Super-hydrophobic coating for corrosion resistance and freeze thawing resistance of concrete and preparation method thereof

A super-hydrophobic coating, anti-freeze-thaw technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of complex coating construction, loss of protective effect, high cost, and achieve the benefits of rapid construction, improved ventilation and waterproofing effect, drying time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

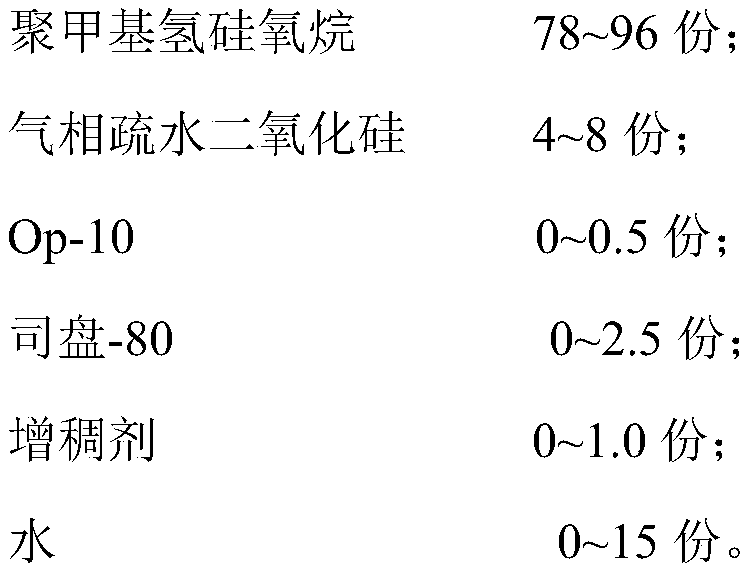

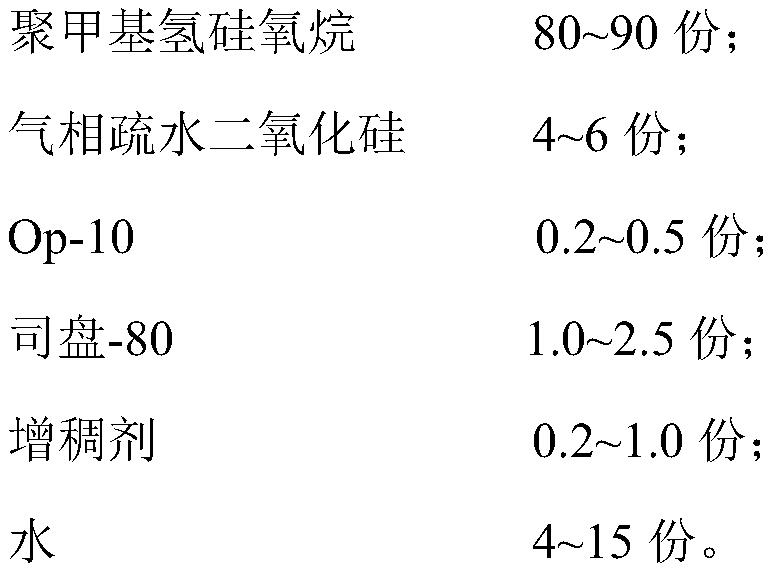

[0029] A kind of superhydrophobic coating that is used for concrete anticorrosion, freeze-thaw resistance, its composition is calculated as follows by mass parts:

[0030] 90 parts of polymethyl hydrogen siloxane;

[0031] 4 parts of fumed hydrophobic silica;

[0032] Op-10 0.2 parts;

[0033] Span-80 1.0 parts;

[0034] 0.5 parts of TT-60;

[0035] 4.3 parts of water.

[0036] Wherein, the gas-phase hydrophobic silica is Evonik Degussa gas-phase hydrophobic silica R972, with a particle size of 7-16nm and a specific surface area of 80-280m 2 / g.

[0037] The preparation process of the superhydrophobic coating for concrete anticorrosion and freeze-thaw resistance described in this embodiment is as follows:

[0038] S1: Add 43g of water, 2g of op-10 and 10g of Span-80 into a 2L reactor, stir, disperse and shear at 1000rpm for 10min at room temperature;

[0039] S2: Add 5g of TT-60 to the system in step S1, increase the rotation speed to 2000rpm, then add 900g of polymet...

Embodiment 2

[0042] A kind of superhydrophobic coating that is used for concrete anticorrosion, freeze-thaw resistance, its composition is calculated as follows by mass parts:

[0043] 94 parts of polymethyl hydrogen siloxane;

[0044] 6.0 parts of fumed hydrophobic silica;

[0045] Wherein, the gas-phase hydrophobic silica is Evonik Degussa gas-phase hydrophobic silica R104, with a particle size of 7-16nm and a specific surface area of 80-280m 2 / g.

[0046] The preparation process of the superhydrophobic coating used for concrete anticorrosion and freeze-thaw resistance described in this example is as follows: add 940g polymethylhydrogensiloxane to a 2L reactor and increase the rotating speed to 2000rpm, then drop and shear for 30min The rotation speed was reduced to 1000rpm, and then 60g of hydrophobic silica was added, dispersed and sheared for 30min, and a stable transparent paste was obtained.

Embodiment 3

[0048] A kind of superhydrophobic coating that is used for concrete anticorrosion, freeze-thaw resistance, its composition is calculated as follows by mass parts:

[0049] 84 parts of polymethyl hydrogen siloxane;

[0050] 6 parts of fumed hydrophobic silica;

[0051] Op-10 0.5 parts;

[0052] Span-80 2.5 parts;

[0053] 0.2 parts of TT-60;

[0054] 6.8 parts of water;

[0055] The gas-phase hydrophobic silica is Evonik Degussa gas-phase hydrophobic silica R816, with a particle size of 7-16nm and a specific surface area of 80-280m 2 / g.

[0056] The preparation process of the superhydrophobic coating used for concrete anticorrosion and freeze-thaw resistance according to the present invention is basically the same as that of Example 1 except for the amount of components, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com