Epitaxial layer material stripping method based on 3D laminated mask substrate

An epitaxial layer and mask layer technology, applied in the field of optoelectronics, can solve the problems of slow grinding and polishing rate, unfavorable production efficiency, yield drop, etc., and achieve the effects of improving efficiency, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below through specific embodiments and accompanying drawings.

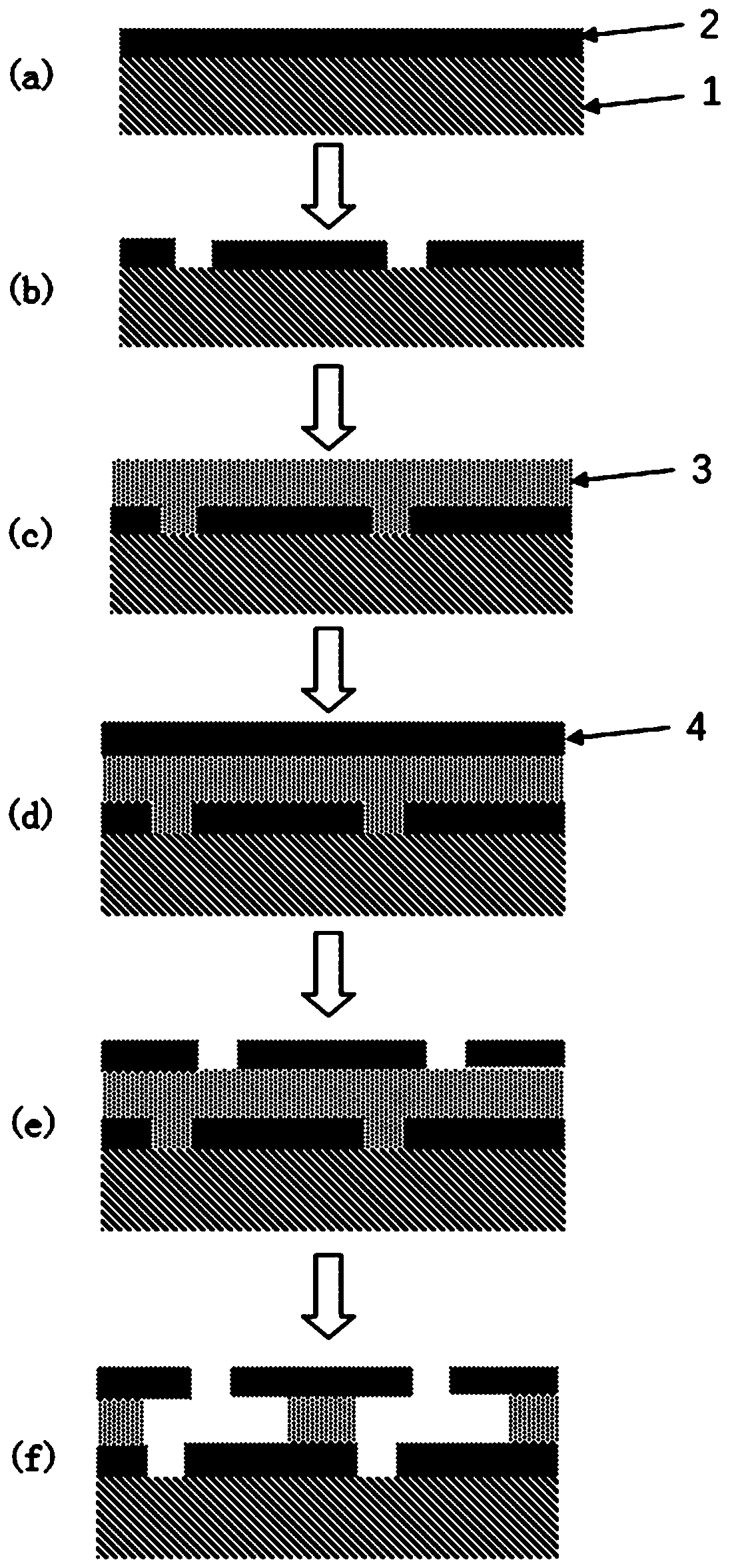

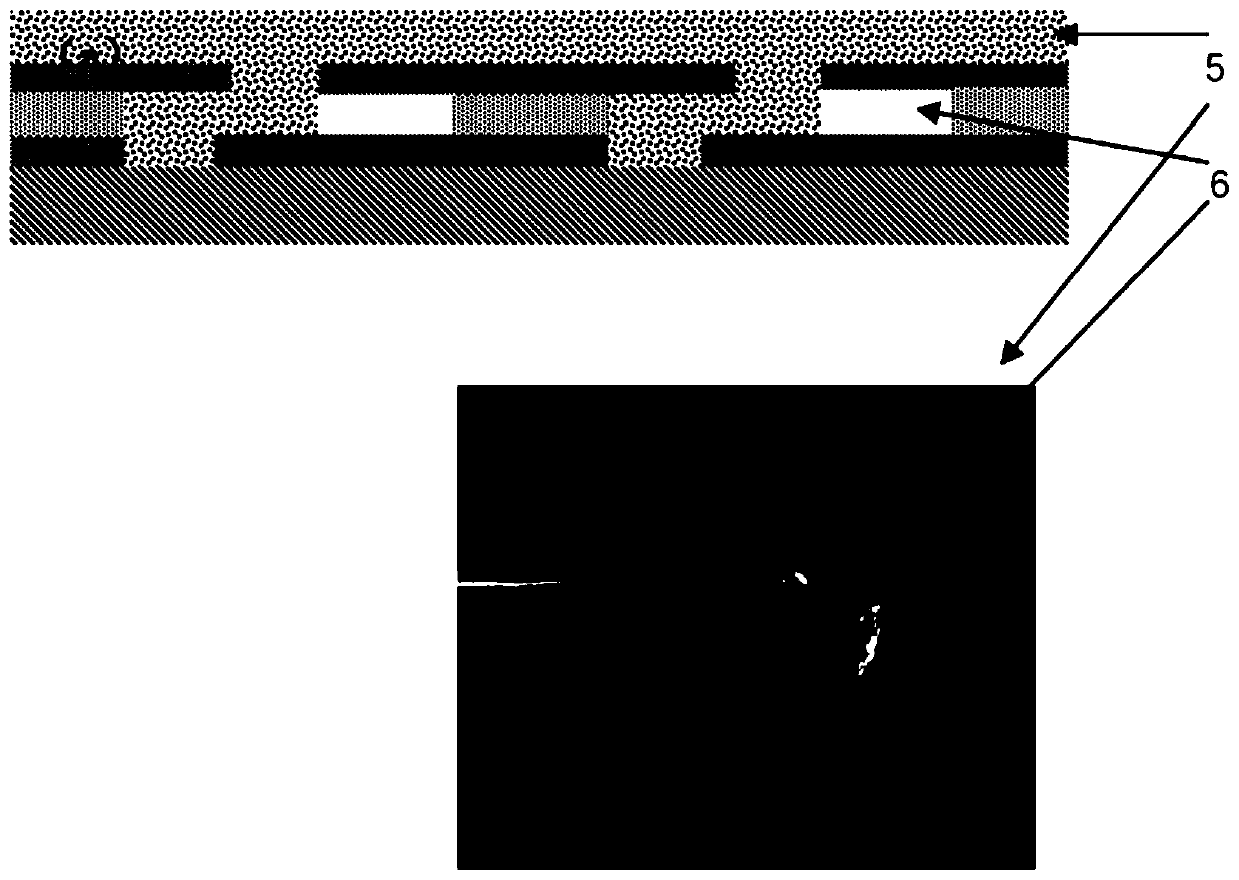

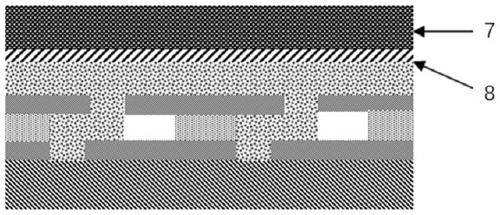

[0053] The core of the technical solution of the present invention lies in the combination of graphic substrate structure design and wet etching process. In terms of substrate structure design, the new 3D laminated substrate technology is mainly adopted. In this technology, the graphic positions of the upper and lower masks are offset from each other. After the etching process, the connection between the upper and lower mask windows is opened, so that GaN can be grown meandering from the bottom window and eventually drilled out of the top window. Such as figure 1 As shown, it specifically includes the following steps:

[0054] 1) Deposit the underlying mask layer 2 (first layer mask) on the substrate 1, such as figure 1 As shown in (a) figure....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com