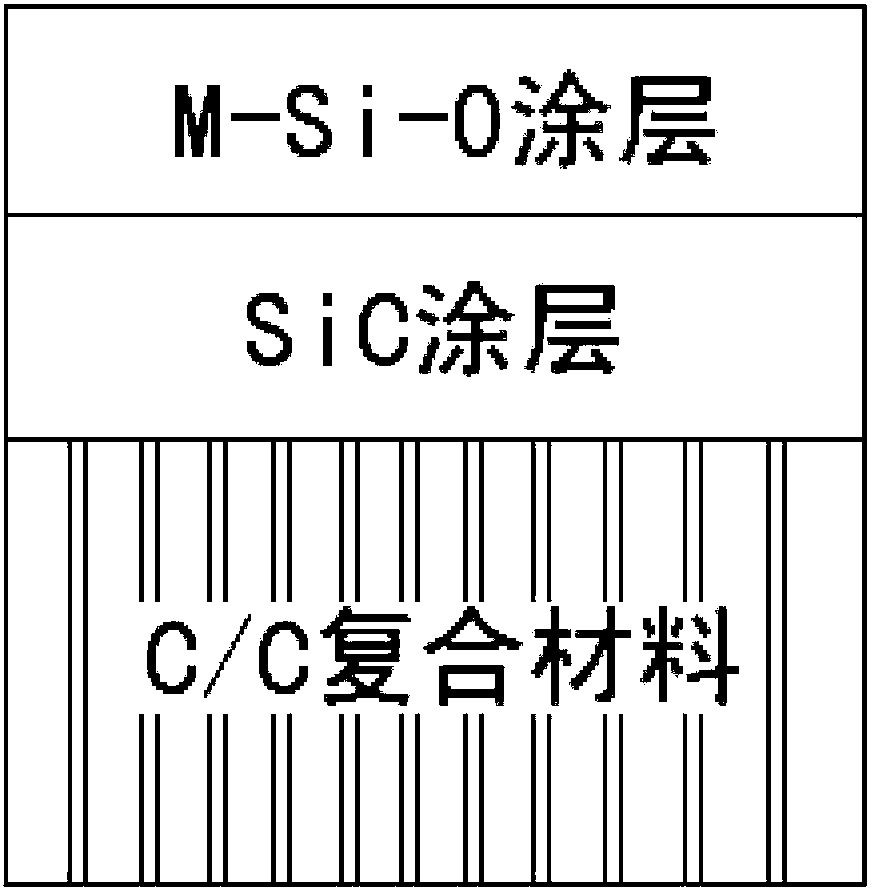

Composite coating and application thereof in carbon/carbon composite material

A carbon composite material and composite coating technology, applied in the field of anti-oxidation carbon/carbon composite material manufacturing, can solve the problems of low temperature resistance grade of anti-oxidation coating and poor matrix interface matching, so as to reduce thermal expansion differences, The effect of high temperature resistance grade and high melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) SiC, Si, Al with a purity of 95% and a particle size of 200 mesh 2 o 3 Put 500g of powder C and 500g each in an oven at 150°C for 2 hours and take it out, according to the weight ratio of the ingredients SiC:Si:Al 2 o 3 : C=4:4:1:1 Weigh the raw materials with a total weight of 1000g and put them into a ball mill tank, mix them at a speed of 30 rpm for 10 hours, then take them out for later use.

[0029] 2) After cleaning and drying the carbon / carbon composite material sample, place it in a graphite crucible, and embed it with the mixed reaction powder around it. Before the sample was embedded, the graphite crucible was dried at 150°C / 2 hours, and carbon felt was laid around the crucible. Subsequently, the graphite crucible was put into a high-temperature furnace, and after the furnace was vacuumed for 20 minutes, it was protected by argon gas, and the temperature was raised to 1800 ° C for 4 hours. After cooling with the furnace, it was taken out, cleaned with al...

Embodiment 2

[0038] Same as Example 1, the difference is that the sol prepared in step 3) is Y-Si-O sol, specifically: take 0.1mol yttrium nitrate and dissolve it in 0.5mol deionized water, add 1mol absolute ethanol after it is completely dissolved, and Stir with a magnetic stirrer at room temperature for 30 minutes, then slowly add 0.1 mol tetraethyl orthosilicate dropwise under stirring conditions, continue stirring until the solution is clear and transparent, stop stirring, and age for 24 hours to obtain Y-Si-O sol; The sintering temperature in step 7) is 1800° C. to obtain a SiC / Y-Si-O composite coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com