High-temperature thin film sensor with self-healing composite protective layer and preparation method thereof

A thin-film sensor and protective layer technology, applied in coatings, instruments, high-efficiency propulsion technology, etc., can solve performance degradation and other problems, and achieve the effects of enhanced oxidation resistance, low oxygen diffusion coefficient, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and implementation.

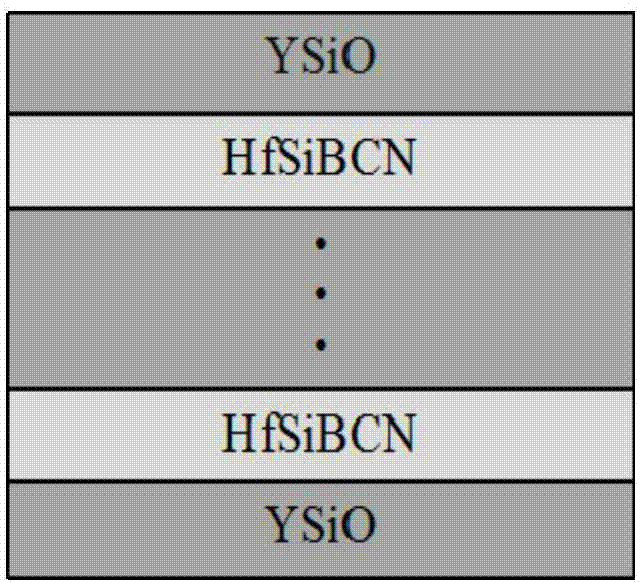

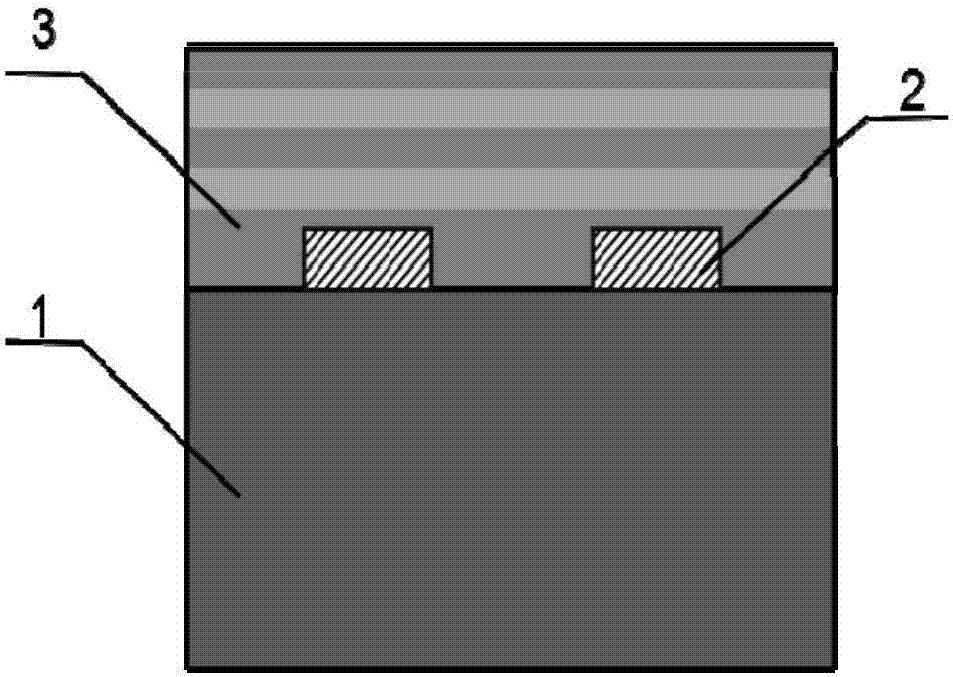

[0024] A kind of tungsten-rhenium thin-film thermocouple with self-healing composite protective layer is provided in this embodiment, and the Al 2 o 3 It consists of a ceramic substrate, a thin-film thermocouple positive and negative thermal electrodes, and a self-healing composite protective layer. The structure of the self-healing composite protective layer from bottom to top is: YSiO / HfSiBCN periodic multilayer film structure, wherein the period The number n=5, the lowermost layer and the uppermost layer of the protective layer are both YSiO low oxygen diffusion coefficient layers.

[0025] The specific preparation process of the above-mentioned tungsten-rhenium thin-film thermocouple with a self-healing composite protective layer is as follows:

[0026] Step 1, Al 2 o 3 Pretreatment of ceramic substrates: Al 2 o 3 The surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com