A kind of refractory metal high temperature anti-oxidation si-mo-ysz coating and its preparation method

A refractory metal, si-mo-ysz technology, applied in the field of high temperature anti-oxidation coating preparation, can solve the problem of low temperature protection of high temperature anti-oxidation coating, achieve high viscosity, reduce various defects, excellent ultra-high temperature resistance. The effect of oxidative properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

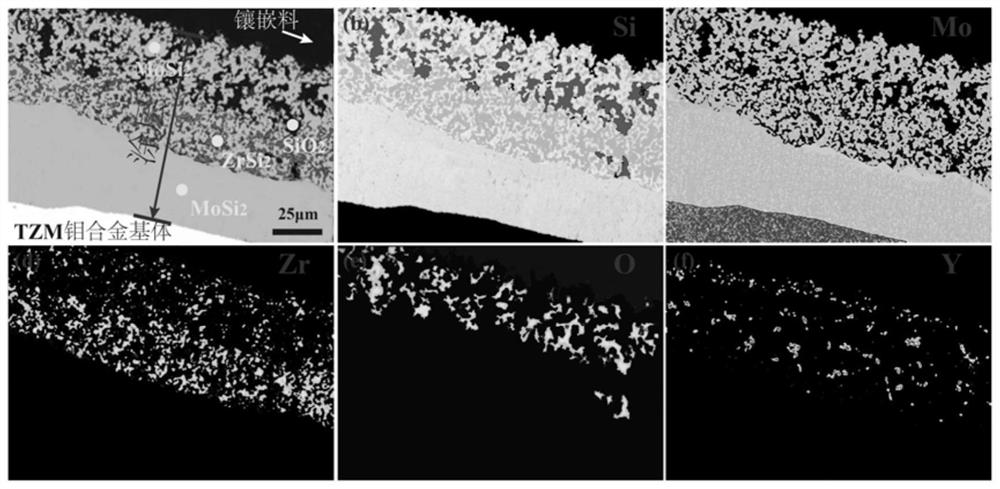

[0059] (1) Substrate pretreatment: select TZM molybdenum alloy as the substrate, polish with sandpaper until the surface is smooth and flat, then carry out pickling and alkali cleaning, then ultrasonically clean it in alcohol, and put it in a drying oven for drying.

[0060] (2) Slurry preparation: according to the mass fraction of 58.5% Si powder, 29% Mo powder and 9.5% YSZ powder, the average particle size of the three is 1μm, 3μm and 100nm; choose 0.1μm SiO 2 powder, 2μm NH 4 F powder and 5 μm PVB powder are used as additives, and the mass fraction ratios are 0.5%, 2% and 0.5% respectively; the purity of the six powders is not less than 99%. Put the prepared coating raw materials into a ball milling tank, the ball milling medium is ethanol, the ball to material ratio is 8:1, the rotating speed is 300r / min, and the ball milling time is 10h.

[0061] (3) Coating the slurry evenly and drying: The slurry described in (2) is uniformly coated on the surface of the molybdenum all...

Embodiment 2

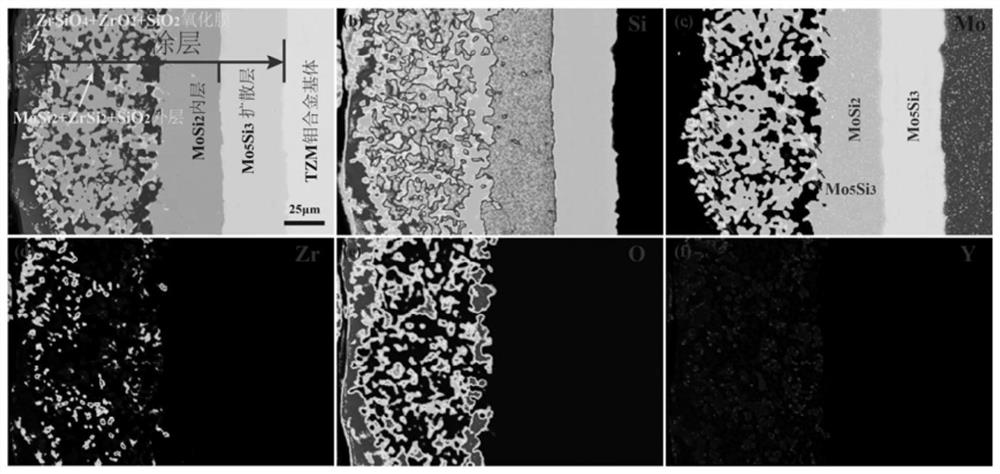

[0066] (1) Substrate pretreatment: select TZM molybdenum alloy as the substrate, polish with sandpaper until the surface is smooth and flat, then carry out pickling and alkali cleaning, then ultrasonically clean it in alcohol, and put it in a drying oven for drying.

[0067] (2) Slurry preparation: according to the mass fraction of 54% Si powder, 25% Mo powder and 15% YSZ powder, the average particle size of the three is 1μm, 3μm and 100nm; choose 0.1μm SiO 2 powder, 2μm NH 4 F powder is used as an additive, and the mass fraction ratio is 0.5% and 5.5% respectively; the purity of the five kinds of powders is not less than 99%. Put the prepared coating raw materials into a ball milling tank, the ball milling medium is ethanol, the ball to material ratio is 5:1, the rotating speed is 350r / min, and the ball milling time is 7h.

[0068] (3) Coating the slurry evenly and drying: the slurry described in (2) is evenly coated on the surface of the molybdenum alloy substrate after dry...

Embodiment 3

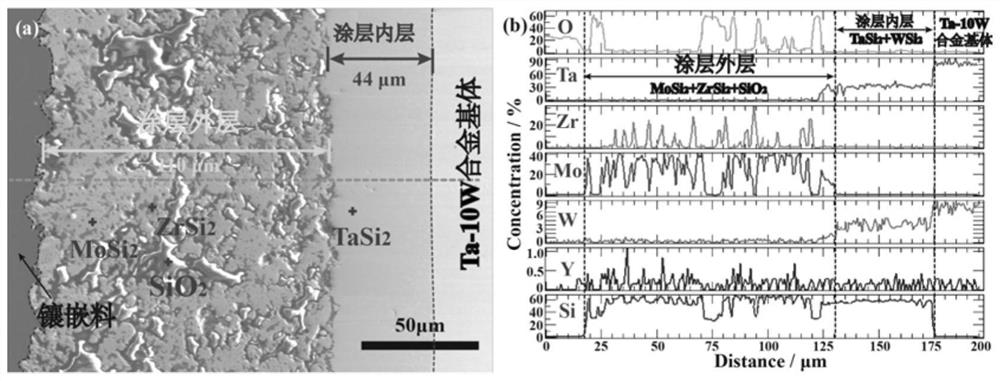

[0072] (1) Substrate pretreatment: select Ta-10W alloy as the substrate, polish it with sandpaper until the surface is smooth and flat, then carry out pickling and alkali cleaning treatment, then ultrasonically clean it in alcohol, and put it in a drying box to dry .

[0073] (2) Slurry preparation: according to the mass fraction of 56% Si powder, 30% Mo powder and 10% YSZ powder, the average particle size of the three is 1μm, 2μm and 200nm; choose 0.5μm SiO 2 Powder and 5 μm PVB powder are used as additives, and the mass fraction proportions are 3% and 1% respectively; the purity of the five kinds of powders is not less than 99%. Put the prepared coating raw materials into a ball milling tank, the ball milling medium is ethanol, the ball-to-material ratio is 10:1, the rotating speed is 400r / min, and the ball milling time is 6h.

[0074] (3) Evenly coat the slurry and dry: apply the slurry described in (2) evenly on the surface of the Ta-10W alloy substrate after drying in (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com