A kind of atmospheric pressure low temperature vulcanized self-absorbing water vapor rubber compound and its preparation process and application

A low-temperature vulcanization and rubber compound technology, which is applied in the field of atmospheric pressure and low-temperature vulcanization self-absorption air rubber compound, can solve the problems affecting the density and overall physical and mechanical properties of the vulcanized compound, and cannot meet the construction requirements, and achieves good applicability. , to avoid scorch, to ensure the effect of use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

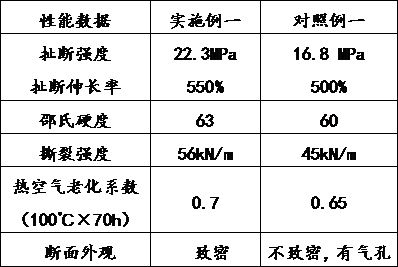

Embodiment 1

[0023] An application method of a self-absorbing water-air rubber compound vulcanized under normal pressure and low temperature in the preparation of rubber lining products:

[0024] S1. Weighing and compounding: Weigh each component according to the formula; then mix calcium oxide, aluminum oxide, and charcoal powder evenly to prepare a water-absorbing compounding agent; mix basic raw rubber, plasticizer, microcrystalline paraffin , The reinforcing filler is mixed evenly to obtain a premix; the vulcanizing agent and vulcanization accelerator are weighed and placed in isolation;

[0025] S2. Mastication: Evenly mix the premix and two-thirds of the water-absorbing compounding agent into the rubber mixing equipment for plastication to obtain plasticized rubber;

[0026] S3. One-stage mixing: mix the masticated rubber, vulcanization accelerator, zinc oxide, stearic acid, anti-aging agent and the remaining water-absorbing compounding agent evenly and put them into the internal mix...

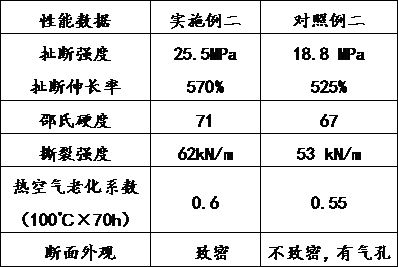

Embodiment 2

[0039] An application method of a self-absorbing water-air rubber compound vulcanized under normal pressure and low temperature in the preparation of rubber lining products:

[0040] S1. Weighing and compounding: Weigh each component according to the formula; then mix calcium oxide, aluminum oxide, and charcoal powder evenly to prepare a water-absorbing compounding agent; mix basic raw rubber, plasticizer, microcrystalline paraffin , The reinforcing filler is mixed evenly to obtain a premix; the vulcanizing agent and vulcanization accelerator are weighed and placed in isolation;

[0041] S2. Mastication: Evenly mix the premix and 4 / 5 of the water-absorbing compounding agent into the rubber mixing equipment for plastication to obtain plasticized rubber;

[0042] S3. One-stage mixing: mix the masticated rubber, vulcanization accelerator, zinc oxide, stearic acid, anti-aging agent and the remaining water-absorbing compounding agent evenly and put them into the internal mixer for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com