Door and window intelligent automatic production line and door and window intelligent automatic production method

An automatic production method and automatic production line technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of large labor intensity of workers, large production line area, cumbersome manual handling, etc., to reduce the risk of damage, not easy Pull out, avoid the effect of difficult installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. The following experimental examples and examples are used to further illustrate but not limit the present invention.

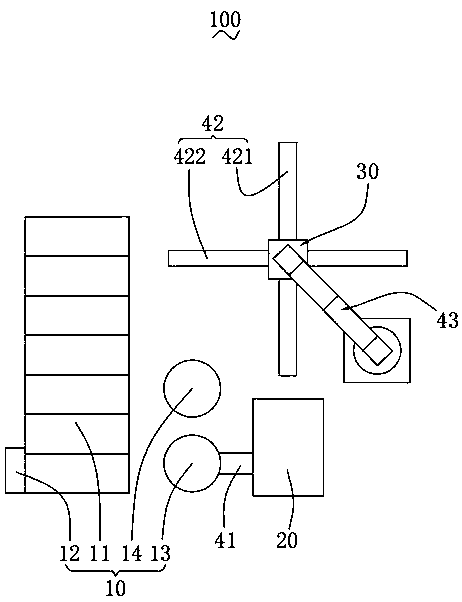

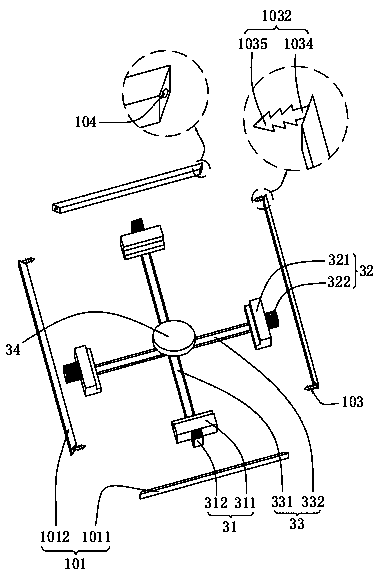

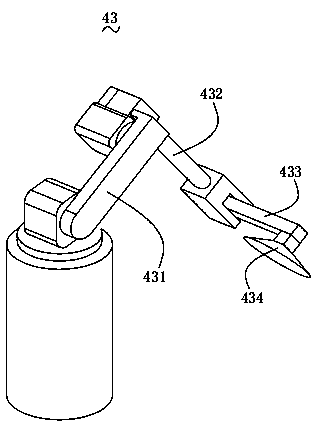

[0037] Please refer to Figure 1 to Figure 4 , the present invention provides a door and window intelligent automatic production line 100, which is used for the automatic production and installation of door and window outer frames and inner leaves. 30. Transportation mechanism and numerical control mechanism (not shown in the figure). Wherein, the unloading mechanism 10, the inner fan assembly mechanism 20 and the outer frame assembly mechanism 30 are sequentially connected.

[0038] The blanking mechanism 10 shapes the raw material into an outer frame profile 101 and an inner fan profile 102 that can be directly assembled through cutting, drilling and milling processes.

[0039] Specifically, the blanking mechanism 10 includes a ful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com