Thin film deposition preparation method and preparation method of nano-fiber structure flexible buffer layer

A thin film deposition and nanofiber technology, applied in the field of materials, can solve the problems of peeling off of protective coatings, large differences in thermal expansion coefficients, equipment damage, etc., and achieve the effects of good flexibility and insulation, small oxygen diffusion coefficient, and good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

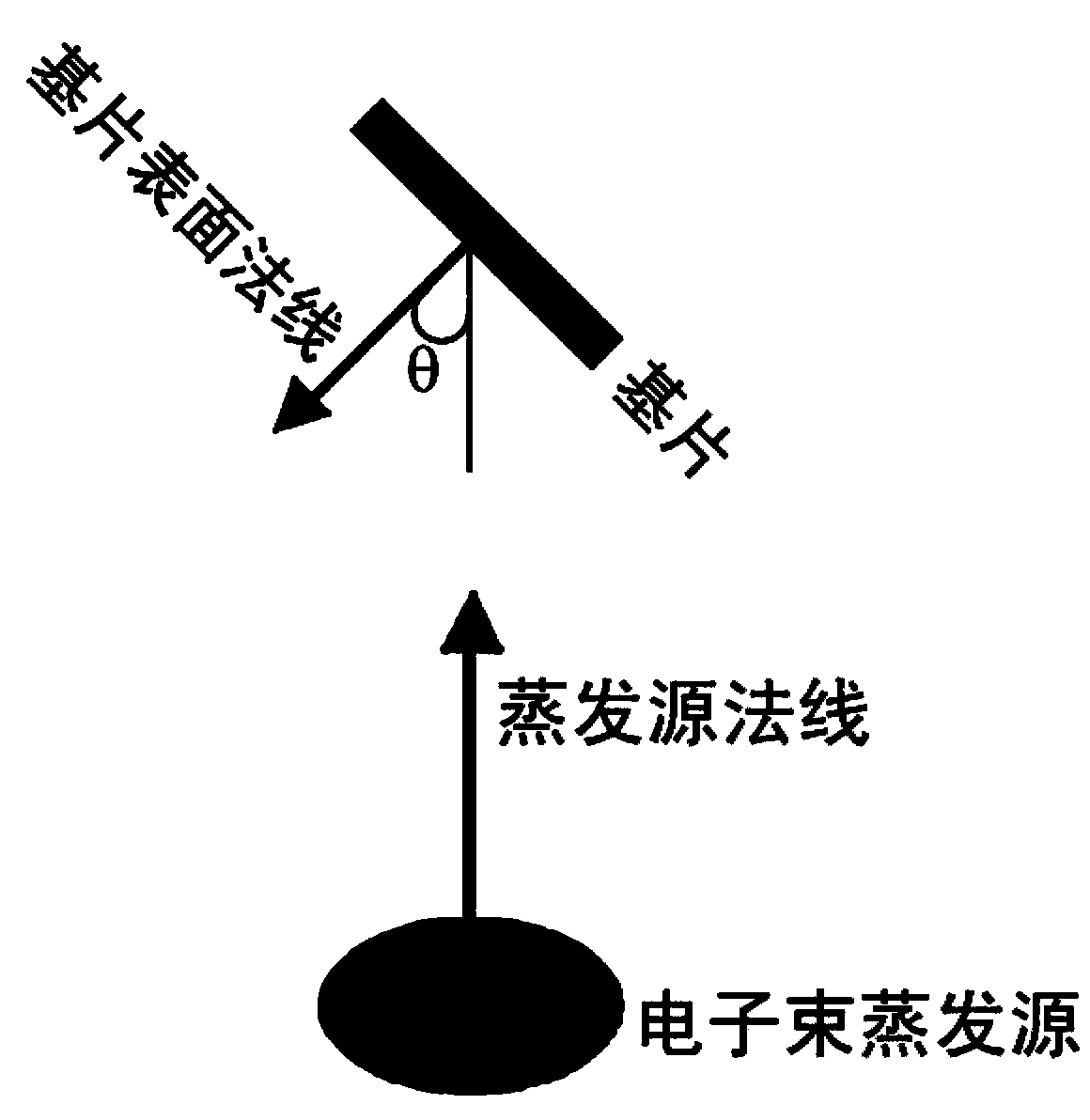

[0019] Example 1 Electron beam evaporation to prepare obliquely arranged nanofibrous structure Al 2 o 3 film

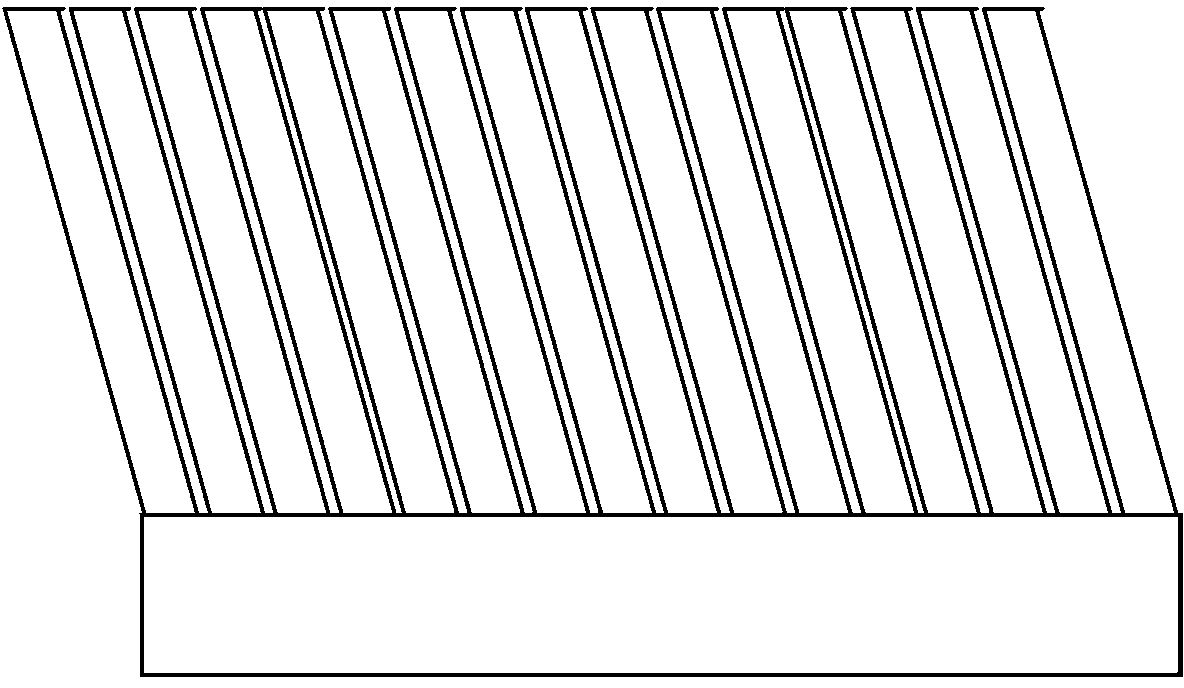

[0020] Al was deposited by electron beam evaporation 2 o 3 film, the normal of the substrate surface and the normal of the evaporation source are at an angle of 45°, and the temperature of the substrate is 200°C, the prepared Al 2 o 3 The thickness of the film is 3 microns, and its cross-sectional appearance is as attached Figure 4 As shown, it presents a typical structure characteristic of obliquely arranged nanofibers.

Embodiment 2

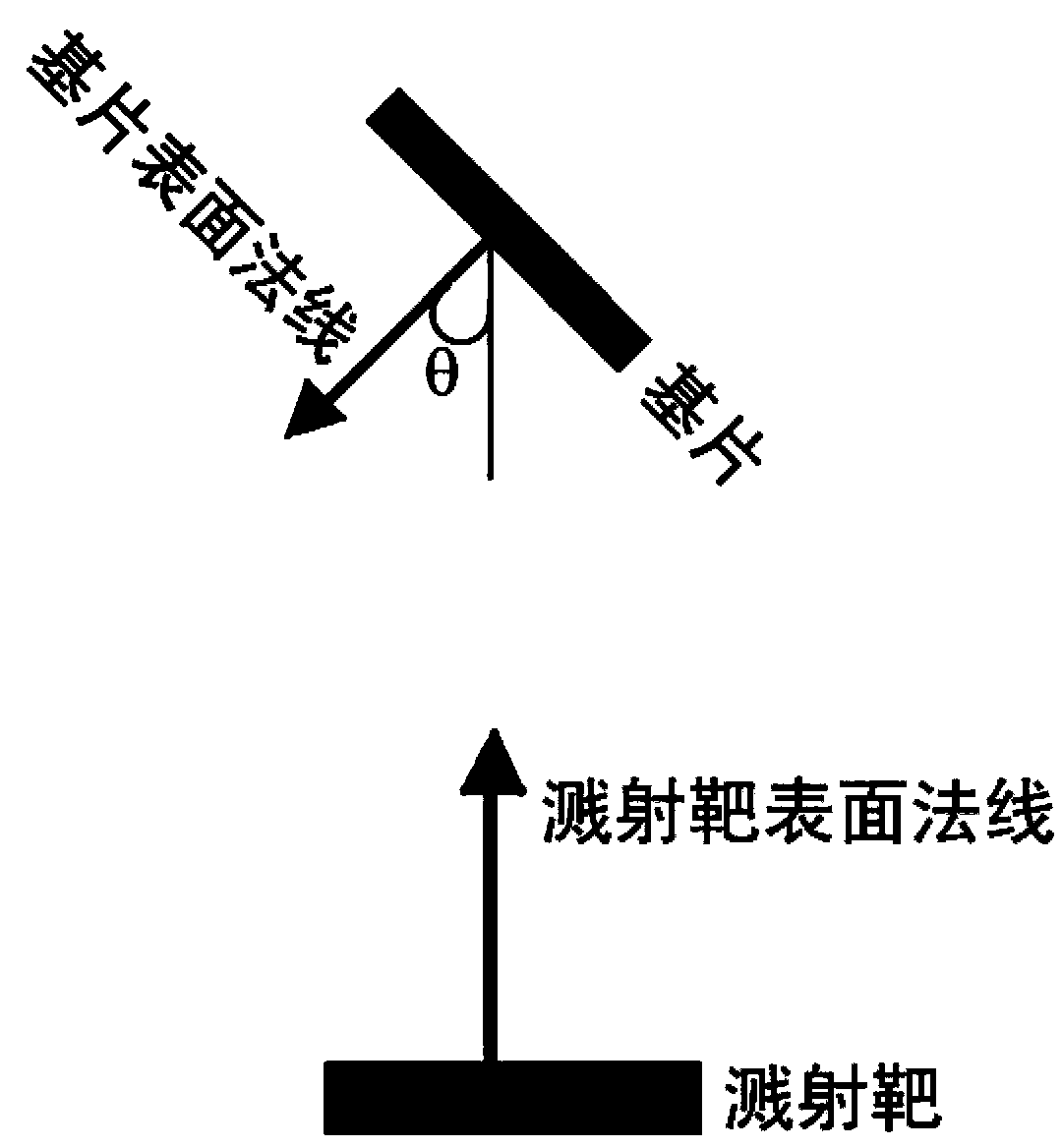

[0021] Example 2 Electron beam evaporation to prepare obliquely aligned nanofibrous structure Al 2 o 3 flexible cushioning layer

[0022] First use the process conditions as in Example 1 to prepare a tilted nanofiber structure Al with a thickness of about 2.5 microns. 2 o 3 thin film, then adjust the normal of the substrate surface and the normal of the evaporation source to an angle of 0°, and continue to deposit about 7.5 microns thick Al 2 o 3 thin film so that the entire Al 2 o 3 The film thickness reaches about 10 microns. Prepared Al 2 o 3 The cross-sectional morphology of the film is as attached Figure 5 Shown, visible: the entire Al 2 o 3 The film can be divided into two parts, the first part is about 2.5 microns thick with nanofibrous structure Al 2 o 3 film, which acts as a flexible buffer layer throughout the film to relieve film thermal stress during thermal shock; the second part is about 7.5 microns thick Al 2 o 3 Continuous film, the film structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com