Additive manufacturing method of imdp pellets and imdp pellets

An additive manufacturing and pellet technology, applied in the IMDP pellet additive manufacturing method and the IMDP pellet field, can solve the problems of irregular distribution, inability to thin, inability to process chamfers and dish shapes, etc., to improve thermal expansion and The effect of irradiation swelling, relieving thermal stress deformation and eliminating safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

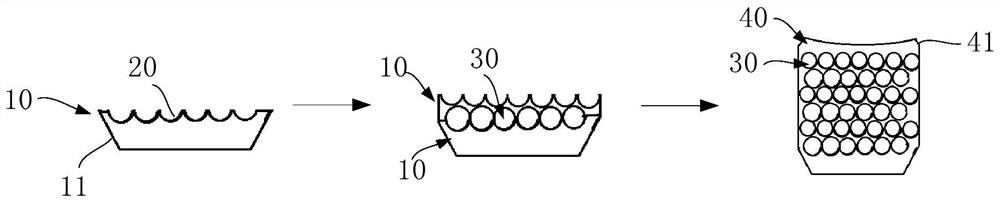

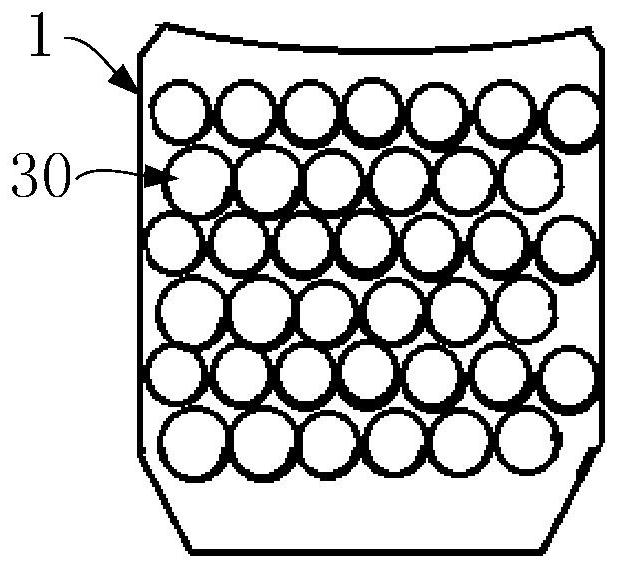

[0035] The IMDP pellet additive manufacturing method of the present invention may comprise the following steps:

[0036] S1. Put the base material into the three-dimensional printer.

[0037] The raw material of the matrix can be realized by using the raw material of the IMDP pellet matrix in the prior art, such as SiC, ZrC and so on. The matrix material can be loaded into the 3D printer in powder or fluidized state.

[0038] S2. The printer head of the three-dimensional printer outputs the molten substrate material, and prints a substrate unit with one or more grooves arranged at a set distance on the printing platform.

[0039] S3. The robotic arm cooperating with the 3D printer puts the TRISO particles into the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com