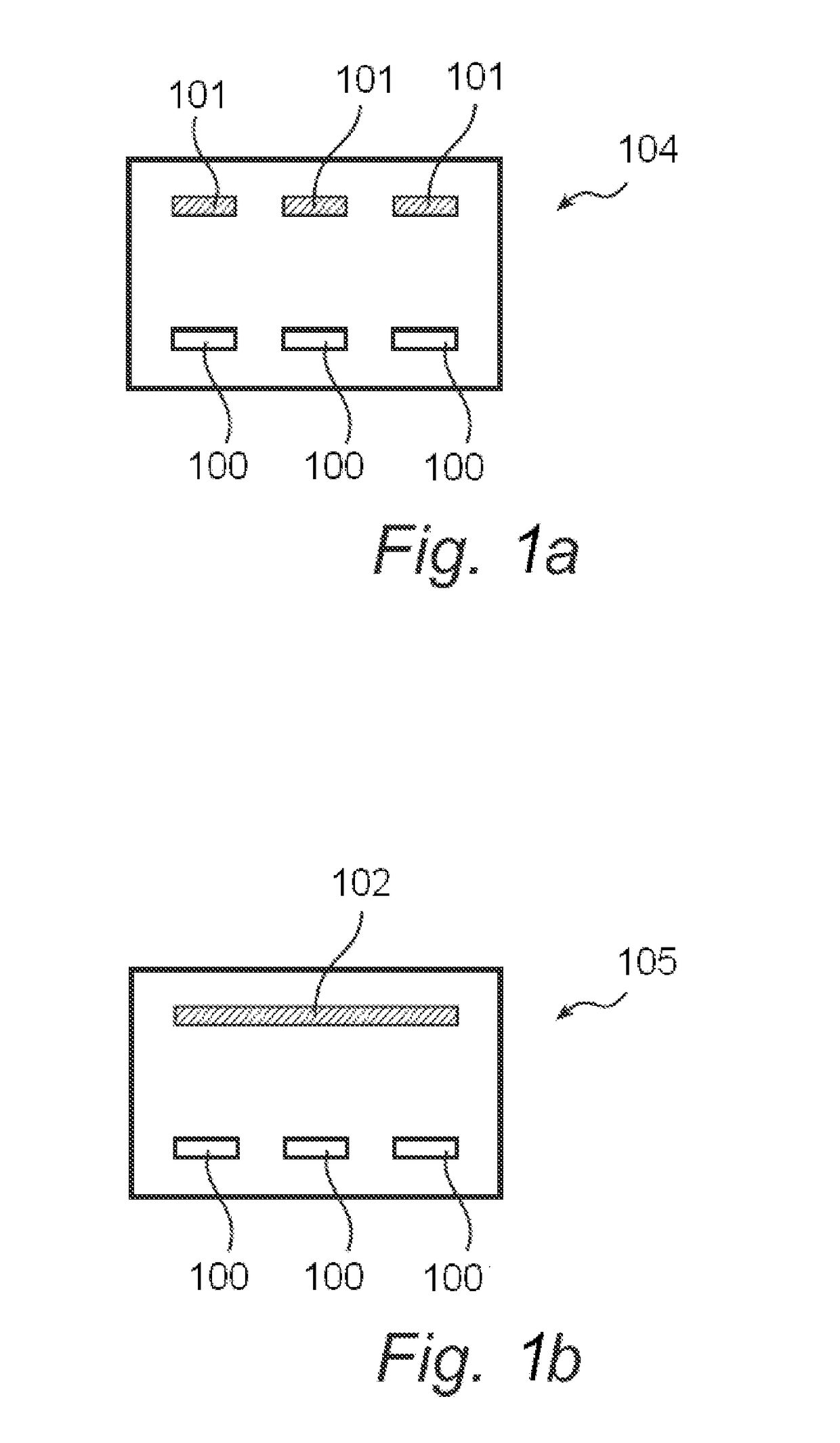

Wavelength converting element

ActiveUS20140125222A1Extended service lifeIncrease oxygen concentrationDischarge tube luminescnet screensElectroluminescent light sourcesLength waveWavelength conversion

A wavelength converting element (101, 102, 103, 110) comprising a polymeric carrier material comprising a first wavelength converting material adapted to convert light of a first wavelength to light of a second wavelength, wherein the oxygen diffusion coefficient (D) of the polymeric carrier material is 8×10−13 cm2 / s or less at 25° C. A prolonged lifetime of the wavelength converting material is achieved by selecting a polymeric carrier material with an oxygen diffusion coefficient (D) at 8×10−13 cm2 / s or less at 25° C.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

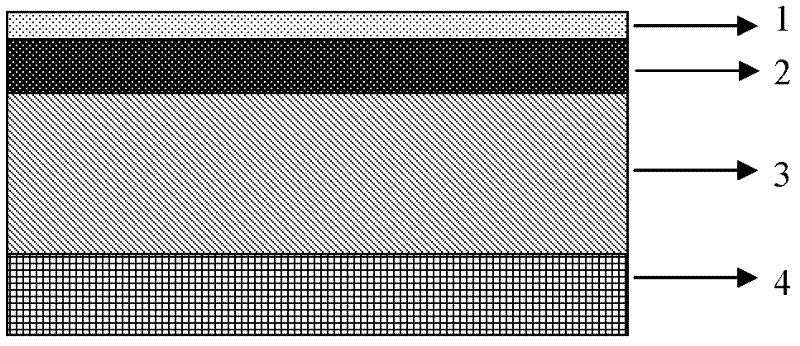

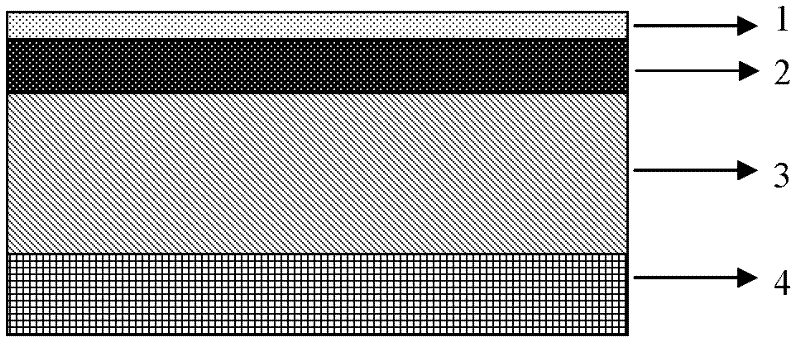

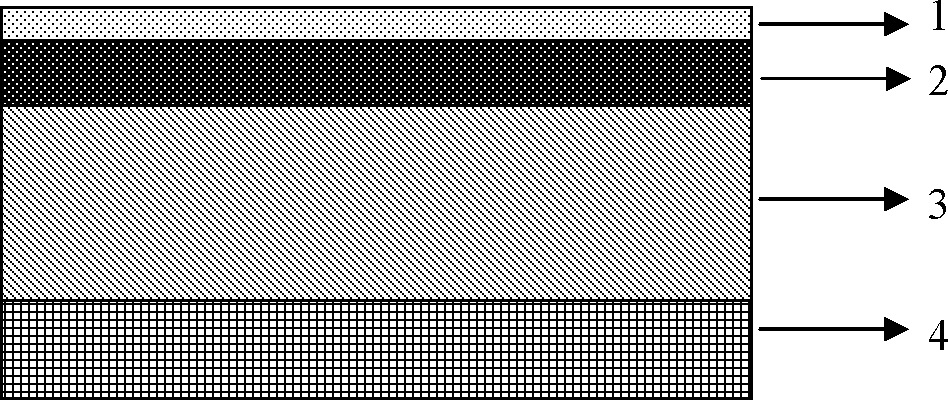

High-temperature thin film sensor with self-healing composite protective layer and preparation method thereof

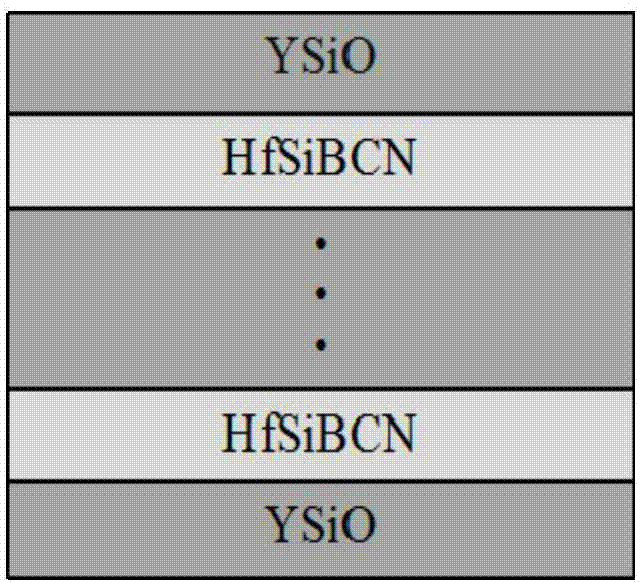

InactiveCN107201502AImprove antioxidant capacityExtended service lifeEngine testingVacuum evaporation coatingSelf-healingMultilayer membrane

The invention belongs to the technical field of a sensor, and provides a high-temperature thin film sensor with a self-healing composite protective layer and a preparation method thereof, and aims to realize miniaturization and thin-film application of the sensor. The thin film sensor is composed of a substrate, a thin film sensor sensitive functional layer and the self-healing composite protective layer, which are arranged from bottom to top in order, wherein the structure of the self-healing composite protective layer comprises YSiO / HfSiBCN periodic multilayer membrane structures from bottom to top in order, and the lowest layer and the topmost layer of the protective layer are both YSiO low-oxygen diffusion coefficient layers. The high-temperature thin film sensor adopts the self-healing composite protective layer with the self-healing composite protective layer, the YSiO low-oxygen diffusion coefficient layers and HfSiBCN self-healing layers are alternately deposited to form an anti-oxidative protection system with layers of protection, and therefore the thin film sensor can work for a long time under the condition of high temperature of 600-1500DEG C and has the advantages of high temperature resistance, corrosion resistance, oxidation resistance, fast response, etc.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Wavelength converting element

ActiveUS9897285B2Extended service lifeIncrease oxygen concentrationElectroluminescent light sourcesLuminescent compositionsLength waveOxygen

Owner:KONINK PHILIPS ELECTRONICS NV

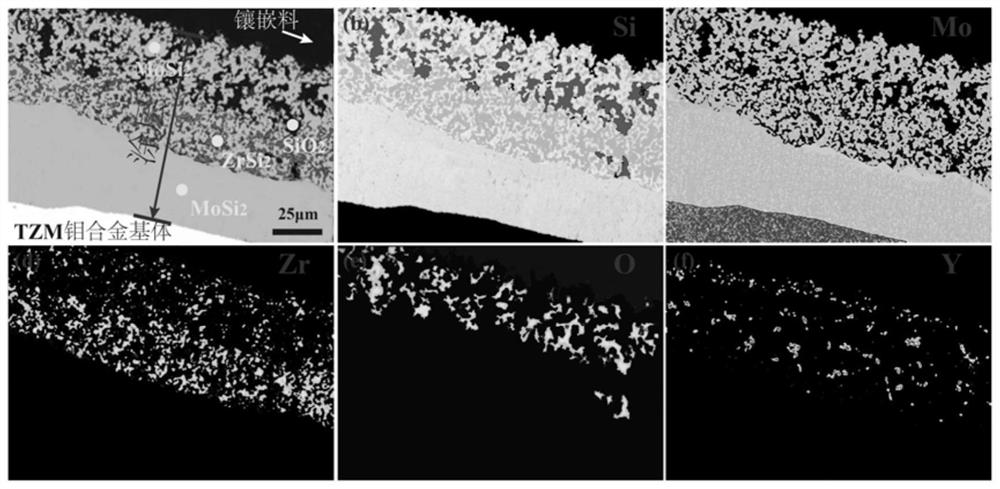

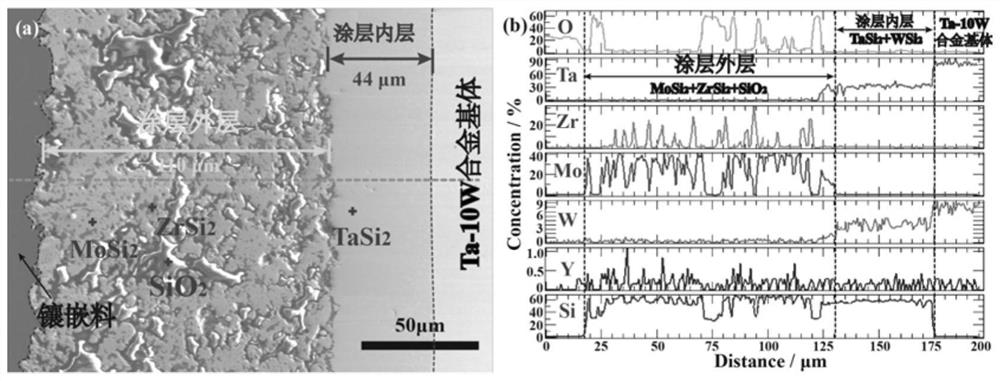

Refractory metal high-temperature antioxidant Si-Mo-YSZ coating and preparation method thereof

The invention relates to a refractory metal high-temperature antioxidant Si-Mo-YSZ coating and a preparation method thereof. The refractory metal high-temperature antioxidant Si-Mo-YSZ coating is madefrom, by weight, 45-65% of Si, 25-40% of Mo, 2-15% of YSZ (yttria-stabilized zirconia), and 2-8% of additives. Materials of coating are made into a slurry first; the slurry is applied to the surfaceof a refractory metal; the refractory metal is sintered at 1370-1530 DEG C for 20-90 min. since the coating composition is reasonably made in conjunction with thermal expansion coefficient of a refractory metal base, the coating, during use, can quickly form a ZrSiO4-ZrO2-SiO2 composite oxide film, effectively reducing oxygen diffusion coefficient of the coating, and implementing long-term antioxidant use of various refractory metals at the temperature of 1700 DEG C and above. The preparation method is simple and low in cost; the coating has good thermal matching with a base; high-temperatureoxidation resistance of refractory metals can be effectively improved.

Owner:CENT SOUTH UNIV

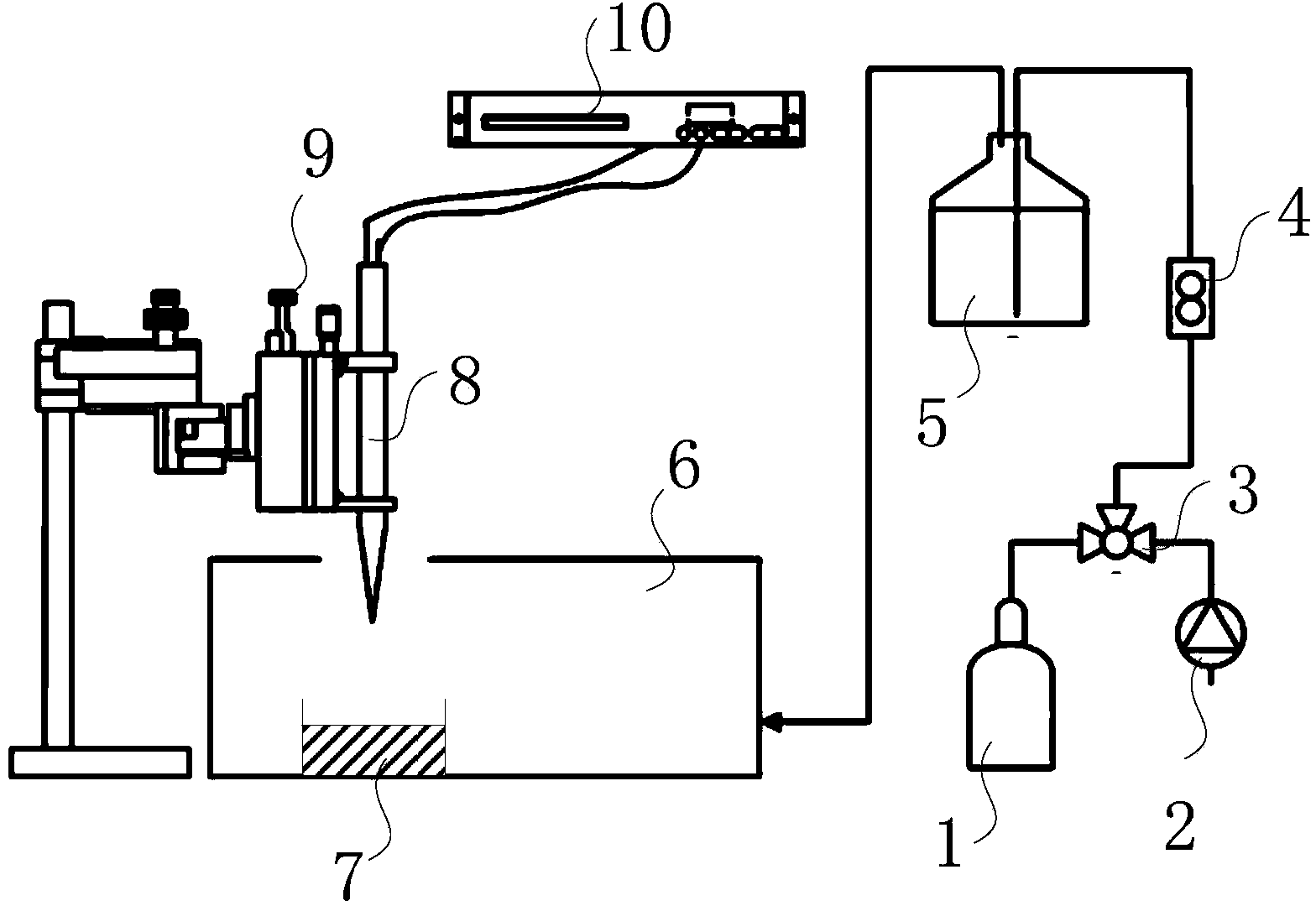

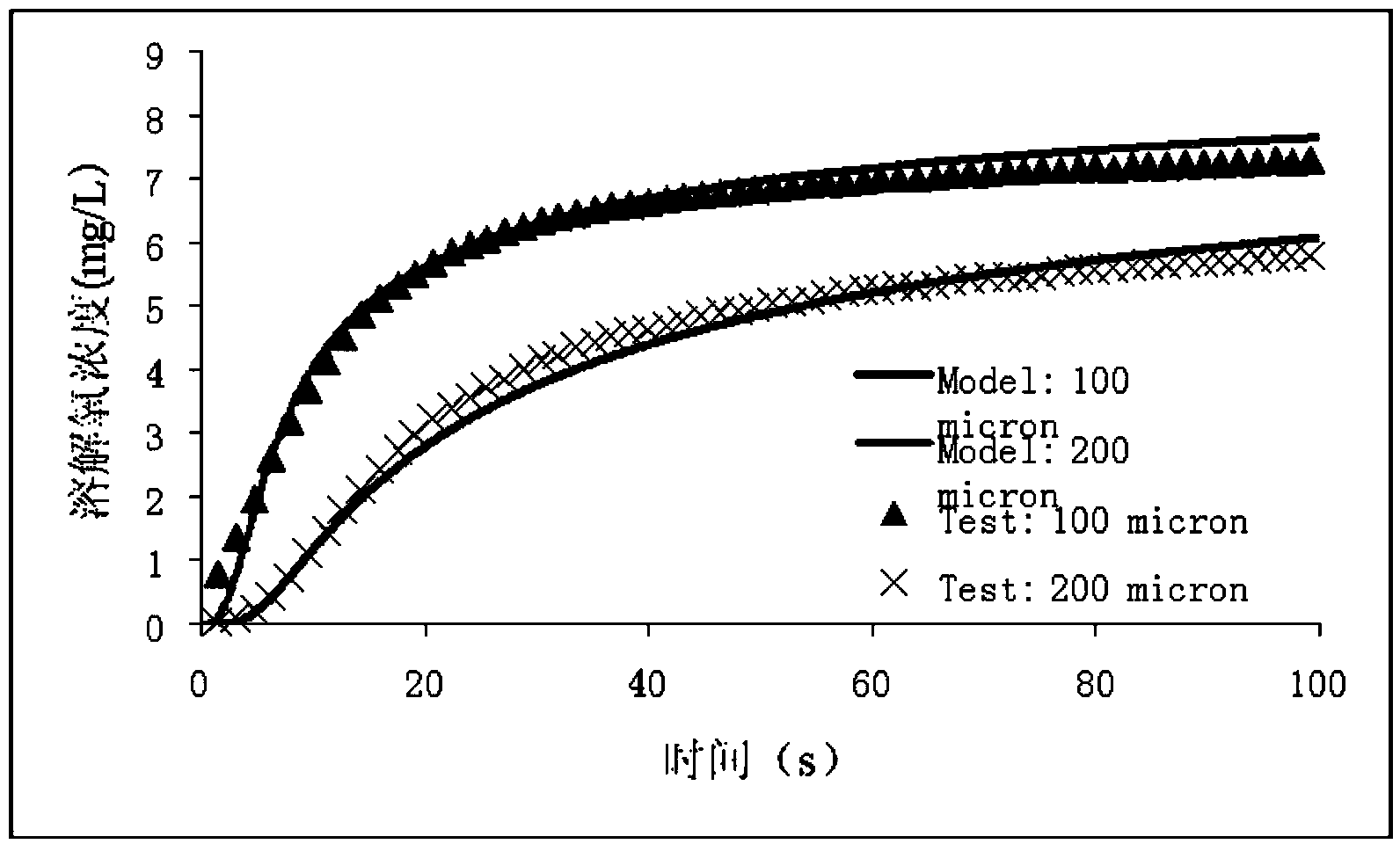

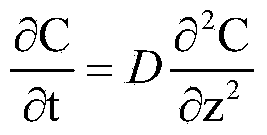

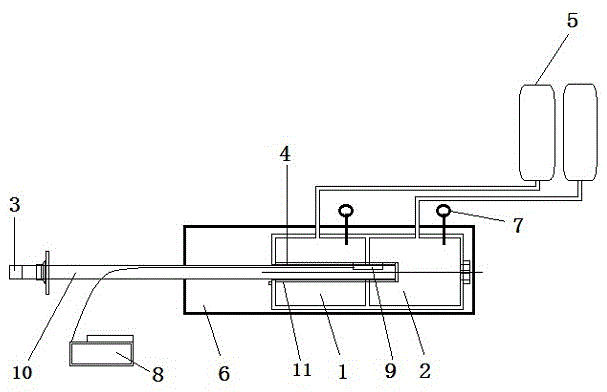

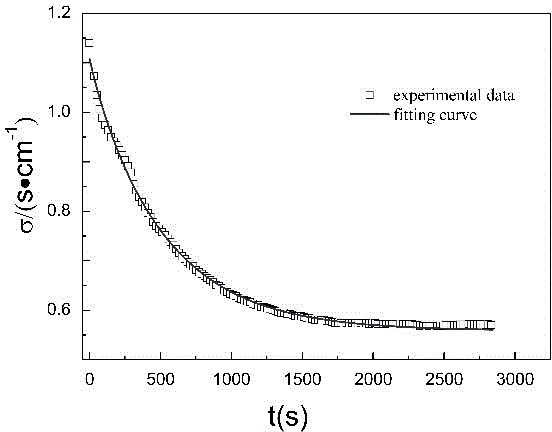

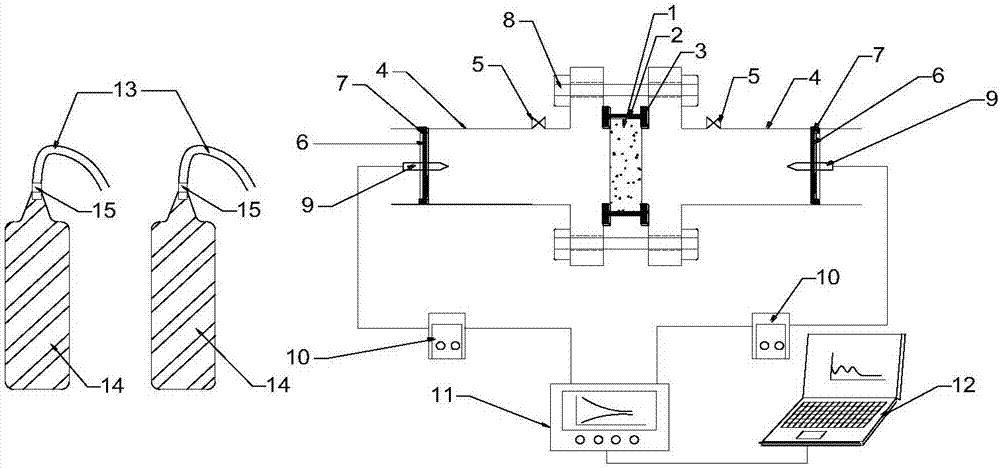

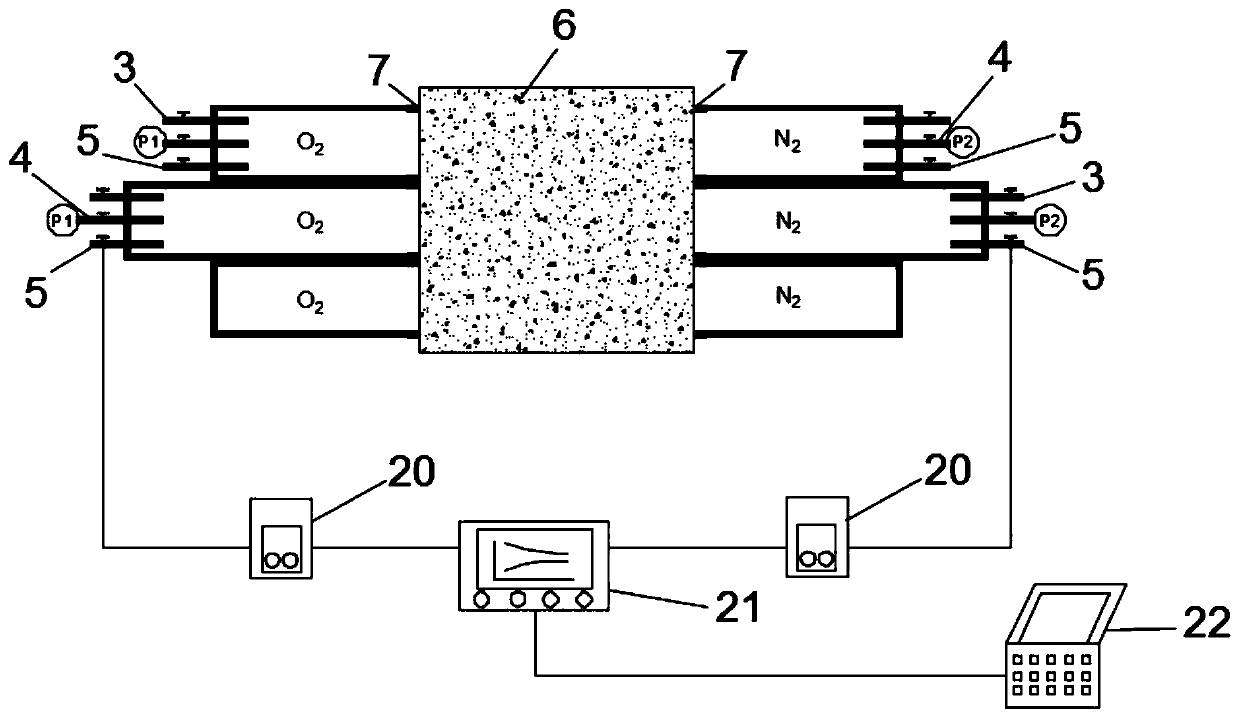

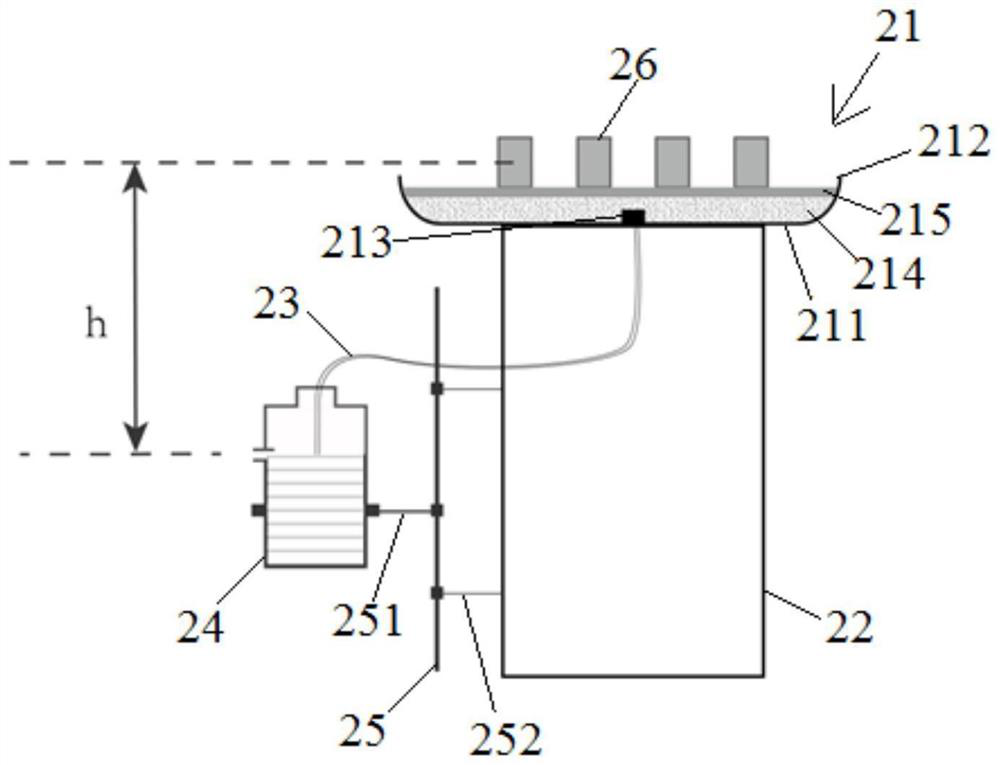

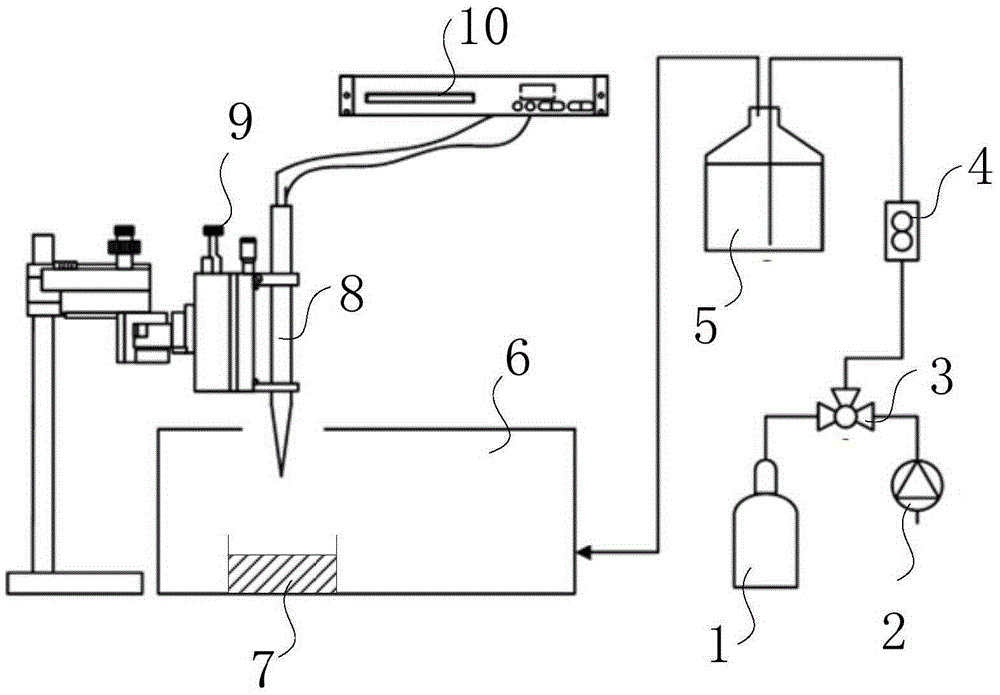

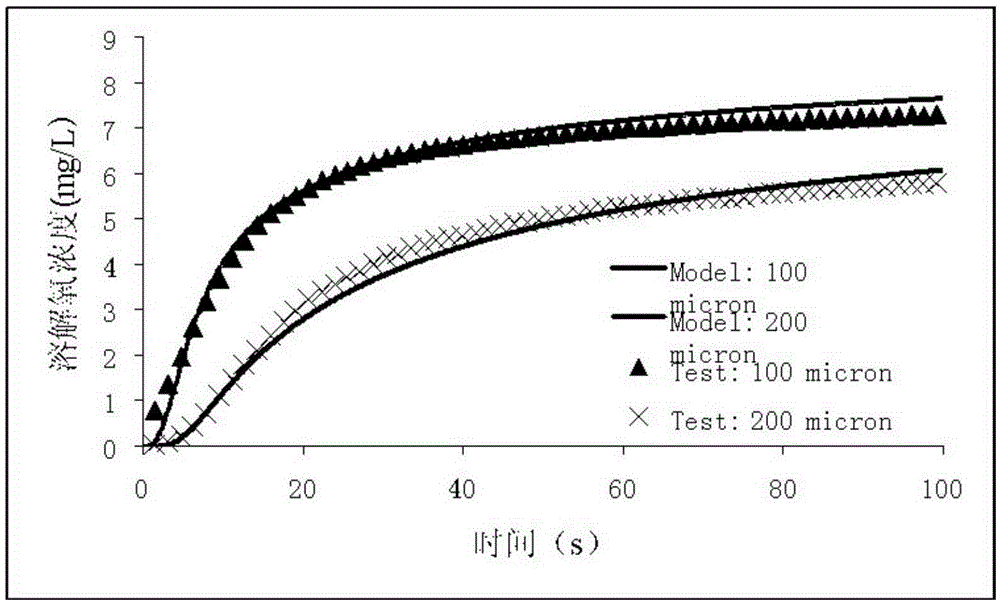

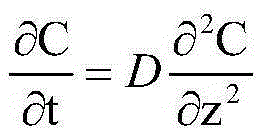

Device and method for measuring diffusion coefficient of dissolved oxygen in biological membrane

ActiveCN103969302AShort timeThe measurement result is accurateMaterial electrochemical variablesMathematical modelNitrogen gas

The invention discloses a device and method for measuring the diffusion coefficient of dissolved oxygen in a biological membrane. The device comprises a gas delivery device, an intake gas humidification bottle, a biological membrane measuring chamber and a dissolved oxygen microelectrode system. The method for measuring the diffusion coefficient of the dissolved oxygen by utilizing the device comprises the following steps: placing a to-be-measured biological membrane sample into the biological membrane measuring chamber, and introducing nitrogen to reduce the concentration of oxygen in the system to be the minimum; then changing intake gas into oxygen, and meanwhile using a dissolved oxygen microelectrode to record the curve about time-dependent change of the dissolved oxygen in the biological membrane; repeating the test in different positions and different depths of the biological membrane, so as to obtain multiple pieces of sample data; simulating the process through a mathematical model and fitting model data and data measured in the test, and calculating the diffusion coefficient of the dissolved oxygen. According to the invention, the time consumed is short, and precise chemical analysis is not required, so that the measuring result is accurate, the repeatability is good, and the system error is very small.

Owner:嘉兴华吉环保科技有限公司

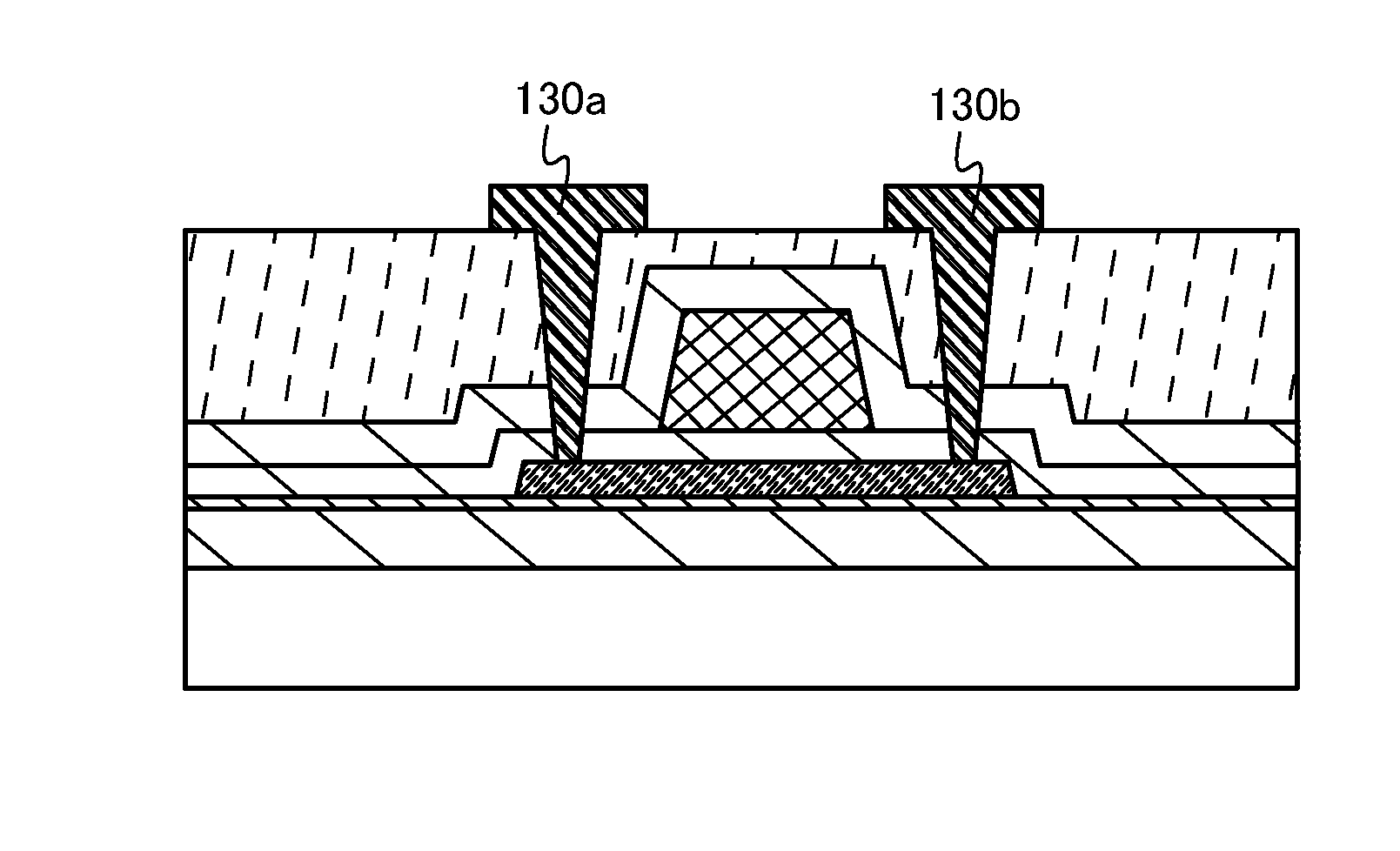

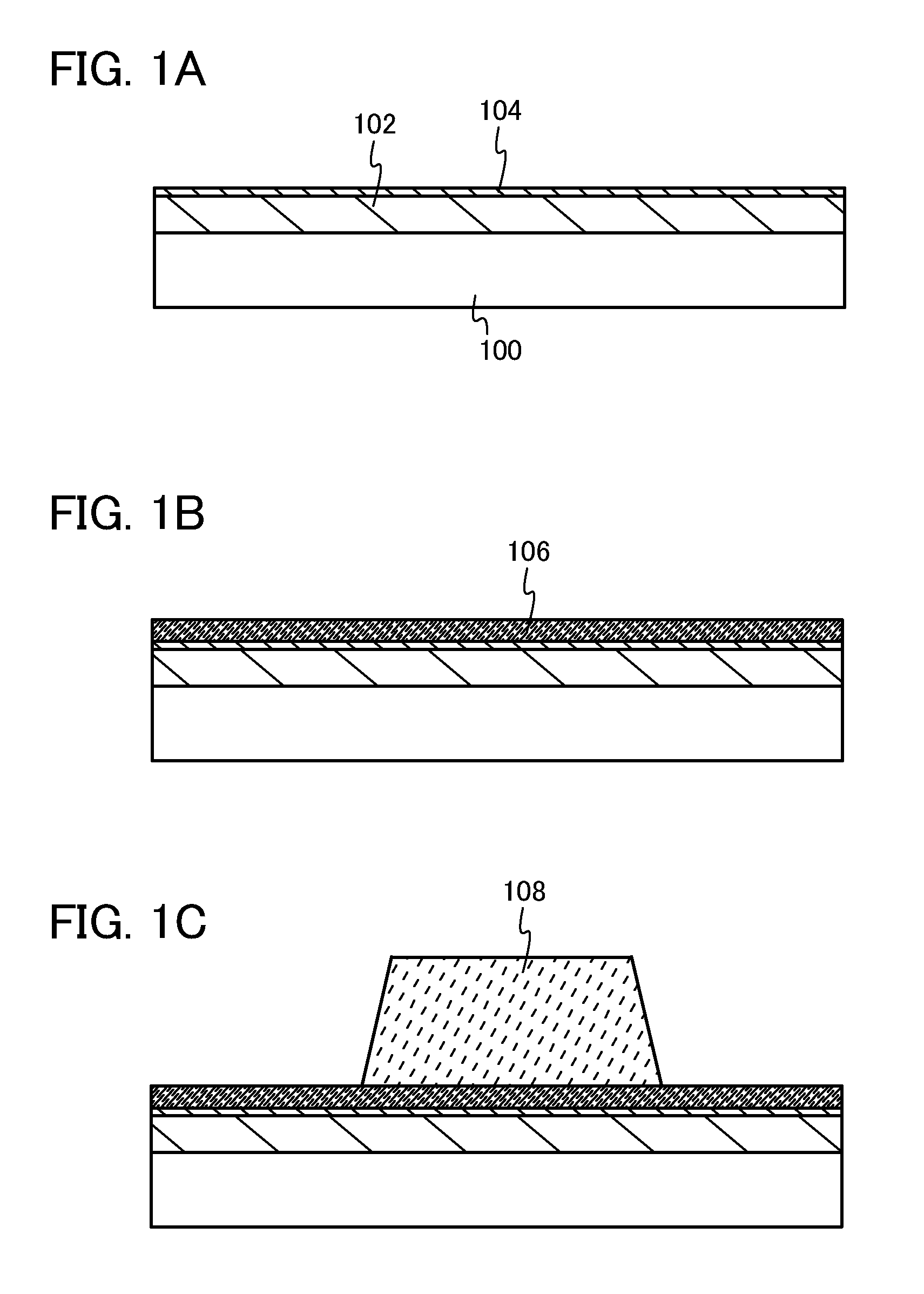

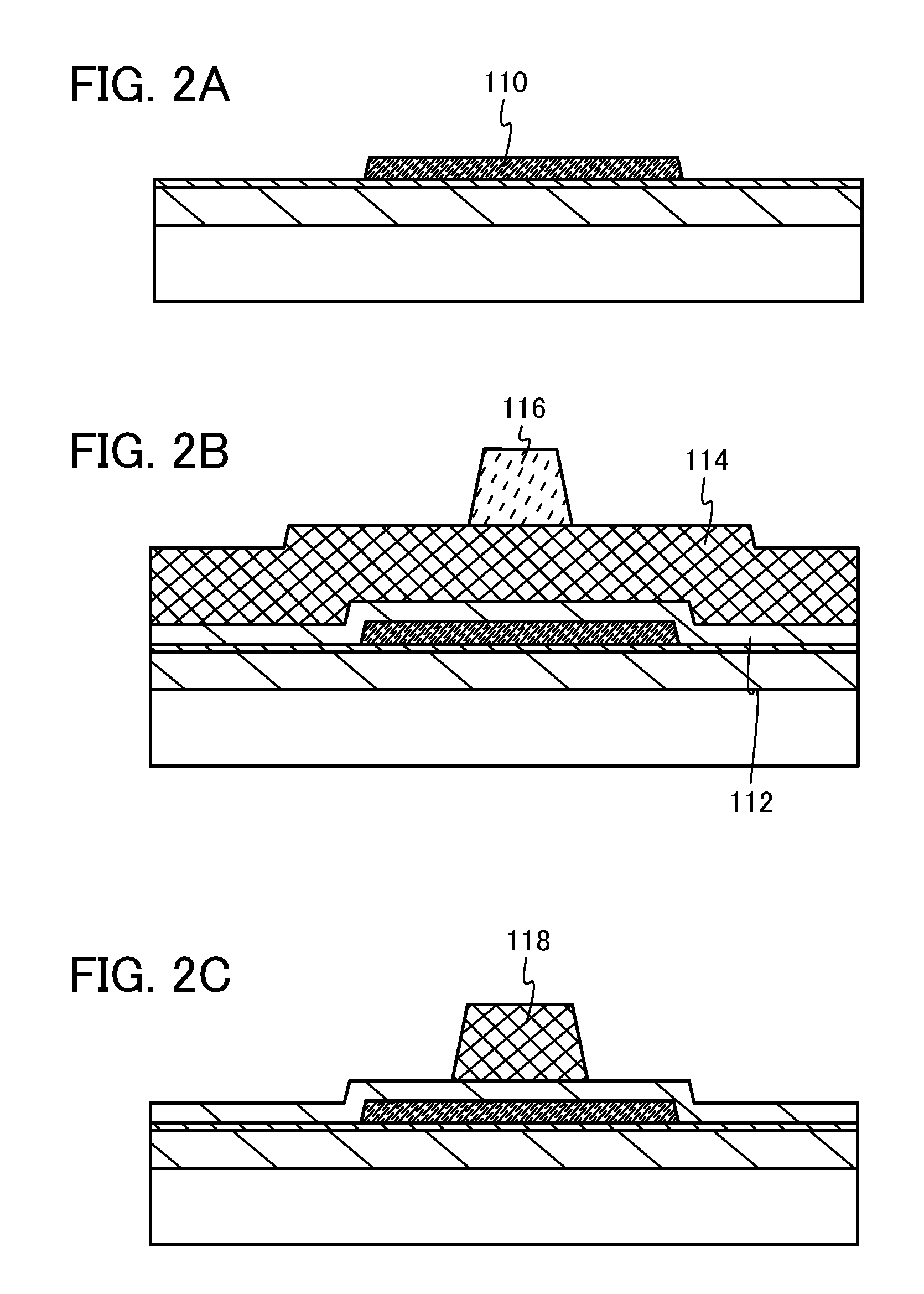

Method for manufacturing oxide semiconductor device with improved electronic properties

ActiveUS8927329B2Excellent electrical propertiesImprove mobilityTransistorSemiconductor/solid-state device manufacturingHydrogenEngineering

The amount of water and hydrogen contained in an oxide semiconductor film is reduced, and oxygen is supplied sufficiently from a base film to the oxide semiconductor film in order to reduce oxygen deficiencies. A stacked base film is formed, a first heat treatment is performed, an oxide semiconductor film is formed over and in contact with the stacked base film, and a second heat treatment is performed. In the stacked base film, a first base film and a second base film are stacked in this order. The first base film is an insulating oxide film from which oxygen is released by heating. The second base film is an insulating metal oxide film. An oxygen diffusion coefficient of the second base film is smaller than that of the first base film.

Owner:SEMICON ENERGY LAB CO LTD

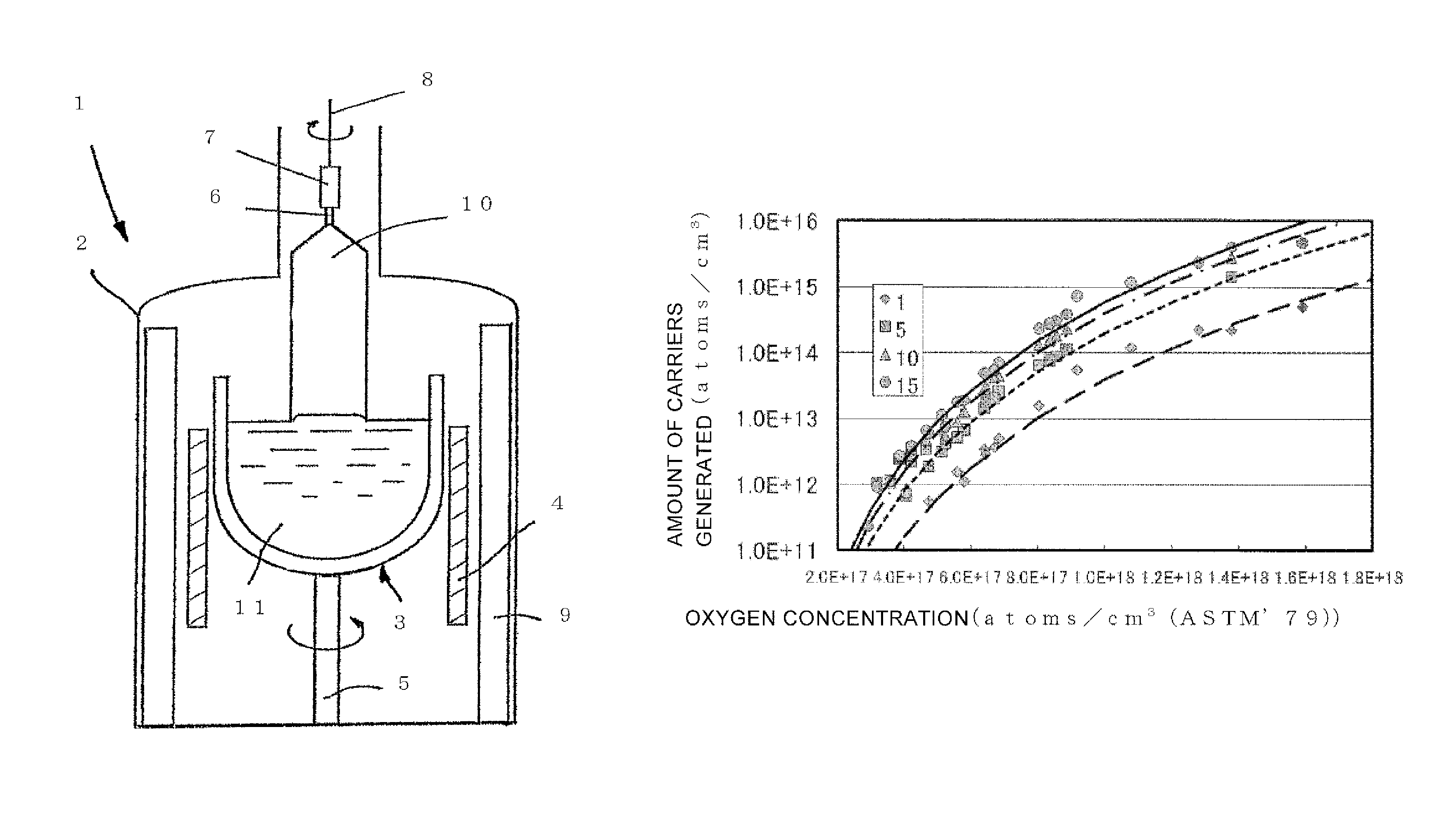

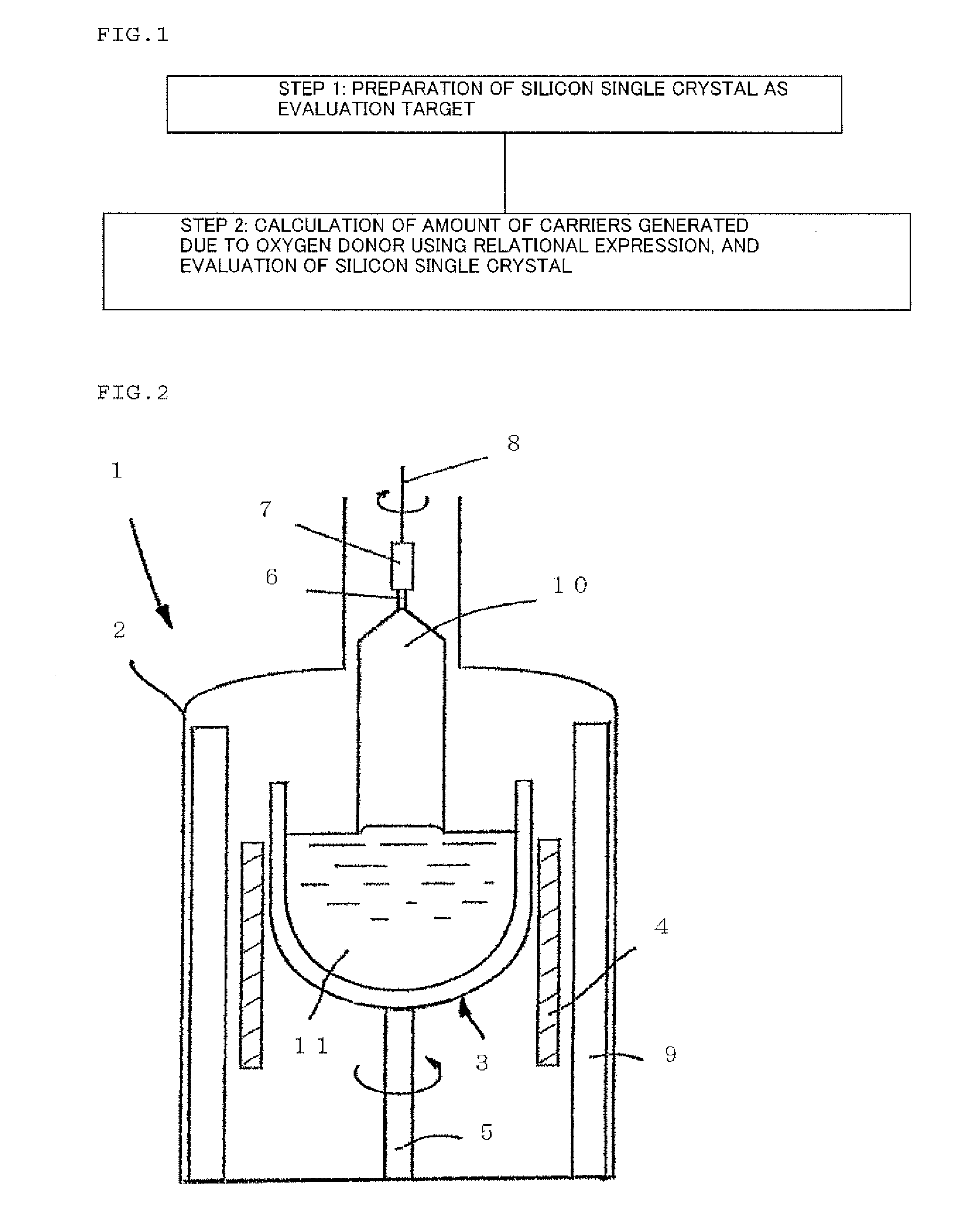

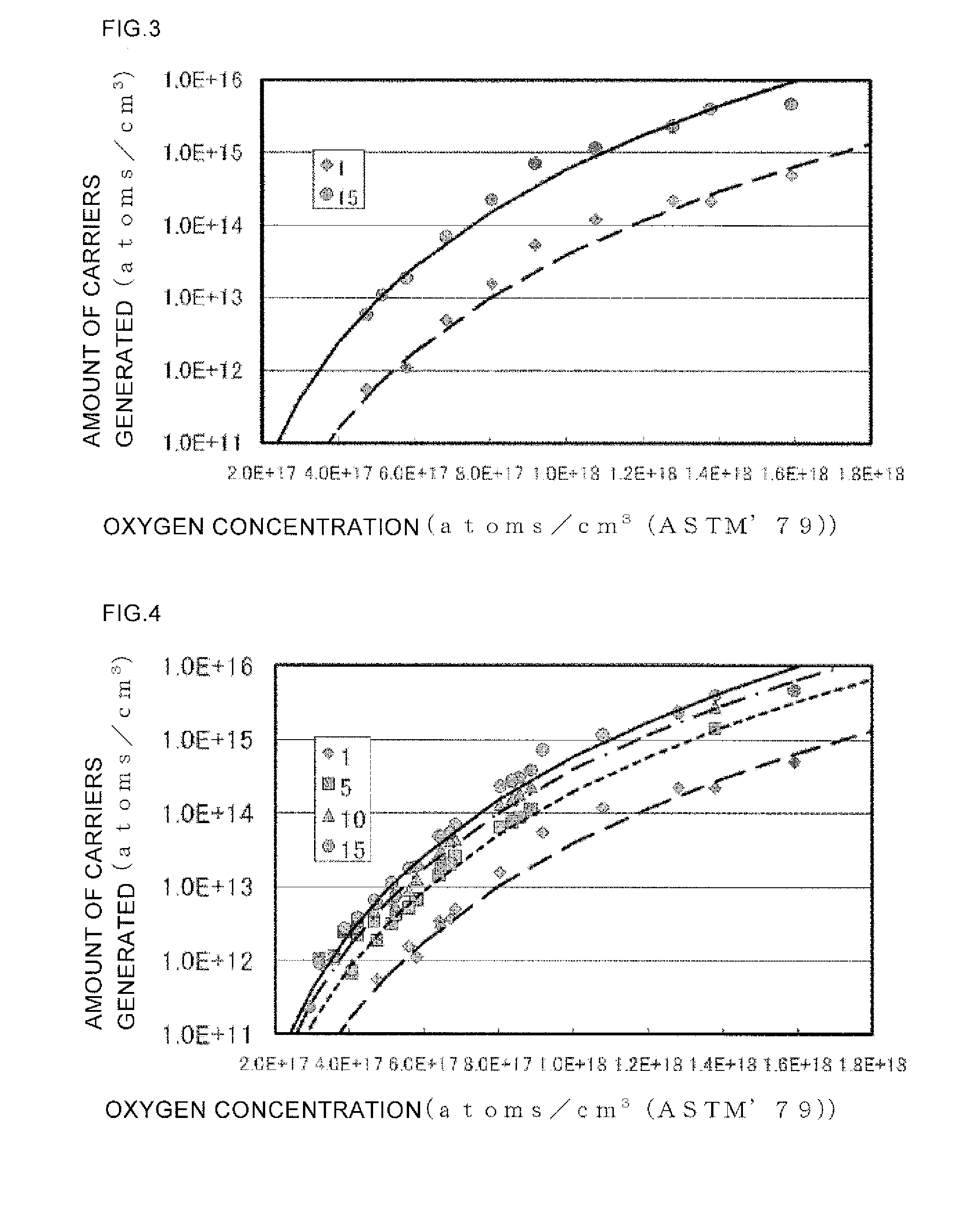

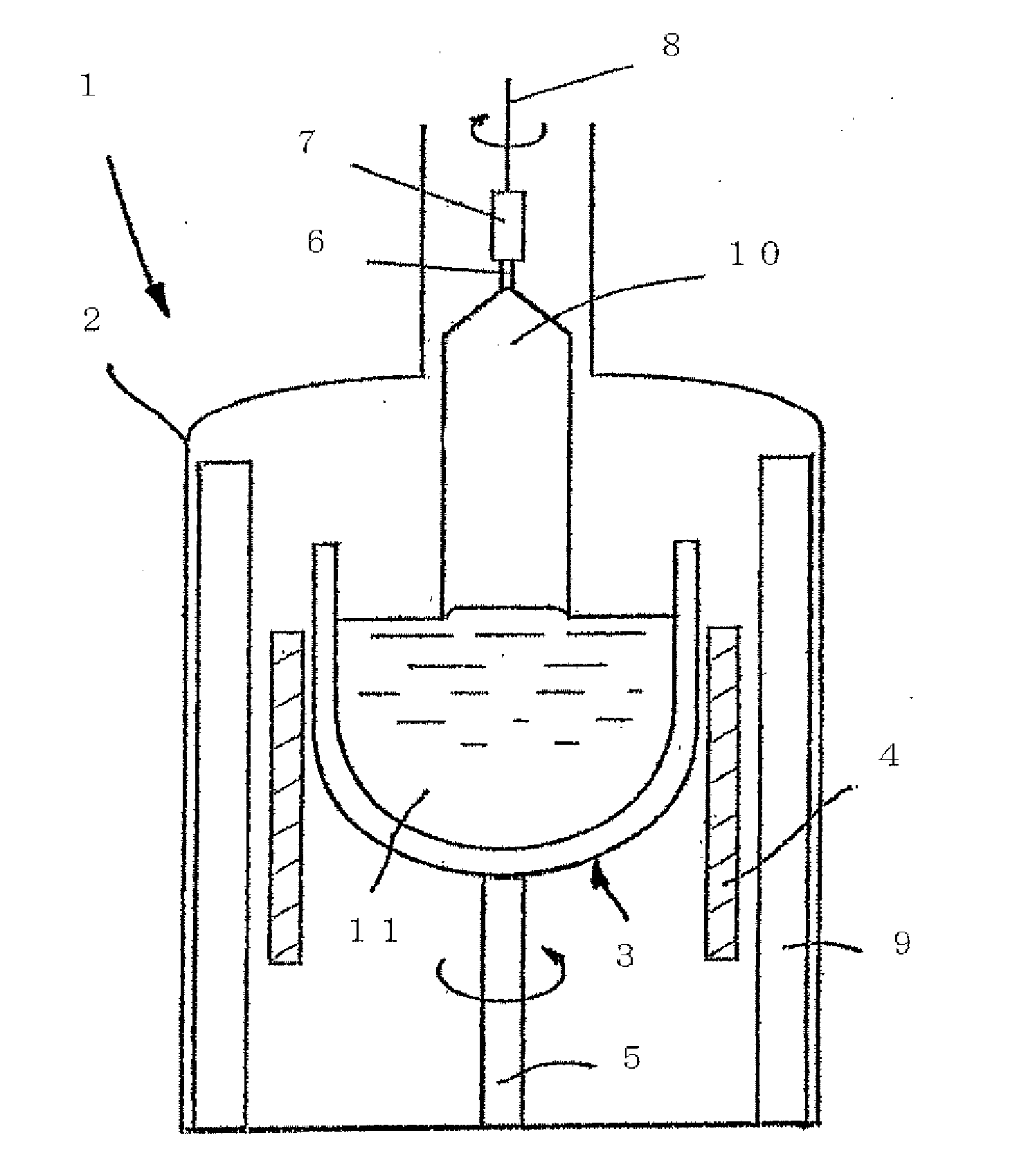

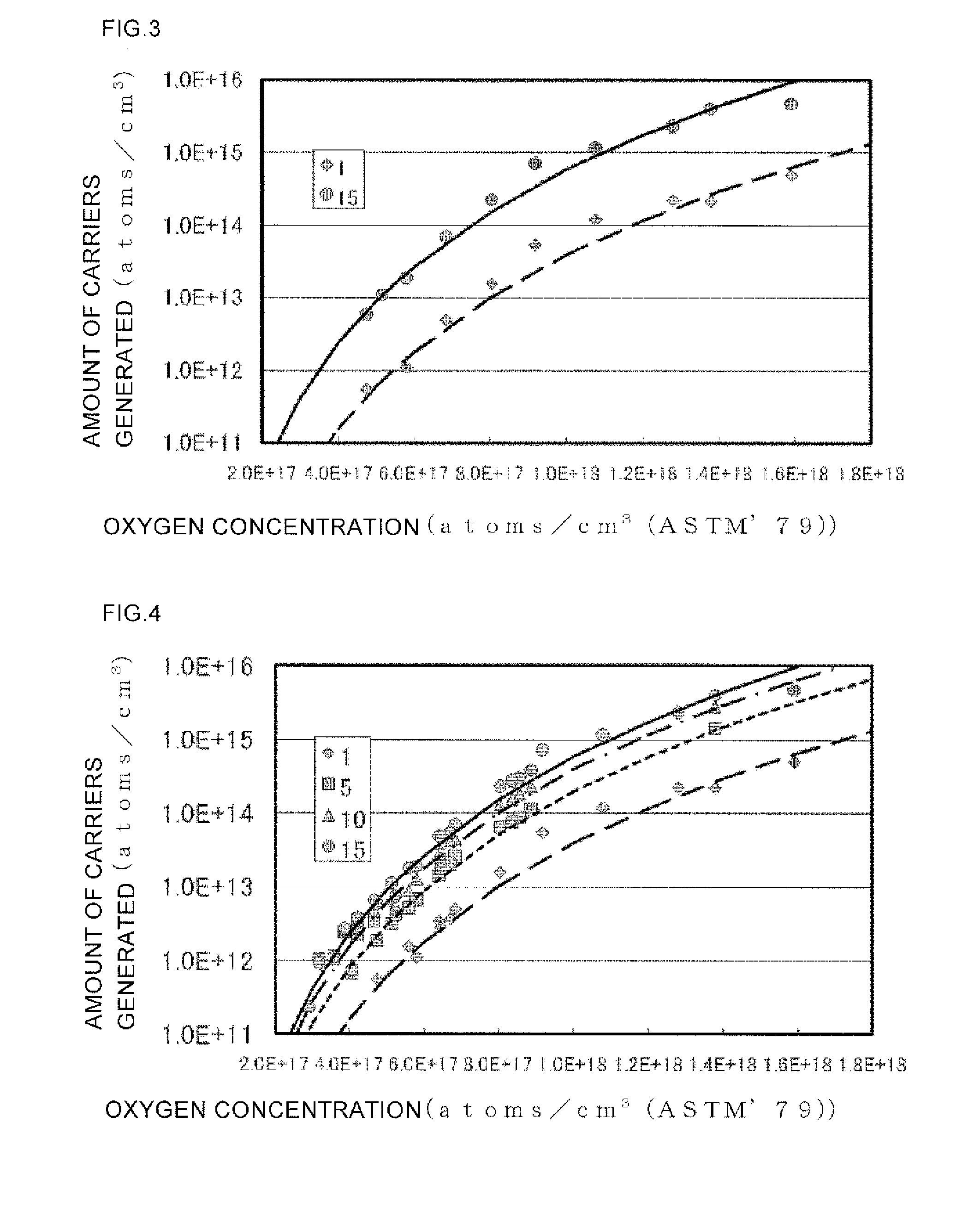

Method for evaluating silicon single crystal and method for manufacturing silicon single crystal

ActiveUS9111883B2Improve versatilityImprove accuracyPolycrystalline material growthAfter-treatment detailsCharge carrierSingle crystal

The present invention provides a method for evaluating silicon single crystal wherein an amount Δ[C] of carriers generated due to oxygen donors produced when a heat treatment is performed to the silicon single crystal is calculated and evaluated, the amount Δ[C] being calculated from oxygen concentration [Oi] in the silicon single crystal, a temperature T of the heat treatment, a time t of the heat treatment, and an oxygen diffusion coefficient D(T) at the temperature T by using the following relational expression:Δ[C]=α[Oi]5×exp(−β·D(T)·[Oi]·t)(where α and β are constants). As a result, there is provided a method that enables evaluating an amount of carriers generated due to oxygen donors in silicon single crystal in a further versatile manner.

Owner:SHIN-ETSU HANDOTAI CO LTD

Method for evaluating silicon single crystal and method for manufacturing silicon single crystal

ActiveUS20140363904A1Improve versatilityImprove accuracyPolycrystalline material growthAfter-treatment detailsPhysical chemistrySingle crystal

The present invention provides a method for evaluating silicon single crystal wherein an amount Δ[C] of carriers generated due to oxygen donors produced when a heat treatment is performed to the silicon single crystal is calculated and evaluated, the amount Δ[C] being calculated from oxygen concentration [Oi] in the silicon single crystal, a temperature T of the heat treatment, a time t of the heat treatment, and an oxygen diffusion coefficient D(T) at the temperature T by using the following relational expression:Δ[C]=α[Oi]5×exp(−β·D(T)·[Oi]·t) (where α and β are constants). As a result, there is provided a method that enables evaluating an amount of carriers generated due to oxygen donors in silicon single crystal in a further versatile manner.

Owner:SHIN-ETSU HANDOTAI CO LTD

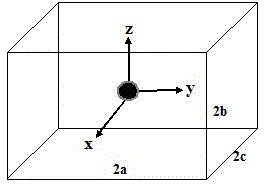

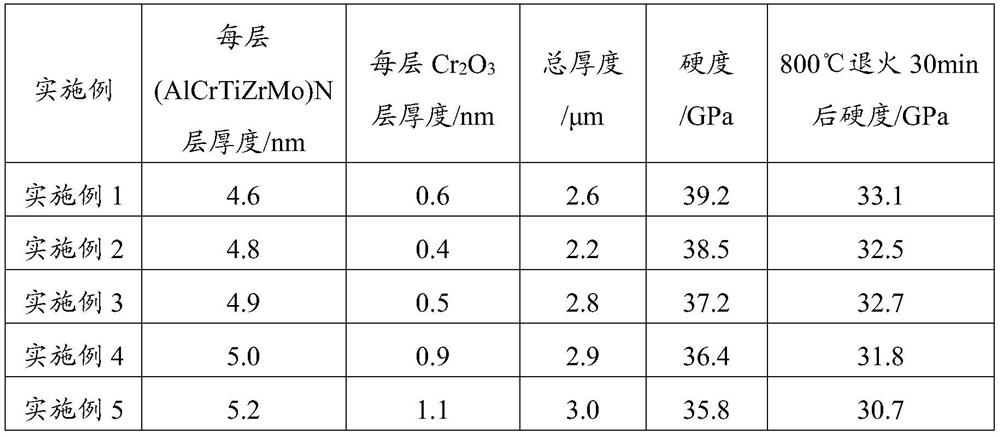

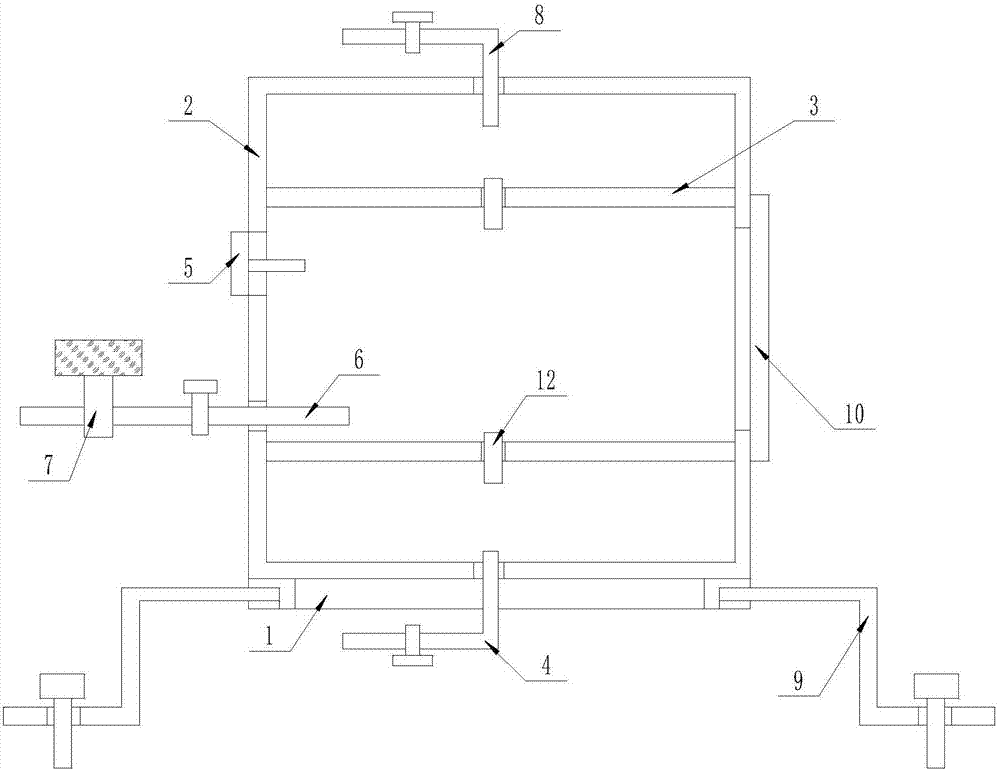

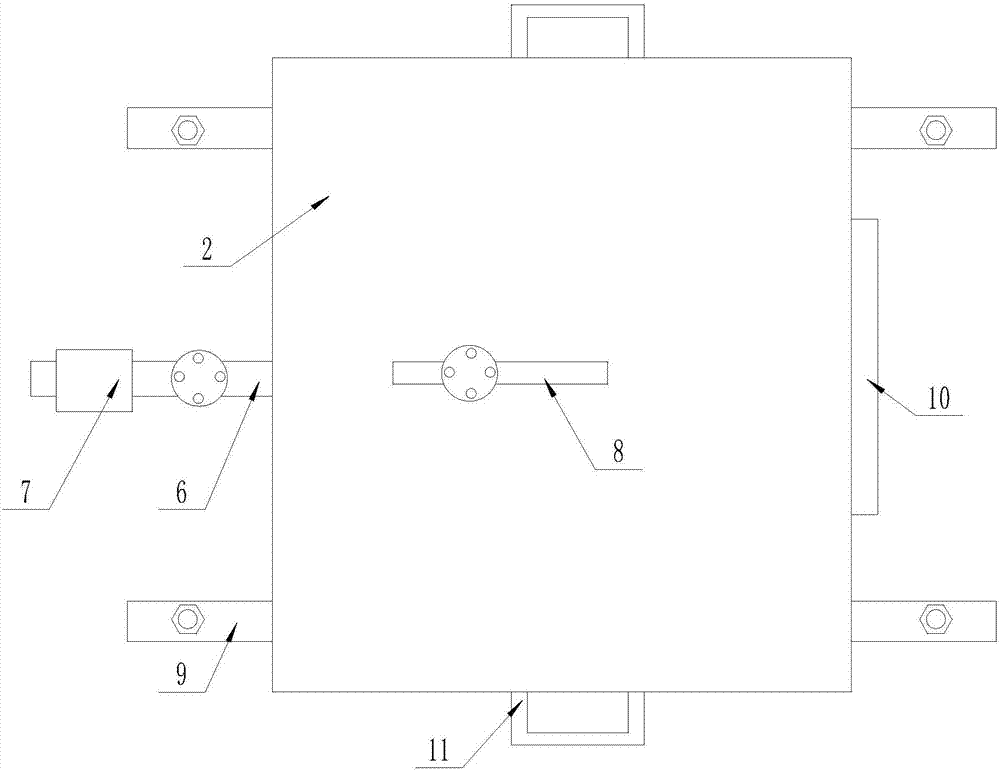

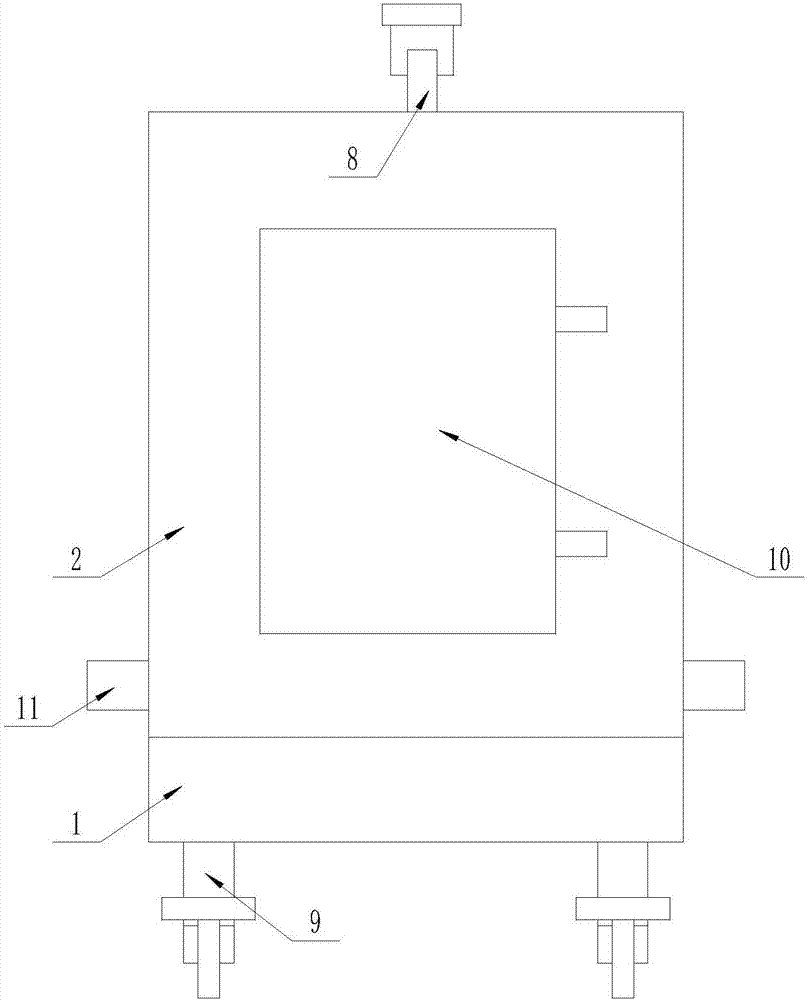

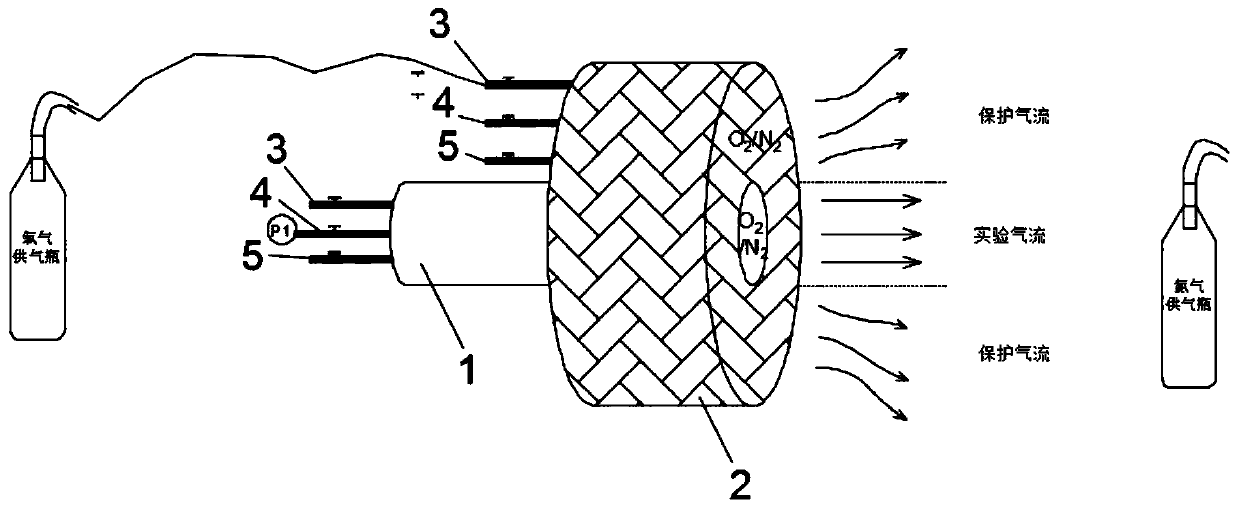

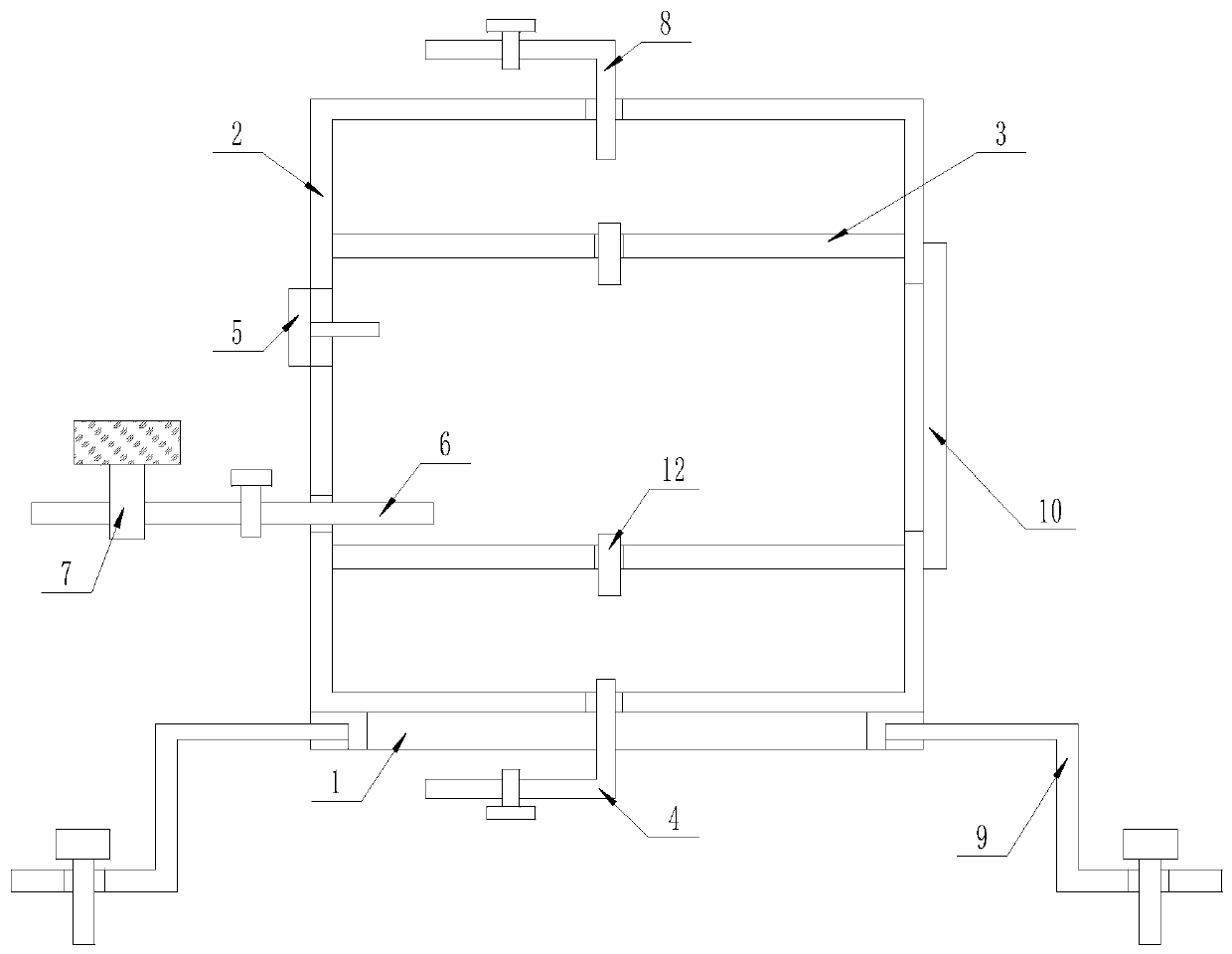

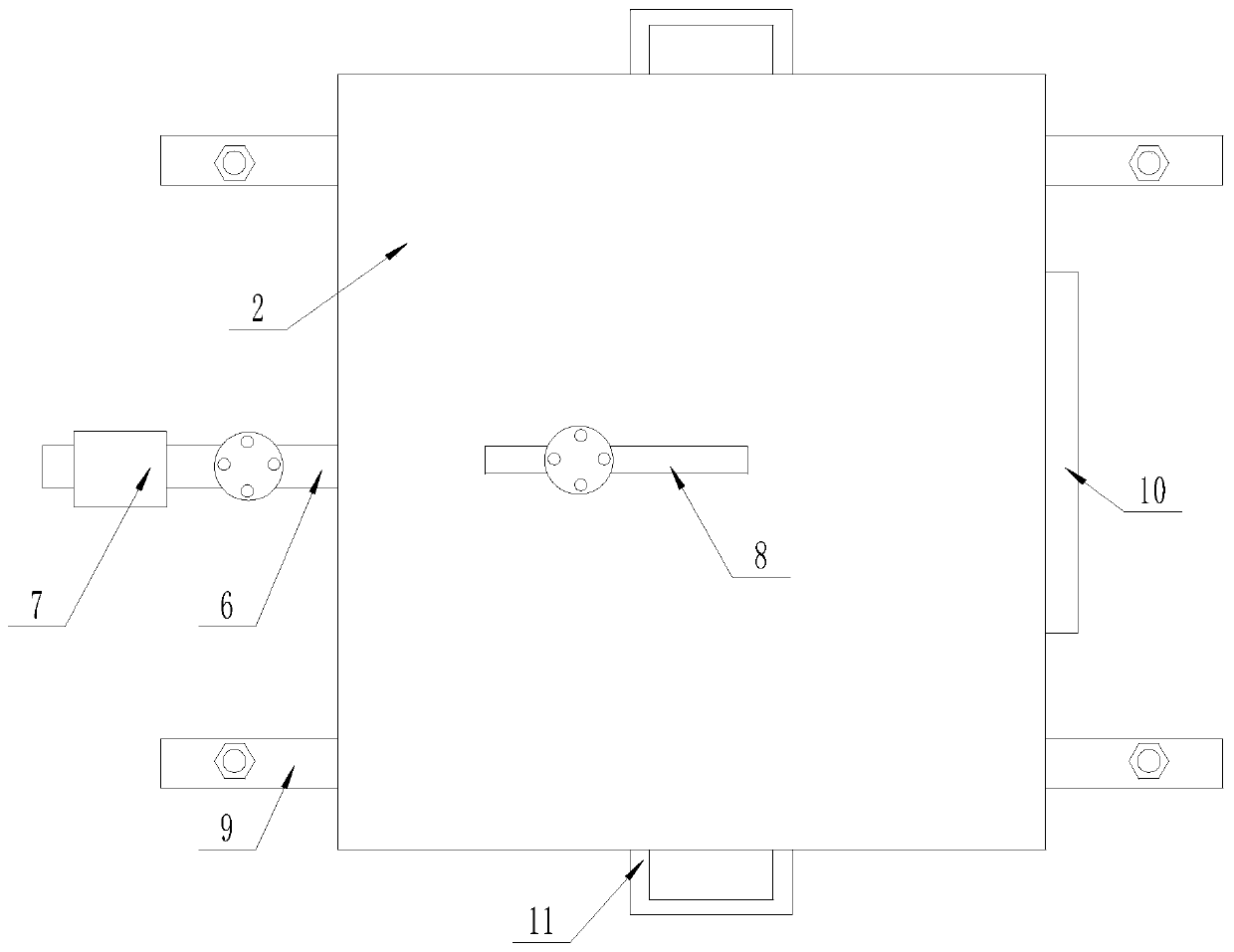

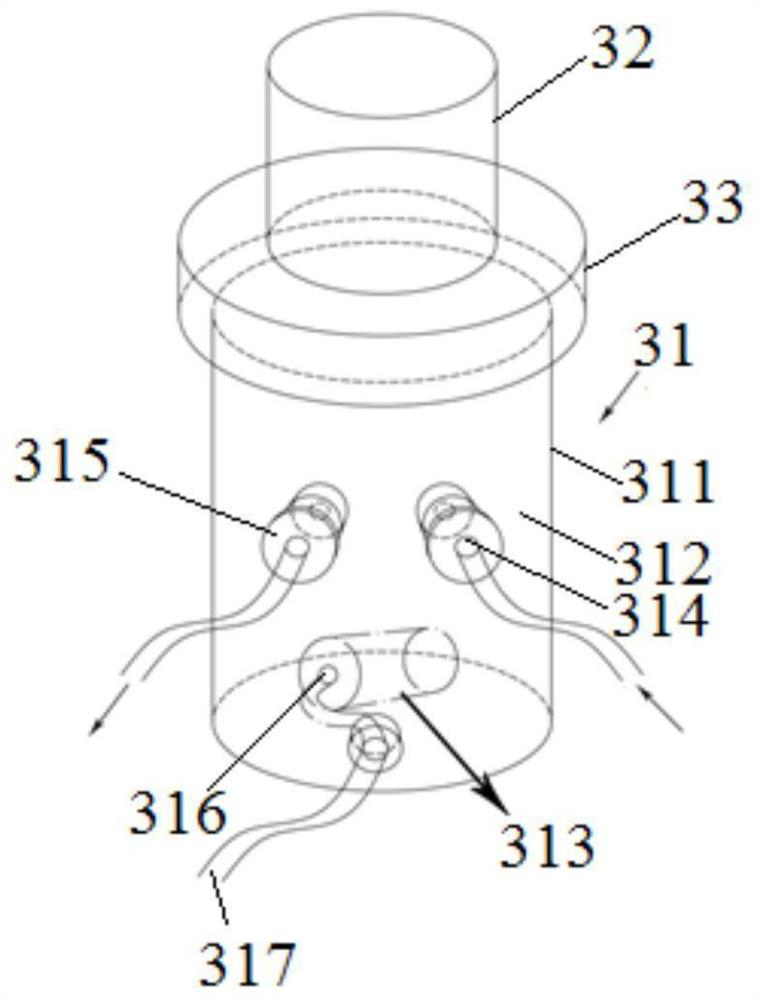

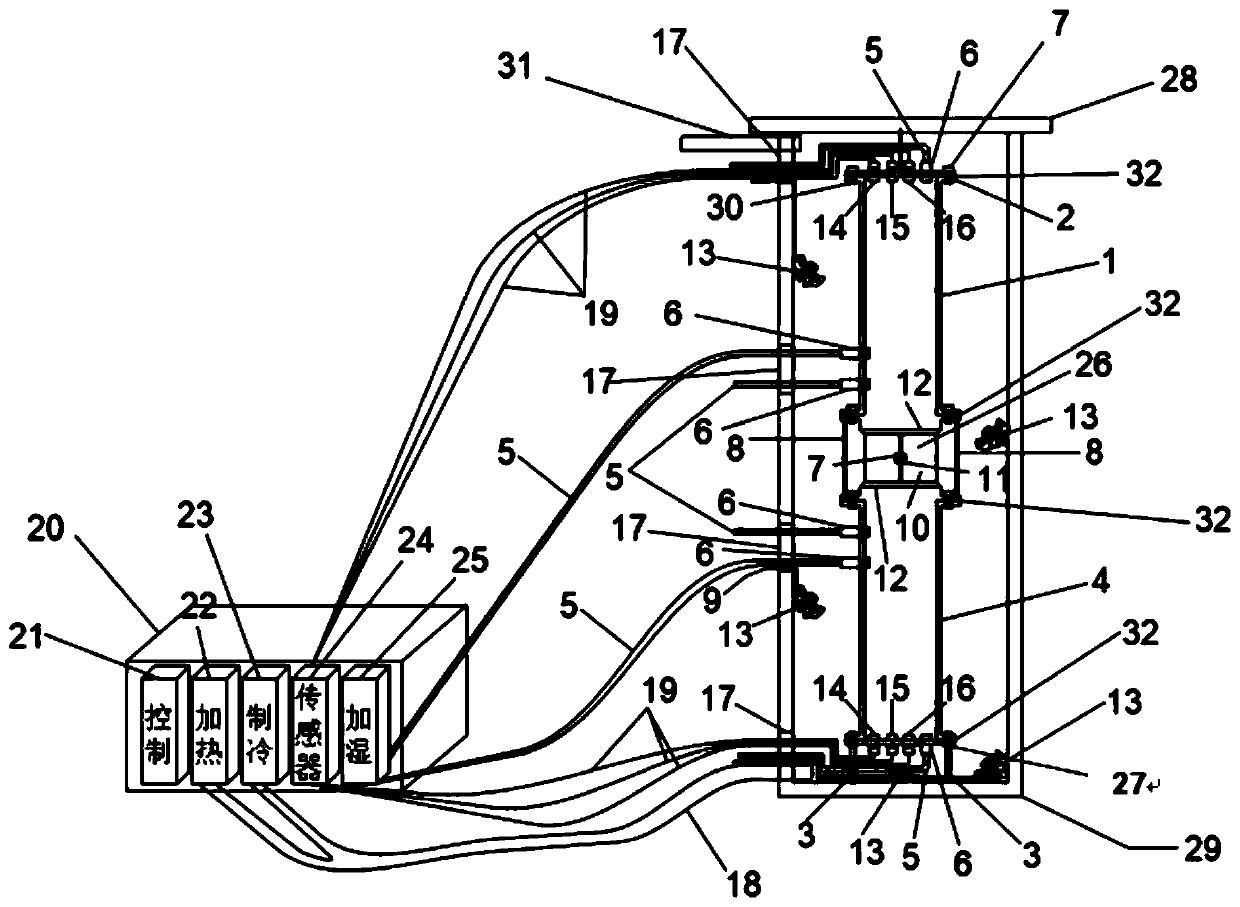

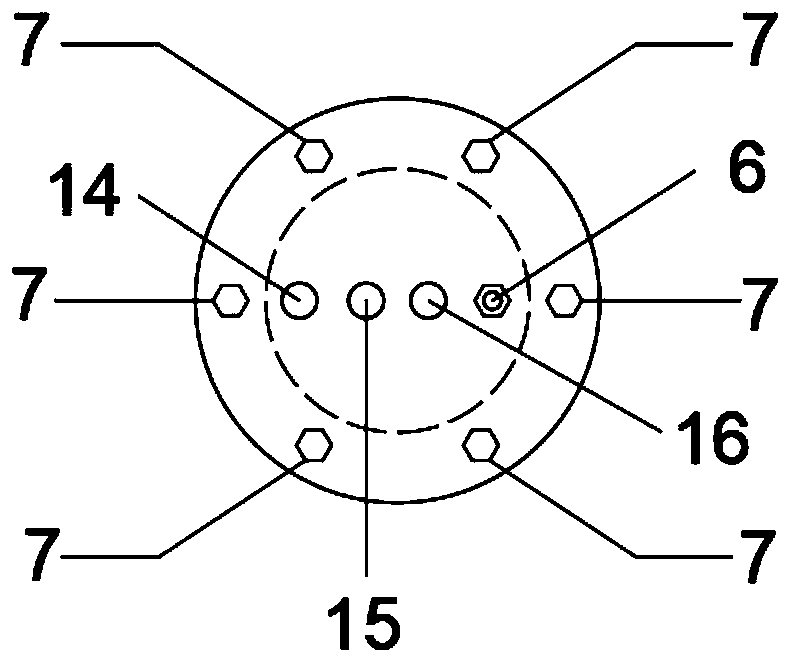

Sliding type device for measuring oxygen exchange coefficient and oxygen diffusion coefficient

ActiveCN104792664AAccurate determination of oxygen exchange coefficientAccurate determination of oxygen diffusion coefficientSurface/boundary effectData analysis systemThermal expansion

The invention discloses a sliding type device for measuring the oxygen exchange coefficient and the oxygen diffusion coefficient. The sliding type device comprises an experimental platform device, a material conductivity test device, an input and output device, a data analysis system, a gas mixing device, an atmosphere pre-heating device and a gas detecting device, wherein a to-be-measured experimental material sample arranged on a sample table is switched in different experimental cavity atmospheres in the whole testing process, a gap between a sliding shaft and each shaft hole in the cavity wall is reduced through thermal expansion at the high temperature by the aid of a sealing part machined precisely, and accordingly, sealing between cavities is realized; a gas mixing device is used for providing different oxygen partial pressure test gases; an atmosphere pre-heating device is used for controlling the gas temperature; the data analysis system is used for performing signal data fitting computation to obtain the oxygen exchange coefficient and the oxygen diffusion coefficient. According to the sliding type device for measuring the oxygen exchange coefficient and the oxygen diffusion coefficient, signal data are collected by the test device, so that data of the oxygen exchange coefficient and the oxygen diffusion coefficient of the material are obtained accurately and rapidly, and the material performance data are obtained.

Owner:SHANGHAI UNIV

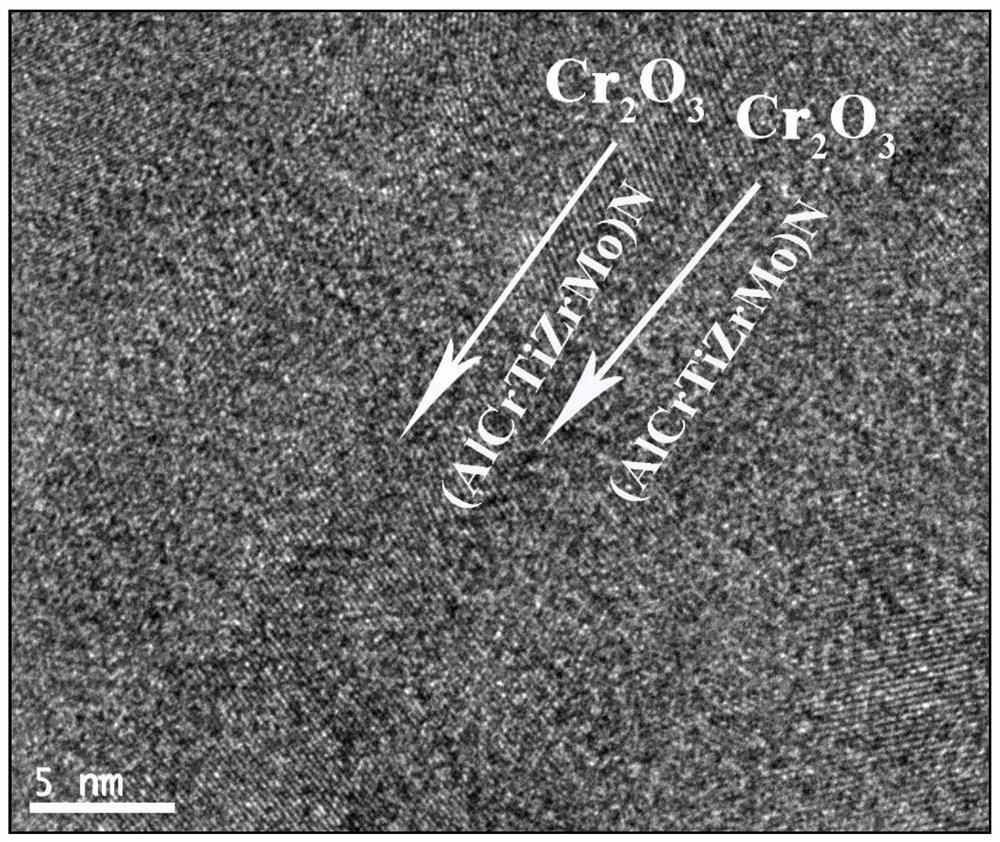

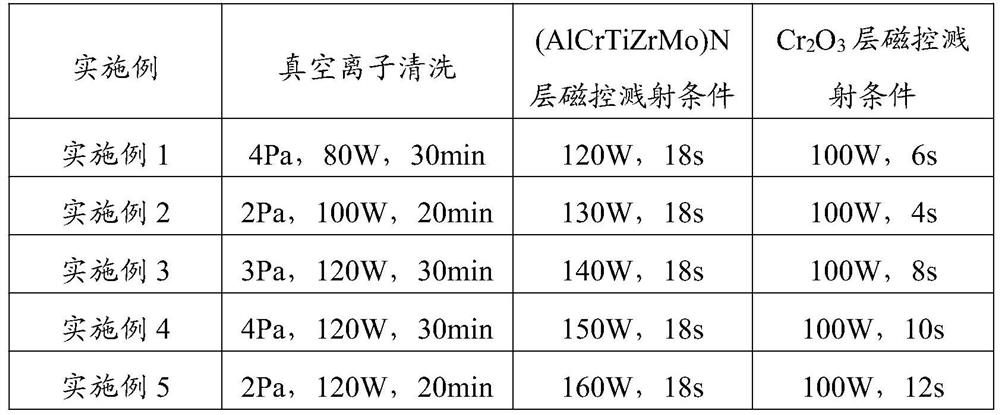

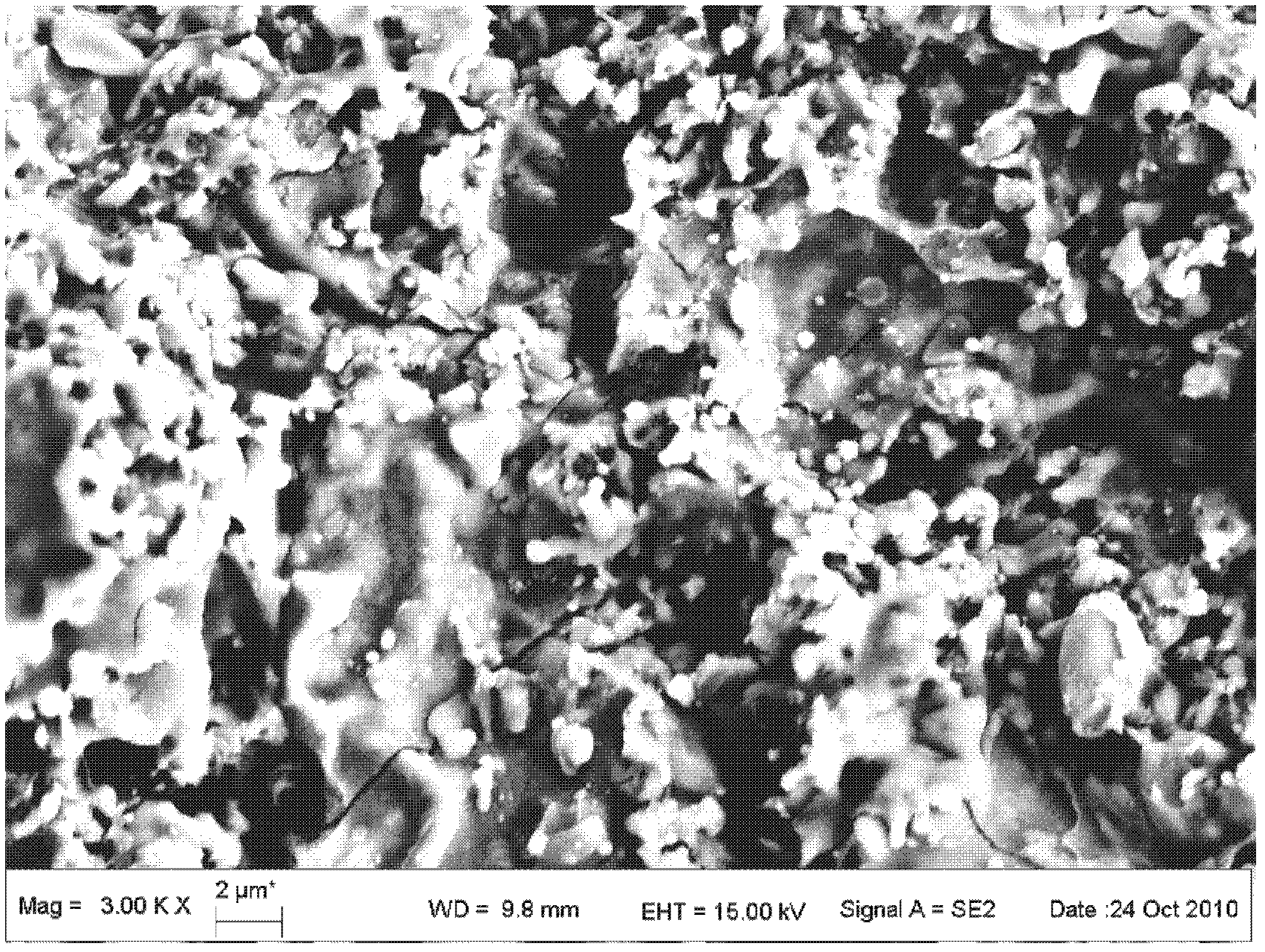

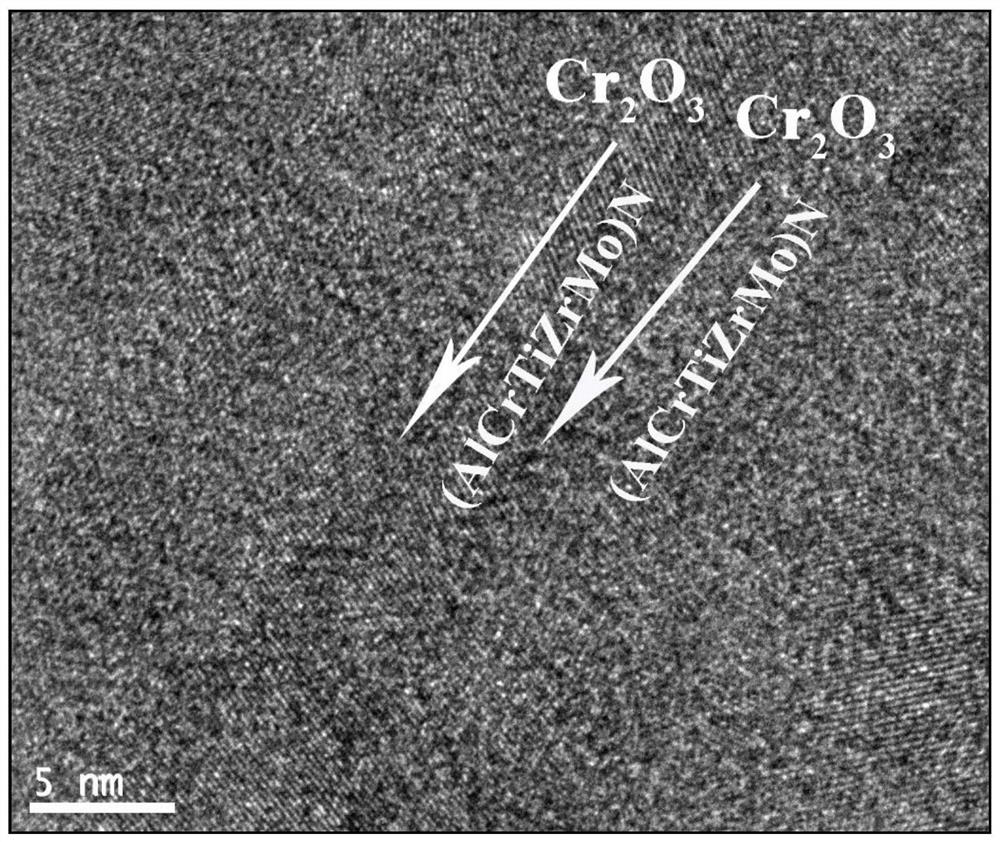

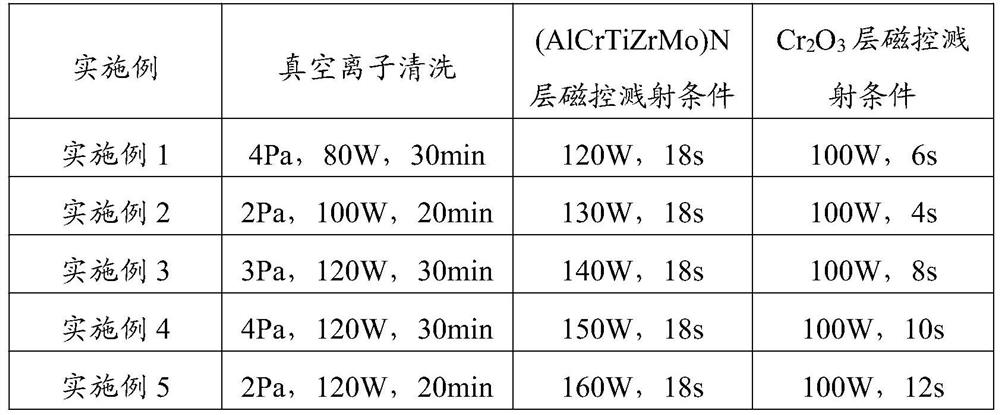

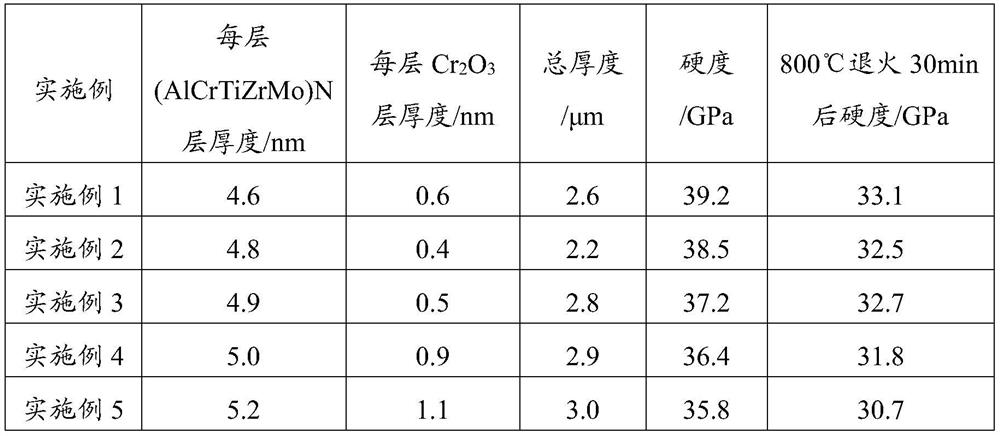

Nanometer multilayer coating, preparation method thereof and cutter with surface coated with nanometer multilayer coating

ActiveCN111962036AHigh hardnessImprove thermal stabilityVacuum evaporation coatingSputtering coatingHeat stabilityOxygen diffusion coefficient

The invention provides a nanometer multilayer coating, a preparation method of the nanometer multilayer coating and a cutter with the surface coated with the nanometer multilayer coating, and belongsto the technical field of protective coatings. The nanometer multilayer coating provided by the invention comprises (AlCrTiZrMo)N nanometer layers and Cr2O3 nanometer layers which are sequentially andalternately laminated on the surface of a substrate. According to the nanometer multilayer coating provided by the invention, a coherent boundary is formed between the (AlCrTiZrMo)N nanometer layersand the Cr2O3 nanometer layers, then dislocation movement is hindered, and the hardness of the nanometer multilayer coating is high; and due to the fact that modulation layers are the Cr2O3 nanometerlayers with low oxygen diffusion coefficient, the thermal stability of the nanometer multilayer coating is better than that of the (AlCrTiZrMo)N single-layer coating. The nanometer multilayer coatingprovided by the invention has both high hardness and high thermal stability, the defects in the use of a traditional tool coating can be made up, the research range of the tool coating is widened, andthe performance requirements of high-speed cutting and dry cutting are satisfied.

Owner:上海工具厂有限公司 +1

Method for determining oxygen diffusion coefficient in cement-based material and test device

The invention discloses a method for determining an oxygen diffusion coefficient in a cement-based material. The method comprises the following steps of (1) preparation of a to-be-tested specimen of a cement-based material; (2) connection of a test device; and (3) determination of the oxygen diffusion coefficient Df in the cement-based material. The invention further provides a test device for determining the oxygen diffusion coefficient in the cement-based material. The test device comprises an air supply system, a specimen, left and right gas chambers and a sensing test system. The driving force of oxygen diffusion in the whole process is only concentration gradient, so that the diffusion coefficient of the oxygen in the specimen of the cement-based material can be determined, the measurement method is simple and data are accurate and reliable. A data foundation can be provided for further research of the corrosion process of the oxygen on steel rebar in the cement-based material through determining the transmission rule of the oxygen in the cement-based material.

Owner:ZHEJIANG UNIV OF TECH

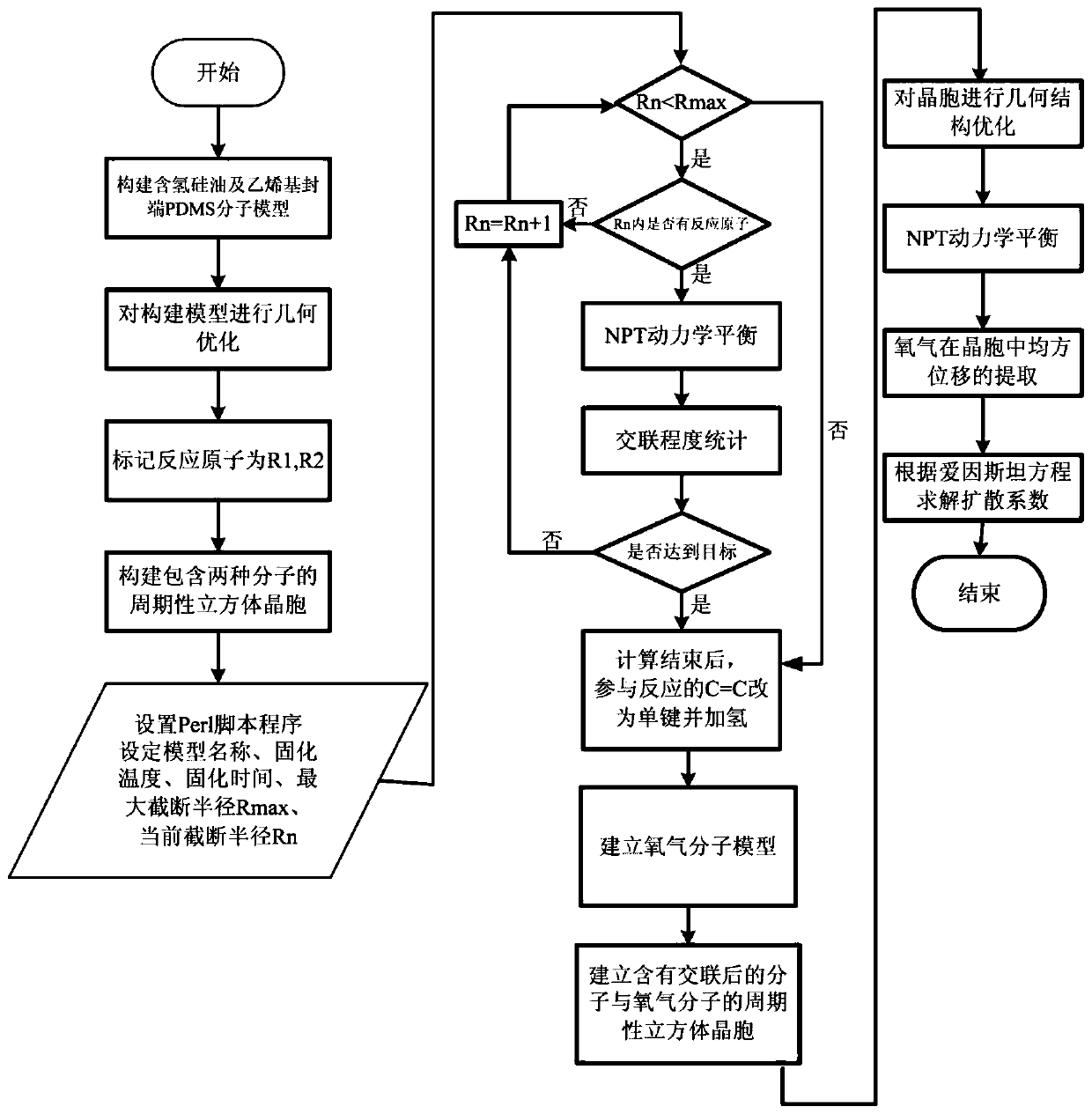

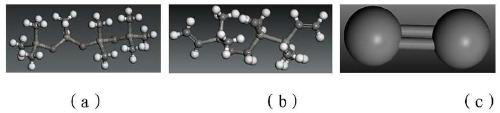

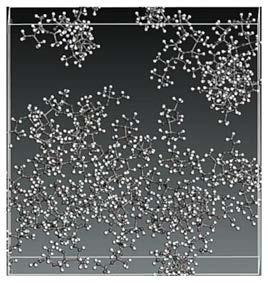

Method for calculating oxygen diffusion coefficient of polydimethylsiloxane

ActiveCN111192628AIncrease the diffusion coefficientInstrumentsMolecular structuresPolymer scienceCross linker

The invention discloses a method for calculating an oxygen diffusion coefficient of polydimethylsiloxane. The method comprises the following specific steps: establishing a hydrogen-containing siliconeoil cross-linking agent and vinyl-terminated PDMS molecular structure model and then carrying out geometric optimization; marking the reaction atoms; constructing a molecular model and performing geometric optimization to obtain unit cells; according to the mechanism of the cross-linking reaction, realizing automatic cross-linking of reaction chemical bonds in the hydrogen-containing silicone oilcross-linking agent and the vinyl-terminated PDMS prepolymer through a Perl script program; after a cross-linking model is obtained, newly building oxygen molecules, and building unit cells of an oxygen-containing molecular model and a cross-linking molecular model; carrying out NPT dynamic calculation on the optimized unit cell; obtaining the mean square displacement of the oxygen in the unit cell; and obtaining the diffusion coefficient of the oxygen in the cross-linked molecules through an Einstein equation. According to the method, the crosslinking process of the reaction can be analyzedfrom the molecular perspective, and the process conditions for improving the oxygen diffusion coefficient in the PDMS film preparation process are further obtained.

Owner:XIAN UNIV OF TECH

Solid oxide fuel cell structure and preparation method thereof

InactiveCN102347495AImprove adsorption capacityImproves the performance of dissociated oxygenCell electrodesSolid electrolyte fuel cellsSurface exchange coefficientFuel cells

The invention belongs to the field of solid oxide fuel cells, in particular relates to a solid oxide fuel cell structure and a preparation method thereof. The cell structure comprises a cell cathode layer, an electrolyte layer and a cell anode layer in sequence from top to bottom, wherein the cell cathode layer is divided into a PrBaCo2O5 layer and an LSM (La0.8S0.2MnO3) layer from top to bottom; the electrolyte layer is YSZ (Yttria Stabilized Zirconia); the cell anode layer is Ni-YSZ; and the thickness of the PrBaCo2O5 layer is 2-4 microns. Because PrBaCo2O5 has higher catalytic performance, oxygen diffusion coefficients, surface exchange coefficients and oxygen ion migration capability, the oxygen adsorbing capability and oxygen dissociating capability of a cathode can be improved by adopting a PrBaCo2O5-LSM / YSZ / Ni-YSZ structure and material system; and the solid oxide fuel cell structure has the characteristic of improving the cathode performance of the solid oxide fuel cells.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

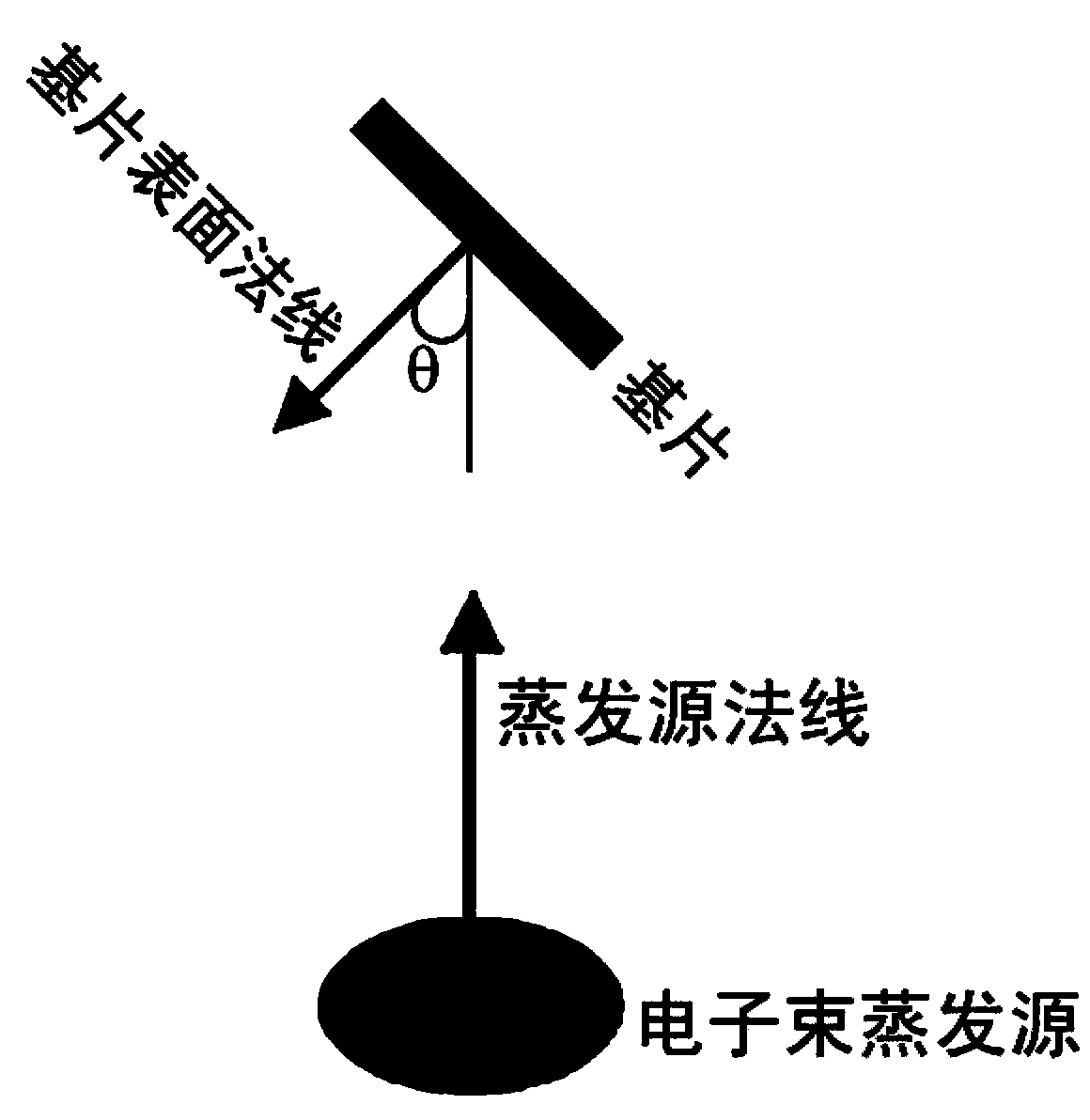

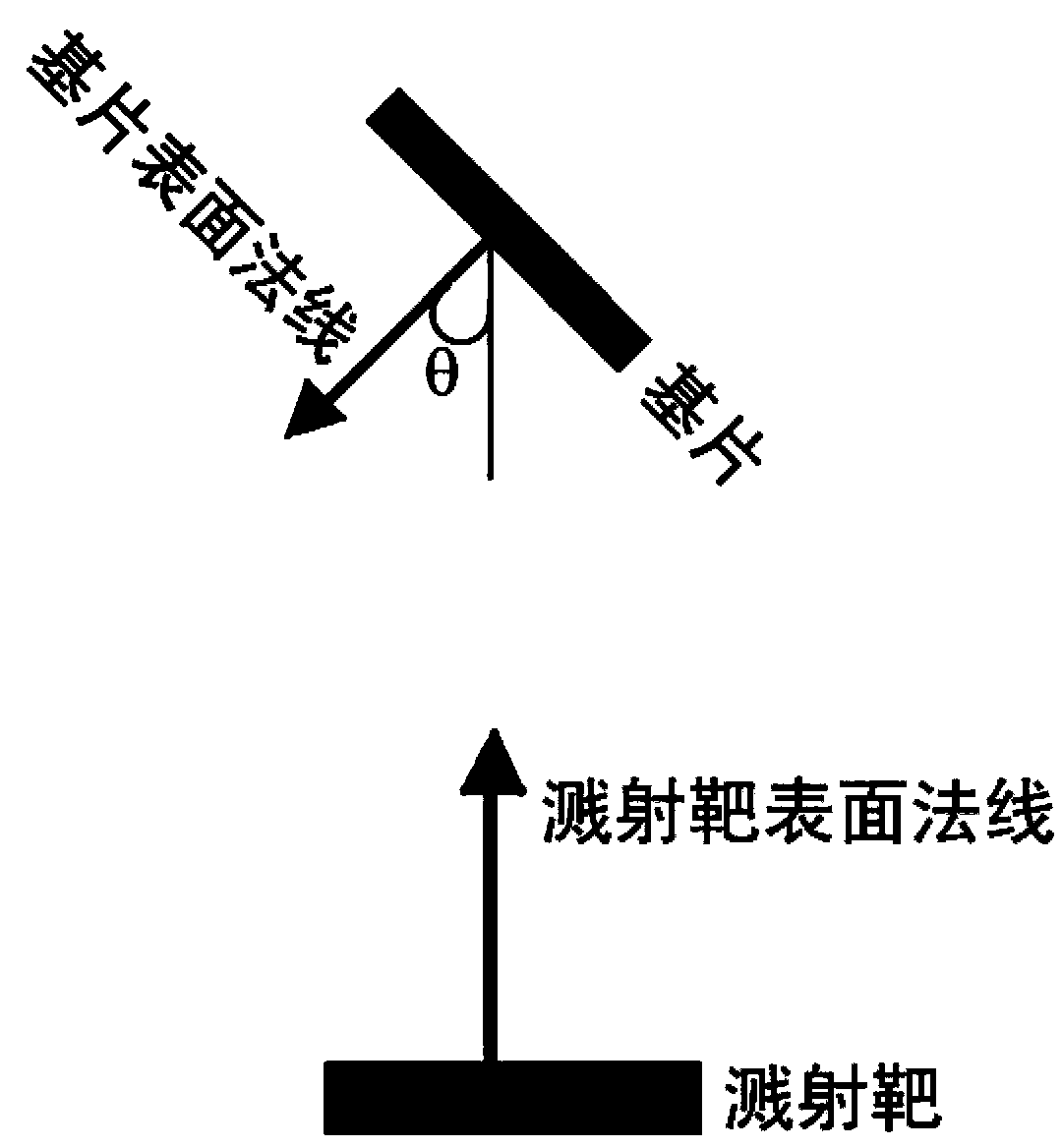

Thin film deposition preparation method and preparation method of nano-fiber structure flexible buffer layer

InactiveCN103409723AImprove performanceImprove flexibilityBlade accessoriesVacuum evaporation coatingNanofiberHeat stress

The invention provides a thin film deposition preparation method and a preparation method of a nano-fiber structure flexible buffer layer, and belongs to the technical field of materials. The thin film deposition preparation method comprises a temperature rise step and a deposition step. The thin film deposition preparation method is characterized in that in the deposition step, an included angle between the normal line of a deposition source and the normal line of the surface of a substrate ranges from 30 to 80 degrees. The preparation method provided by the invention has the advantages that a heat stress release mechanism with excellent performance is provided, and a nano-fiber structure Al2O3 flexible buffer layer thin film prepared by the preparation method has excellent flexibility and insulation property and low oxygen diffusion coefficient.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

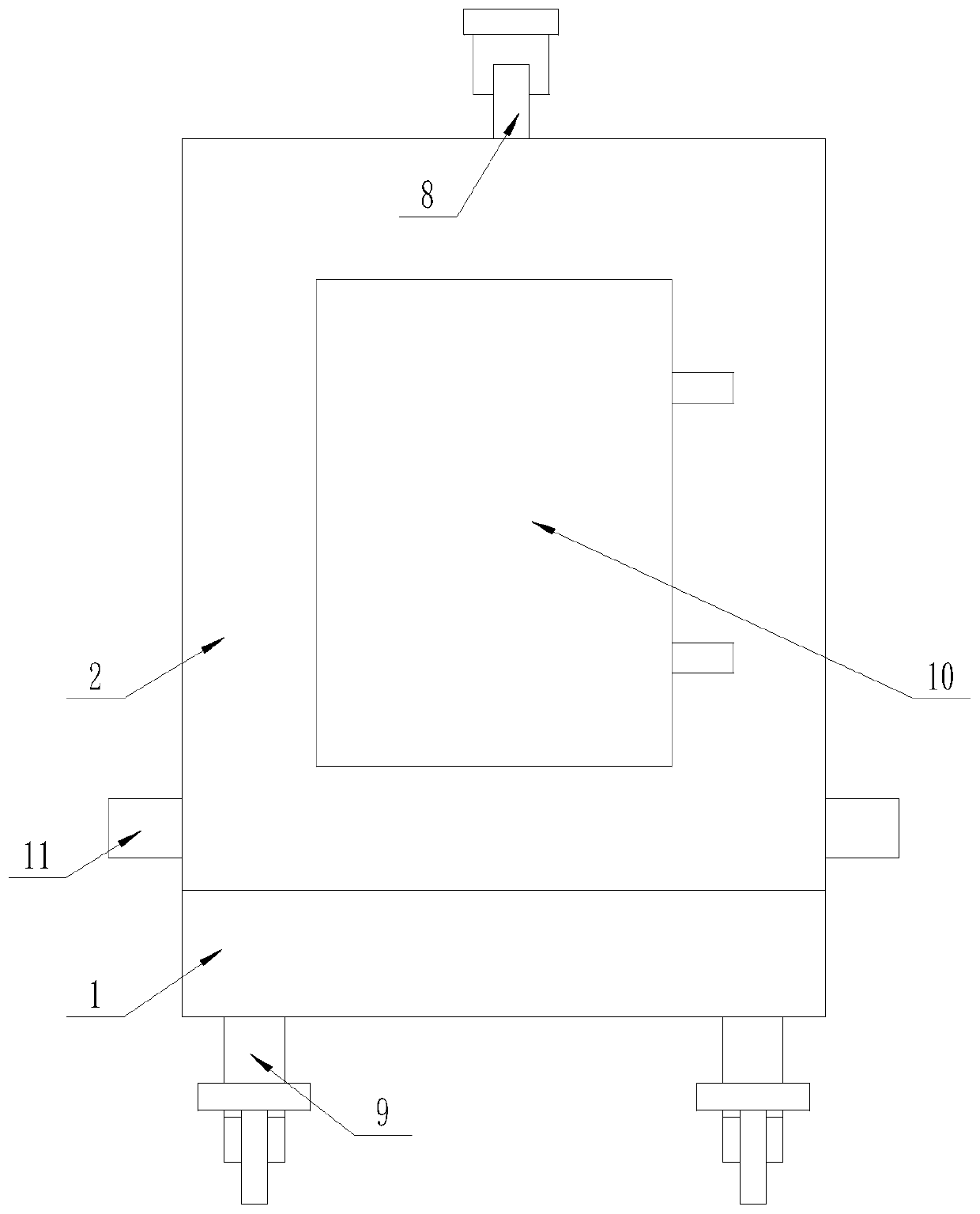

Concrete oxygen diffusion coefficient testing device

ActiveCN107085091AEasy to testEasy to knowMaterial testing goodsEngineeringOxygen diffusion coefficient

The invention discloses a concrete oxygen diffusion coefficient testing device which comprises a rectangular frame. A rectangular box body is installed on the upper wall face of the rectangular frame, the inside of the rectangular box body is of a hollow mechanism, the outside of the rectangular box body is a rectangular mechanism, a pair of partition plates is installed in the rectangular box body, a strip-shaped through hole is formed in the side wall face of the rectangular box body and located between the partition plates, a round through hole I is formed in the upper wall face of the rectangular box body, an air inlet pipe is installed in the round through hole I, and a round through hole IV is formed in the lower wall face of the rectangular box body. The concrete oxygen diffusion coefficient testing device brings convenience to people for concrete oxygen diffusion coefficient testing, is simple and convenient, makes the people conveniently, simply and clearly know the concrete quality and is high in practicability.

Owner:LANZHOU JIAOTONG UNIV

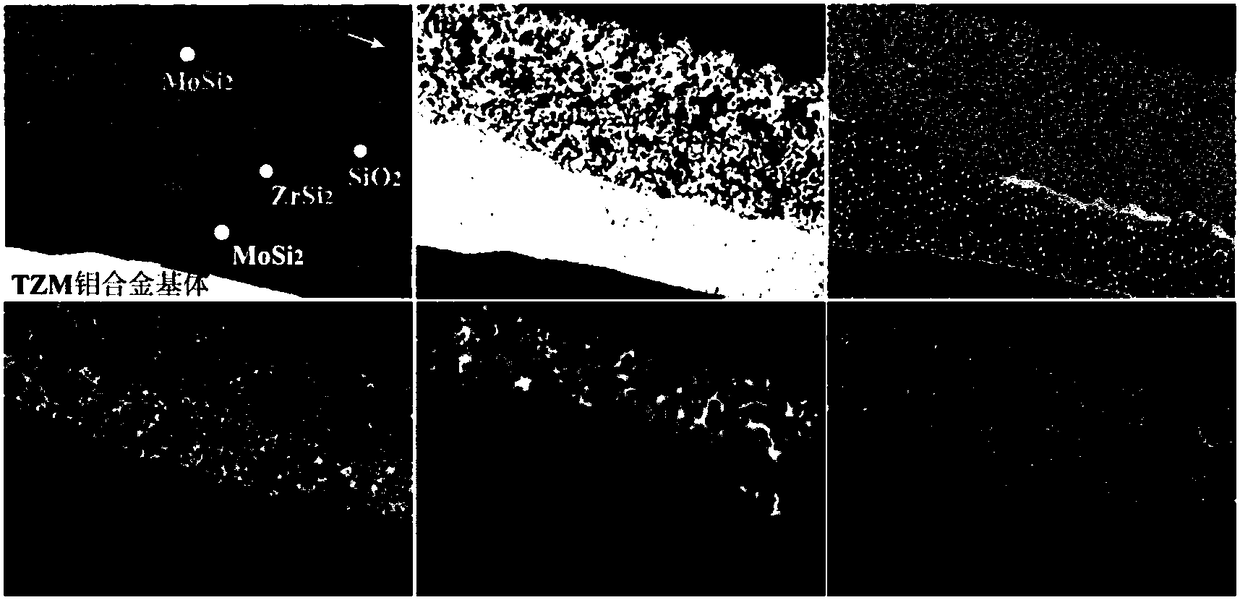

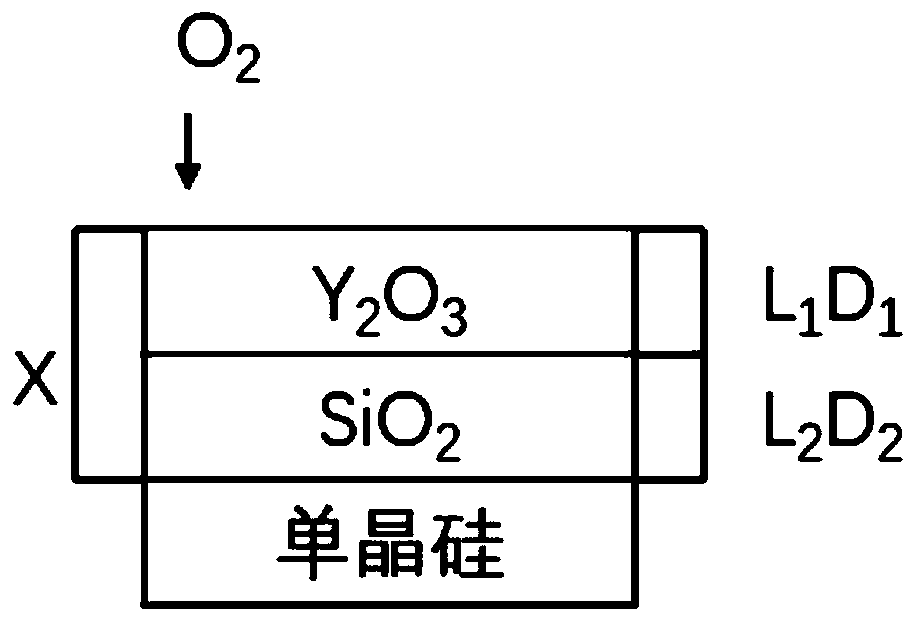

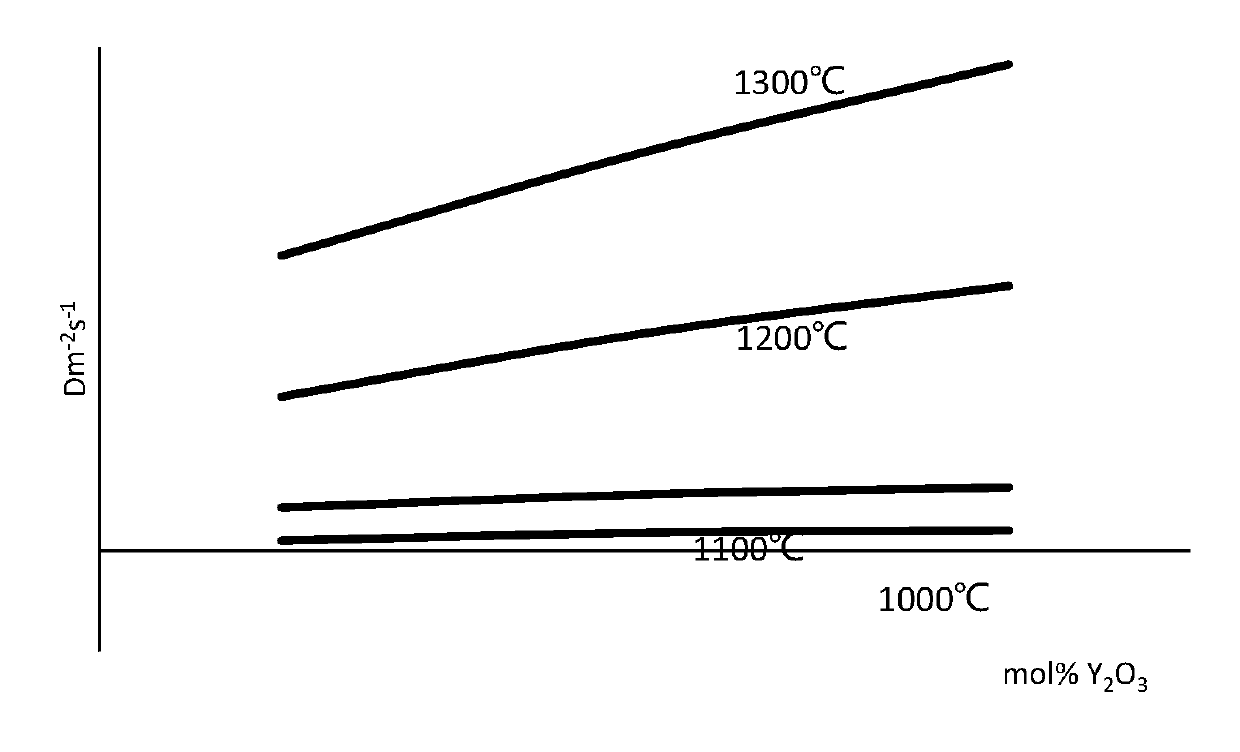

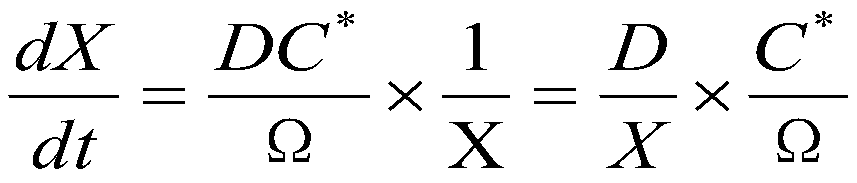

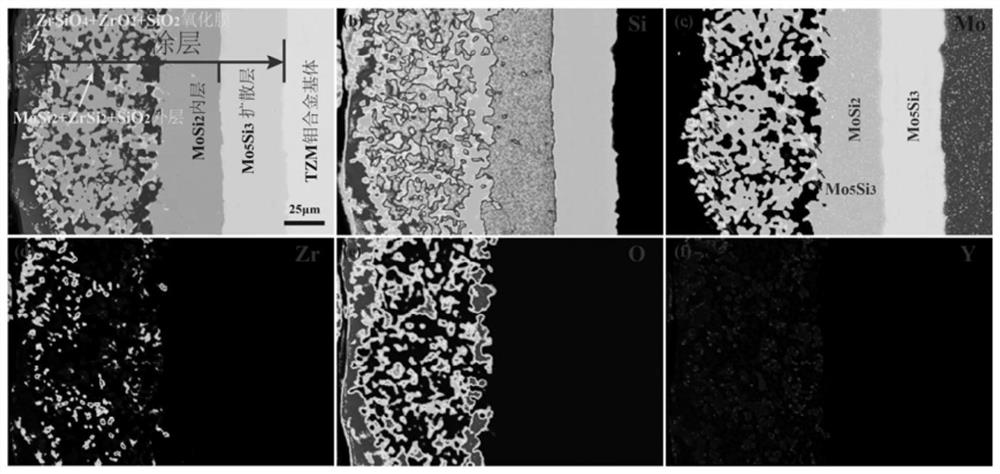

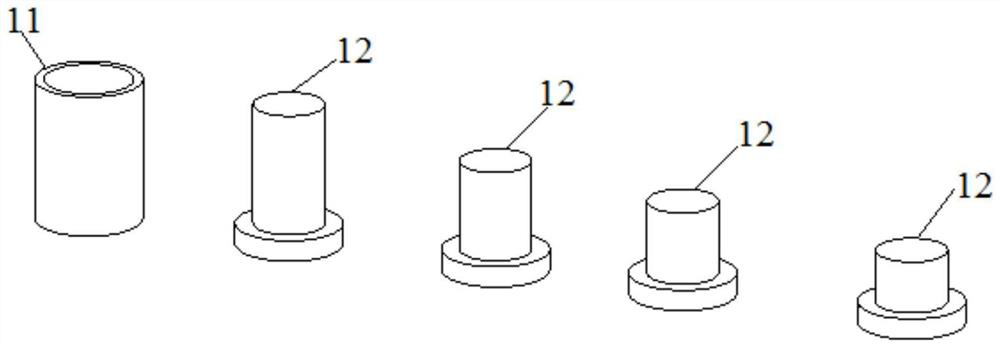

Preparation method of molybdenum disilicide series oxygen diffusion coefficient verifying diaphragm, and method used for calculating film oxygen diffusion coefficient

InactiveCN110282629AExtended service lifeIncrease the use temperatureMetal silicidesHeating element materialsCooking & bakingPhysical chemistry

The invention provides a preparation method of a molybdenum disilicide series oxygen diffusion coefficient verifying diaphragm, and method used for calculating film oxygen diffusion coefficient. The preparation method comprises following steps: SiO2 base solution preparation, oxidation corrosion resistant doped solution preparation, mixing of a working mother liquor B into a working mother liquor A at different ratios, silicon chip washing, silicon chip doping film preparation, and baking of generated amorphous film in a high temperature tubular furnace. The preparation method is capable of prolonging the service life of MoSi2 heating elements, increasing using temperature, and realizing accurate verifying of oxygen diffusion coefficient, so that the industrial value is high, and the application prospect is promising; and at the same time, the method used for calculating film oxygen diffusion coefficient is simple, convenient, and accurate, and possesses significant meaning in study on high temperature corrosion mechanisms.

Owner:GUIZHOU ACADEMY OF TESTING & ANALYSIS

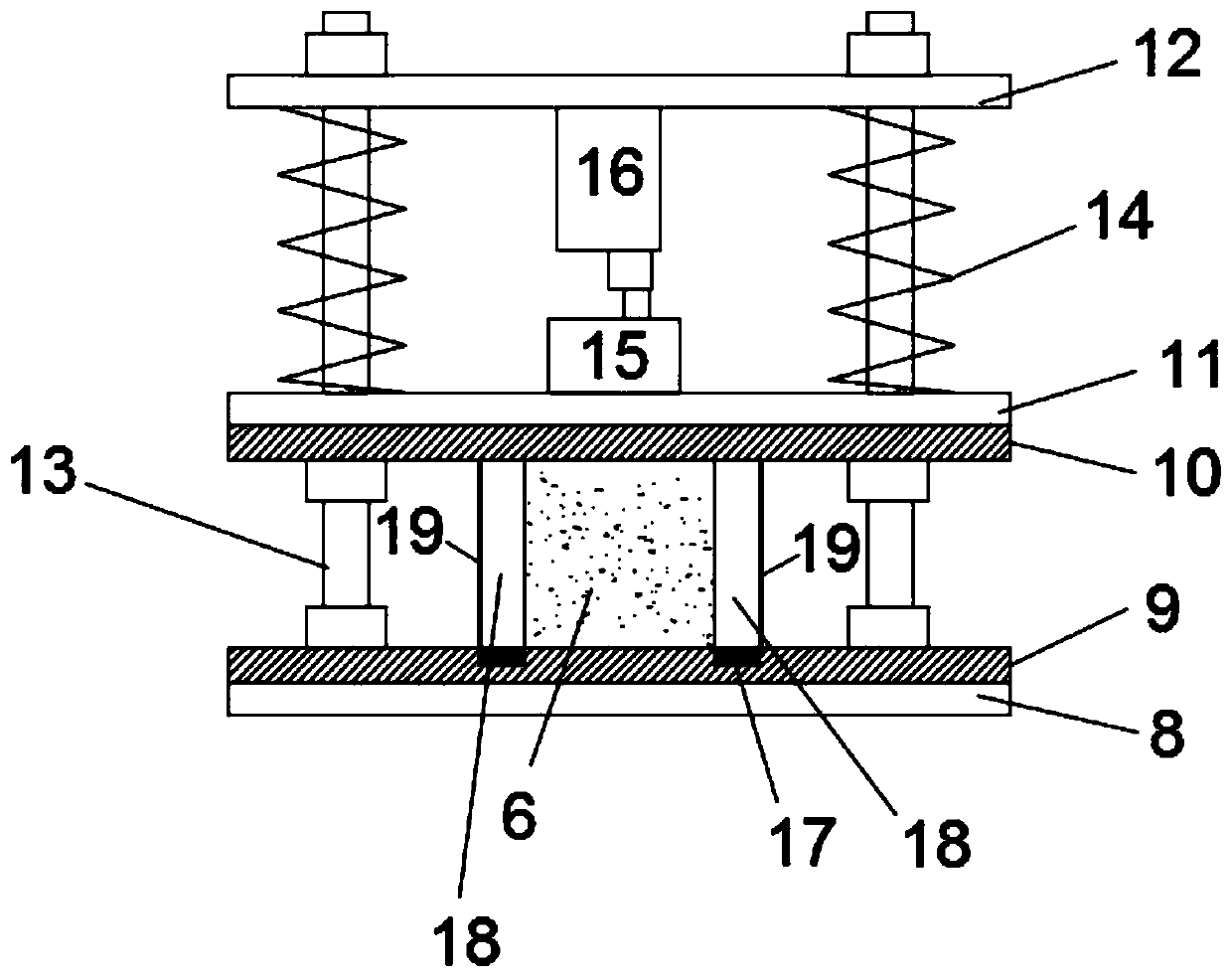

Device for measuring oxygen diffusion coefficients in concrete with different saturations under action of continuous tension and compression

ActiveCN111504876AEasy to calculateEasy to measureGas dispersion analysisPermeability/surface area analysisEngineeringRubber mat

The invention relates to the field of concrete oxygen diffusion coefficient determination devices, in particular to a device for measuring the oxygen diffusion coefficients in concrete with differentsaturations under the action of continuous tension and compression. The device comprises a to-be-tested piece, an oxygen diffusion device and a continuous tension and compression load device, whereinthe oxygen diffusion device is formed by connecting a central circle gas diffusion chamber and an outer circle gas diffusion chamber in a concentric circle structure, and the oxygen diffusion device is tightly attached to the to-be-tested piece through a rubber pad to form a closed space, and the continuous tension and compression load device is arranged in the vertical direction of the gas diffusion surface, so that the oxygen diffusion coefficient at any position of the test piece can be detected, and the detected oxygen diffusion coefficient is the oxygen diffusion coefficient under the continuous load and is closer to the actual engineering operation.

Owner:JIANGSU UNIV OF SCI & TECH

Carbon/carbon composite material ultrahigh temperature oxidation resistant coating and preparation method thereof

The invention discloses a carbon / carbon composite material ultrahigh temperature oxidation resistant coating. The coating comprises the following components, by volume, 40-60% of ZrB2, 15-25% of SiC, 15-20% of TaB2 and 10-15% of Sc2O3. In addition, the invention also provides a preparation method of the coating. According to the invention, TaB2 and Sc2O3 are added to make the melting point of an external layer oxidation product borosilicate glass be risen, the viscosity of the borosilicate glass be risen, the evaporation rate of the borosilicate glass be reduced, the oxygen dispersion coefficient of the borosilicate glass be reduced, an internal layer oxidation product ZrO2 phase be stable, the melting point of ZrO2 be risen, and the oxygen diffusion coefficient of ZrO2 be reduced, so thecoating can satisfy requirements of the ultrahigh temperature oxidation resistance of a carbon / carbon composite material, the coating can be sintered without applying a pressure through adding TaB2 and Sc2O3, the coating has the advantages of high combination strength, compactness, and good ultrahigh temperature mechanical property, and the preparation process has no damages to matrixes.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

A kind of nanometer multi-layer coating and its preparation method and the cutter with nanometer multi-layer coating on the surface

ActiveCN111962036BImprove efficiencySimple processVacuum evaporation coatingSputtering coatingHeat stabilityOxygen diffusion coefficient

The invention provides a nanometer multi-layer coating, a preparation method thereof, and a tool whose surface is coated with the nanometer multi-layer coating, belonging to the technical field of protective coatings. The nano-multilayer coating provided by the present invention includes (AlCrTiZrMo)N nano-layers and Cr layers alternately stacked on the surface of the substrate. 2 O 3 nanolayers. In the nano-multilayer coating provided by the present invention, (AlCrTiZrMo)N nano-layer and Cr 2 O 3 Coherent boundaries are formed between the nano-layers, which hinders the movement of dislocations, and the hardness of the nano-multilayer coating is high; because the modulation layer is Cr with low oxygen diffusion coefficient 2 O 3 The nano-layer makes the thermal stability of the nano-multilayer coating better than that of the (AlCrTiZrMo)N single-layer coating. The nano-multilayer coating provided by the invention has both high hardness and high thermal stability, can make up for the deficiencies in the use of traditional tool coatings, broaden the research scope of tool coatings, and meet the performance requirements of high-speed cutting and dry cutting.

Owner:上海工具厂有限公司 +1

A device for testing the oxygen diffusion coefficient of concrete

Owner:LANZHOU JIAOTONG UNIV

Solid oxide fuel cell structure and preparation method thereof

InactiveCN102347495BImprove adsorption capacityImprove cathode performanceCell electrodesSolid electrolyte fuel cellsSurface exchange coefficientFuel cells

The invention belongs to the field of solid oxide fuel cells, in particular relates to a solid oxide fuel cell structure and a preparation method thereof. The cell structure comprises a cell cathode layer, an electrolyte layer and a cell anode layer in sequence from top to bottom, wherein the cell cathode layer is divided into a PrBaCo2O5 layer and an LSM (La0.8S0.2MnO3) layer from top to bottom; the electrolyte layer is YSZ (Yttria Stabilized Zirconia); the cell anode layer is Ni-YSZ; and the thickness of the PrBaCo2O5 layer is 2-4 microns. Because PrBaCo2O5 has higher catalytic performance, oxygen diffusion coefficients, surface exchange coefficients and oxygen ion migration capability, the oxygen adsorbing capability and oxygen dissociating capability of a cathode can be improved by adopting a PrBaCo2O5-LSM / YSZ / Ni-YSZ structure and material system; and the solid oxide fuel cell structure has the characteristic of improving the cathode performance of the solid oxide fuel cells.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

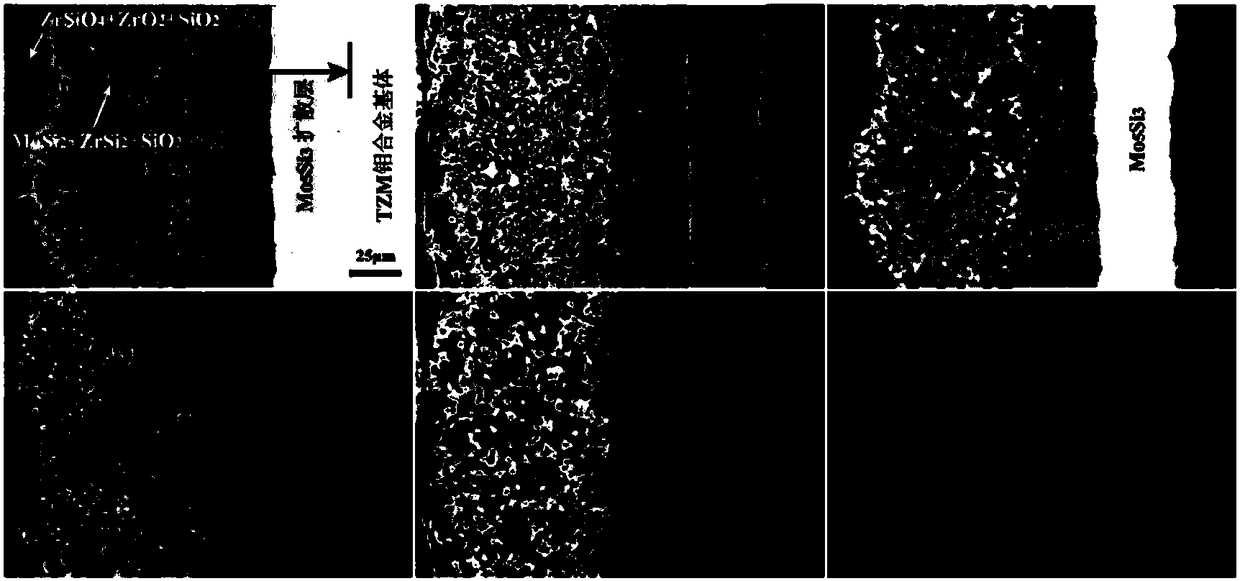

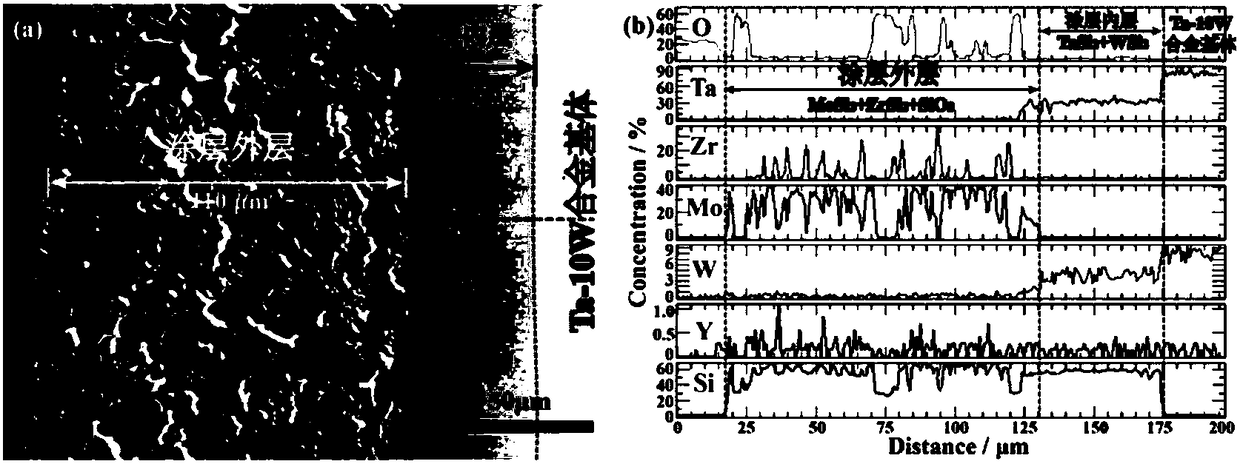

A kind of refractory metal high temperature anti-oxidation si-mo-ysz coating and its preparation method

ActiveCN108585897BHigh viscosityReduce evaporation rateHeat inorganic powder coatingThermal dilatationMetallic materials

The invention relates to a refractory metal high-temperature antioxidant Si-Mo-YSZ coating and a preparation method thereof. The refractory metal high-temperature antioxidant Si-Mo-YSZ coating is madefrom, by weight, 45-65% of Si, 25-40% of Mo, 2-15% of YSZ (yttria-stabilized zirconia), and 2-8% of additives. Materials of coating are made into a slurry first; the slurry is applied to the surfaceof a refractory metal; the refractory metal is sintered at 1370-1530 DEG C for 20-90 min. since the coating composition is reasonably made in conjunction with thermal expansion coefficient of a refractory metal base, the coating, during use, can quickly form a ZrSiO4-ZrO2-SiO2 composite oxide film, effectively reducing oxygen diffusion coefficient of the coating, and implementing long-term antioxidant use of various refractory metals at the temperature of 1700 DEG C and above. The preparation method is simple and low in cost; the coating has good thermal matching with a base; high-temperatureoxidation resistance of refractory metals can be effectively improved.

Owner:CENT SOUTH UNIV

Method for measuring relative gas diffusion coefficient of soil under different soil water potentials and volume weights

PendingCN114354450AEasy dischargeWeighing by removing componentEarth material testingGreenhouseSoil core

The invention discloses a method for measuring soil relative gas diffusion coefficients under different soil water potentials and volume weights, and belongs to the technical field of soil water potential and relative gas diffusion coefficient measurement. The method comprises the following steps: respectively measuring water potentials corresponding to soil cores with different preset volume weights by using a specific soil water potential measuring device, and respectively measuring oxygen diffusion coefficients corresponding to the soil cores with different preset volume weights by using a specific soil relative gas diffusion coefficient measuring device; and thus, the soil water potential and the soil relative gas diffusion coefficient value corresponding to each soil core with the preset volume weight are obtained. According to the method, the field soil water potential and the soil relative gas diffusion coefficient corresponding to different soil bulk density states can be simulated under the indoor condition, the soil air permeability can be measured, and emission of greenhouse gas N2O and the like can be predicted.

Owner:LANZHOU UNIVERSITY

A method for measuring the diffusion coefficient of dissolved oxygen in biofilm

ActiveCN103969302BCalculation of dissolved oxygen diffusion coefficientShort timeMaterial electrochemical variablesMathematical modelOxygen

The invention discloses a device and method for measuring the diffusion coefficient of dissolved oxygen in a biological membrane. The device comprises a gas delivery device, an intake gas humidification bottle, a biological membrane measuring chamber and a dissolved oxygen microelectrode system. The method for measuring the diffusion coefficient of the dissolved oxygen by utilizing the device comprises the following steps: placing a to-be-measured biological membrane sample into the biological membrane measuring chamber, and introducing nitrogen to reduce the concentration of oxygen in the system to be the minimum; then changing intake gas into oxygen, and meanwhile using a dissolved oxygen microelectrode to record the curve about time-dependent change of the dissolved oxygen in the biological membrane; repeating the test in different positions and different depths of the biological membrane, so as to obtain multiple pieces of sample data; simulating the process through a mathematical model and fitting model data and data measured in the test, and calculating the diffusion coefficient of the dissolved oxygen. According to the invention, the time consumed is short, and precise chemical analysis is not required, so that the measuring result is accurate, the repeatability is good, and the system error is very small.

Owner:嘉兴华吉环保科技有限公司

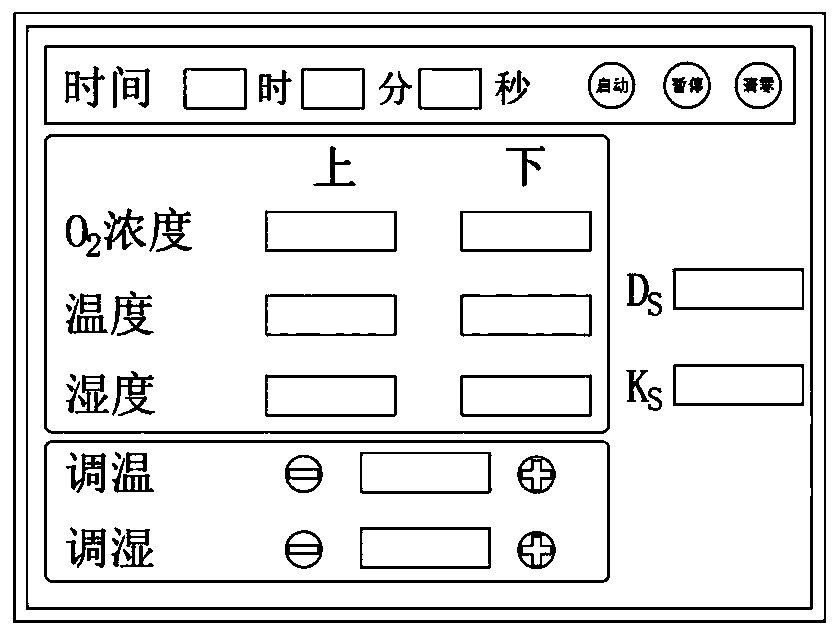

Measurement device and measurement method for measuring oxygen diffusion coefficient and consumption coefficient in bituminous mixture

PendingCN110865009AGuaranteed accuracyUniform temperature distributionPermeability/surface area analysisMeasurement deviceTest sample

The invention discloses a measurement device and a measurement method for measuring an oxygen diffusion coefficient and consumption coefficient in a bituminous mixture, and belongs to the technical field of performance measurement of a road construction material. The measurement device particularly comprises a test box, a heat preservation box and a control box connected with the test box and theheat preservation box; the test box is arranged in the heat preservation box; the test box comprises an upper test cavity, a middle test sample cavity and a lower test cavity; the middle test sample cavity is used for placing a to-be-measured compacted bituminous mixture; the upper test cavity is communicated with the lower test cavity through the middle test sample cavity; oxygen concentration sensors are arranged on both the upper test cavity and the lower test cavity; and the oxygen concentration sensors are used for detecting concentration of oxygen in gas in the upper test cavity or the lower test cavity. The oxygen diffusion coefficient and the oxygen consumption coefficient in the compacted bituminous mixture are measured by utilizing the device disclosed by the invention; a simulated environment of the device is close to a real pavement environment; accuracy of measured data can be ensured; reliable reference can be provided for evaluating ageing sensitivity of the bituminous mixture; and the measurement device and the measurement method are simple in experiment operation process.

Owner:CHANGAN UNIV

Composite coating and application thereof in carbon/carbon composite material

ActiveCN103360124BHigh temperature resistanceGood heat matchingLiquid/solution decomposition chemical coatingCarbon compositesChemical reaction

The invention relates to a composite coating and application thereof in a carbon / carbon composite material, and belongs to the technical field of manufacturing of an anti-oxidizing carbon / carbon composite material. An SiC coating which is similar to a coefficient of thermal expansion of the carbon / carbon composite material is adopted as a base transition layer; the SiC coating is prepared by adopting an in situ chemical reaction method; gradient transition of Si-C is achieved on carbon / carbon composite material matrix; the binding strength of the carbon / carbon matrix and the SiC coating is enhanced; the difference of thermal expansion between the carbon / carbon matrix and an M-Si-O coating is effectively relieved; the M-Si-O coating with high temperature resistance grade, low oxygen diffusion coefficient and high thermal emissivity is selected as an outer coating; the M-Si-O coating is prepared by sol dipping-high temperature sintering treatment.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com