Anti-oxidation method for light rare earth metal

A light rare earth, anti-oxidation technology, applied in the field of materials, can solve the problems of prone to automatic combustion, high cost of storage devices, unsafe use, etc., and achieve the effects of wide range of use, convenient storage and pure products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

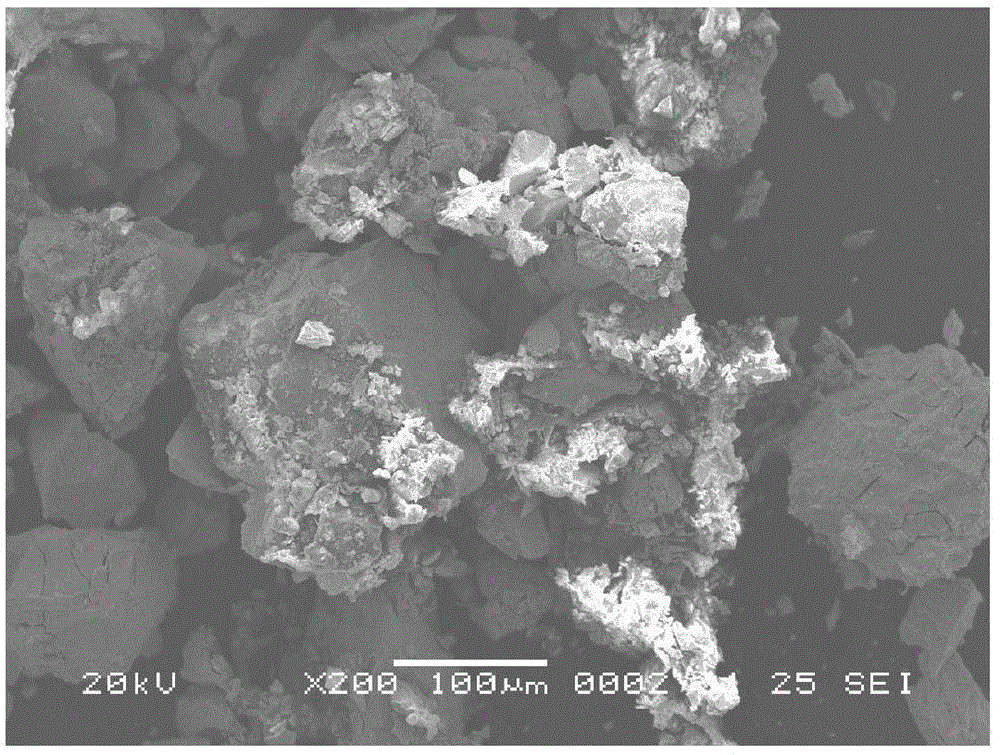

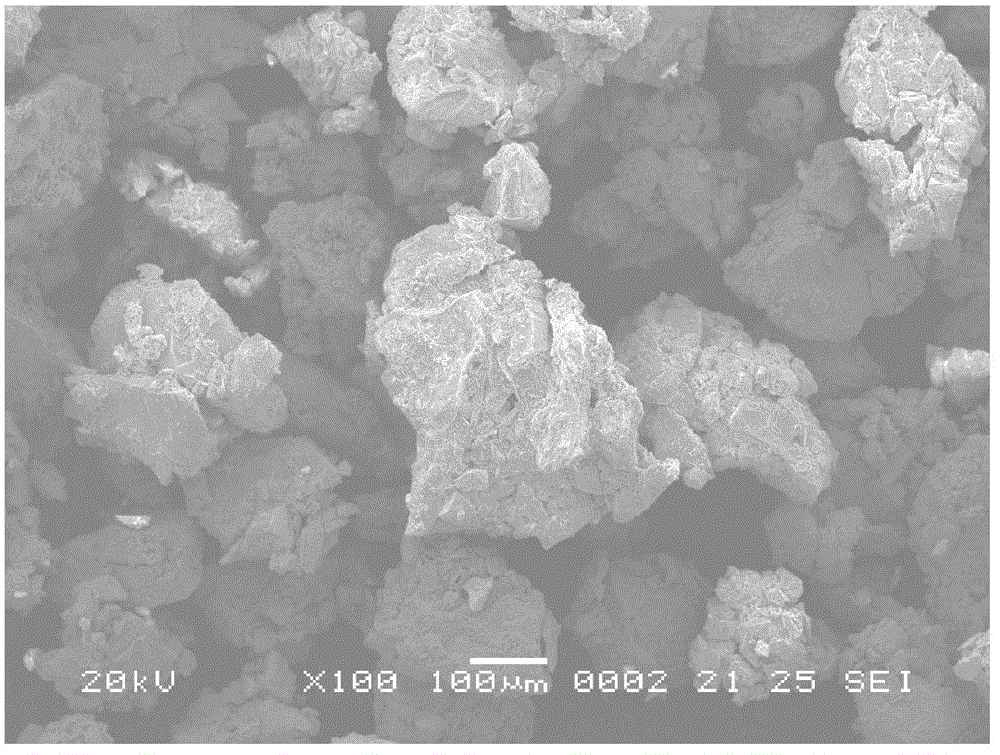

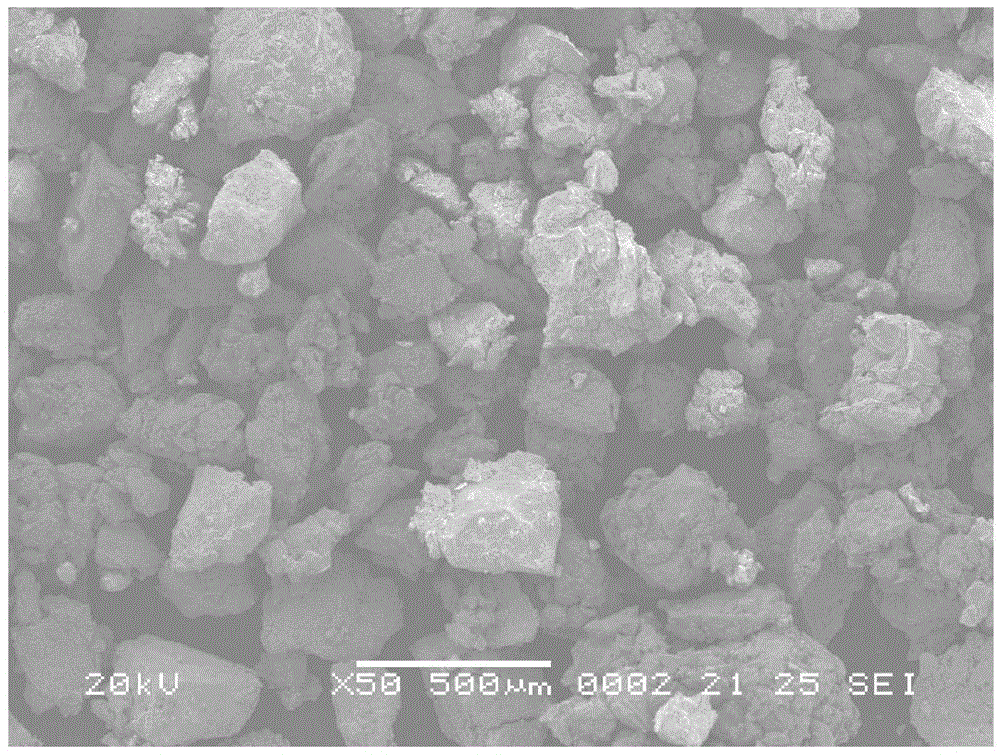

Image

Examples

Embodiment 1

[0031] (1) Add 800ml of butyl acetate to a dry 1000mL three-neck flask, install a condensing reflux tube and a thermometer, and let in nitrogen gas; take metal sodium, scrape off the surface oxide with a knife, and cut into small slices about 0.5mm thick , add 8g flake metallic sodium to butyl acetate, heat to 128°C; after refluxing for 8 hours, add benzophenone reagent, the solution turns blue, and the blue color becomes deeper and deeper with time, indicating that the water is clean; Finally, distill and collect the butyl acetate distillate at 126°C for subsequent use; the method of removing water from carbon tetrachloride, ethyl acetate, acetone, and acetonitrile is the same as above, but the distillation temperature is different;

[0032] (2) Take 3g of granular polyhydroxypropylmethyl acrylate, add it to a three-necked flask filled with 97mL of anhydrous butyl acetate, and heat it to 60°C in a water bath until the polyhydroxypropylmethylacrylate is completely dissolved to ...

Embodiment 2

[0037] (1) Add 20g of polybis-azidomethoxetane (PBAMO) into 380mL of anhydrous ethyl acetate, stir, and heat to 50°C until NC is completely dissolved to form a glue, which is ready for use;

[0038](2) In the glove box, weigh 20g La and put it into a watch glass, add 8g of 5% polybisazidemethoxetane (PBAMO) solution, mix well, and knead it by hand after the solvent evaporates for 20min. Synthesize a flexible mass, press down and move on a 20-mesh copper sieve to make the falling matter form granular matter, and dry the granular solid material in an oven at a temperature of 47°C and a vacuum degree of 0.03 for 5 hours to obtain Antioxidant treated La. After anti-oxidation treatment, La can be stored for a long time at a relative humidity of 80% and a temperature of 20°C, which effectively improves the anti-oxidation ability of La, and can be safely used in explosives and propellants.

Embodiment 3

[0040] (1) Add 10g of beeswax into 190mL of anhydrous acetone, stir, and heat to 50°C until the beeswax is completely dissolved to form a glue, and set aside;

[0041] (2) Add 25gLa into a 300mL three-neck flask and add 200mL of anhydrous acetonitrile, install a stirrer and a thermometer, and when the temperature is raised to 58°C with stirring, add 20mL of the glue solution prepared in step (1) dropwise into the reaction flask; 42 drops per minute, the stirring speed is 300r / min, continue to stir for 15min after the dropwise addition, and cool to normal temperature;

[0042] (3) Pour the coated La into a funnel for filtration; put the filtered solid material in an oven at a temperature of 42° C. and a vacuum of 0.029 for 12 hours to obtain the antioxidation-treated La. The initial decomposition temperature of this antioxidant-treated La was 390°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com