Mine underground filling mortar

A technology of mortar and mine, which is applied in the field of filling mortar in mines, can solve the problems of high cost, raw material mining environment and natural resource impact, and achieve the effects of low cost, protection of natural resources and ecological environment, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

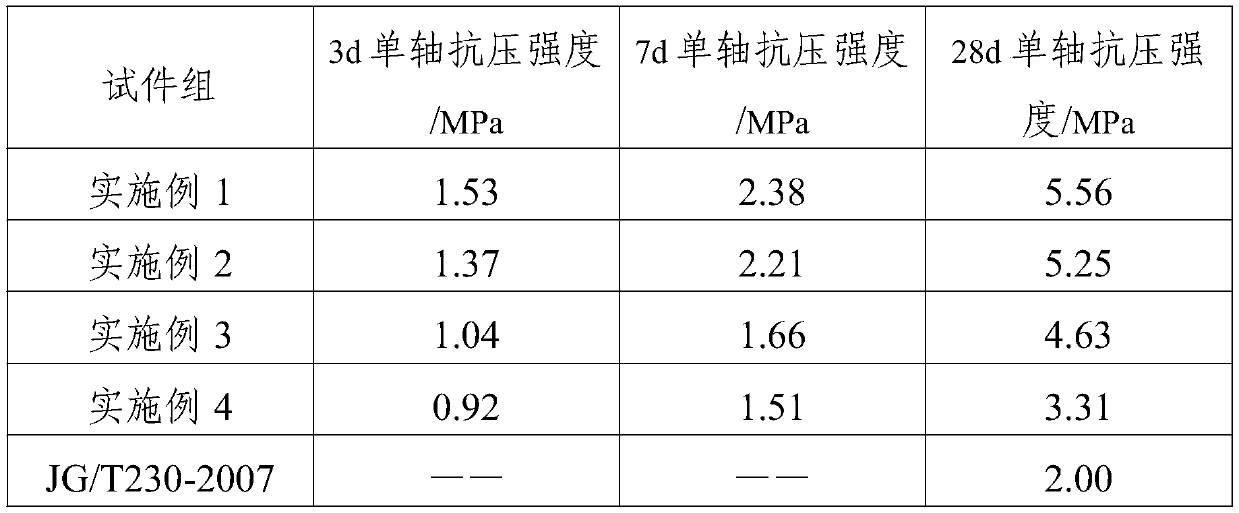

Examples

Embodiment 1

[0029] Weigh 15 parts of iron tailings powder, 60 parts of fine slag powder, 15 parts of quicklime and 10 parts of desulfurized ash and mix them uniformly to obtain the cementitious material for filling mortar in the mine. Mix the cementitious material filled underground in the above-mentioned mine with water and iron tailings in a ratio of 1:2:4 to make filling mortar.

[0030] Put the prepared filling mortar into a mold of 40mm×40mm×160mm for molding, put the formed test piece in an environment with a temperature of about 20°C and a relative humidity of not less than 50% for curing, remove the mold after 24 hours, and remove the The molded specimens were placed in warm water at about 20°C for hydroculture.

Embodiment 2

[0032] Weigh 25 parts of iron tailings powder, 45 parts of fine slag powder, 20 parts of quicklime and 10 parts of desulfurized ash and mix evenly to obtain the cementitious material for filling mortar in the mine. Mix the cementitious material filled underground in the above-mentioned mine with water and iron tailing sand in a ratio of 1:2:6 to make filling mortar.

[0033] Put the prepared filling mortar into a mold of 40mm×40mm×160mm for molding, put the formed test piece in an environment with a temperature of about 20°C and a relative humidity of not less than 50% for curing, remove the mold after 24 hours, and remove the The molded specimens were placed in warm water at about 20°C for hydroculture.

Embodiment 3

[0035] Weigh 15 parts of iron tailings powder, 60 parts of fine slag powder, 15 parts of quicklime and 10 parts of desulfurized ash and mix them uniformly to obtain the cementitious material for filling mortar in the mine. Mix the cementitious material filled in the underground of the above mine with water and iron tailing sand in a ratio of 1:2.5:8 to make filling mortar.

[0036] Put the prepared filling mortar into a mold of 40mm×40mm×160mm for molding, put the formed test piece in an environment with a temperature of about 20°C and a relative humidity of not less than 50% for curing, remove the mold after 24 hours, and remove the The molded specimens were placed in warm water at about 20°C for hydroculture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com