Method for determining oxygen diffusion coefficient in cement-based material and test device

A technology of cement-based materials and test devices, applied in measuring devices, analytical materials, diffusion analysis, etc., can solve the problems of low concrete porosity and small gas diffusion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

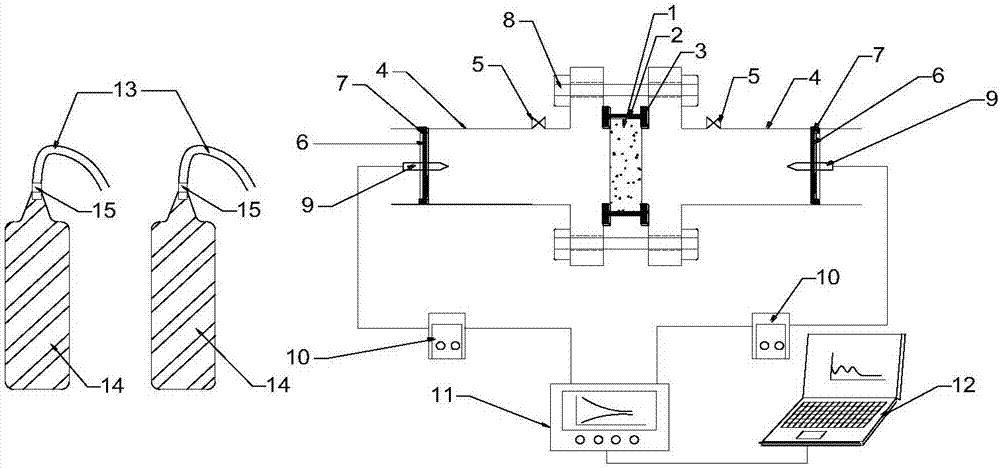

[0058] The present invention will be further explained below in conjunction with the drawings

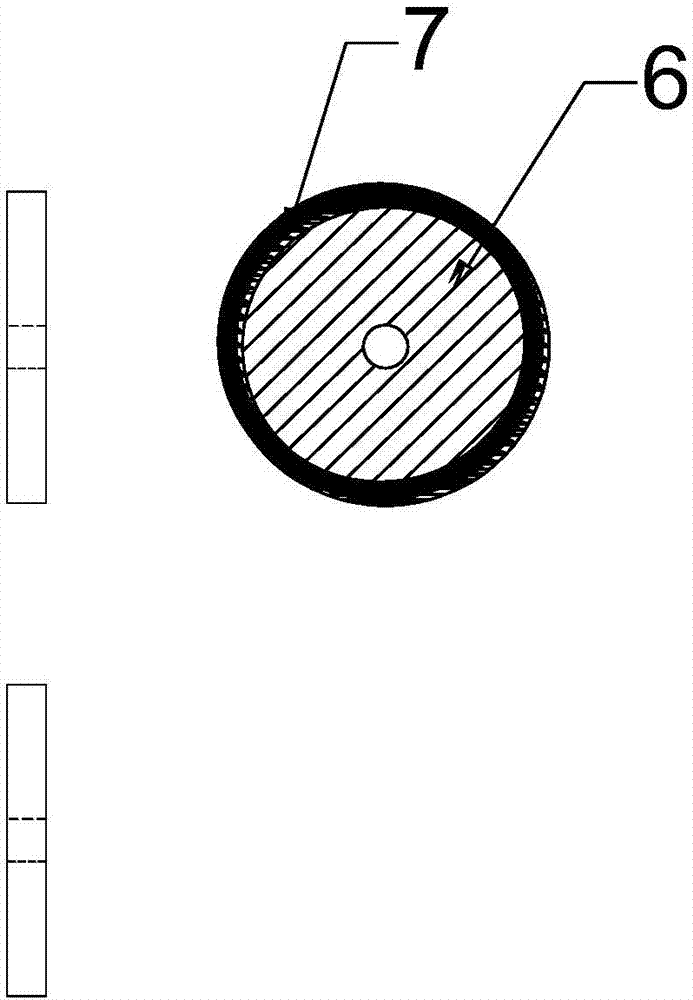

[0059] Reference Figure 1 ~ Figure 4 , A method for determining the diffusion coefficient of oxygen in cement-based materials, including the following steps:

[0060] 1) Preparation of cement-based materials to be tested

[0061] Pouring and forming the cement-based material specimen to be tested, cutting the measured cement-based material into a cylinder of a certain thickness, and coating the side of the specimen (non-oxygen diffusion surface) with epoxy resin to isolate the influence of the external atmosphere;

[0062] 2) Connection of the overall device

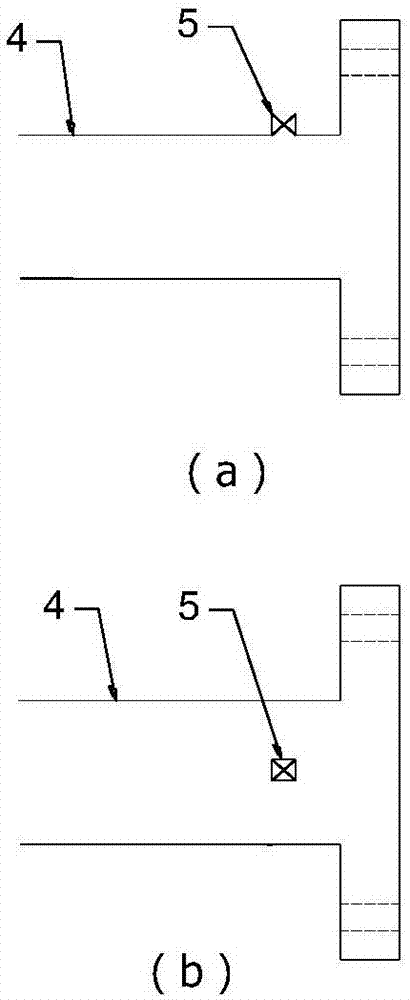

[0063] Put the rubber sealing gasket on the test piece obtained in 1) and connect the two gas chambers with stud bolts to form a sealed whole. The end surface of the test piece is the oxygen diffusion surface, and a little petroleum jelly is applied to the contact position to increase the tightness; The inlet valve on the upper part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com