Novel environmentally-friendly cutting liquid and preparation method thereof

A cutting fluid, environmental protection technology, applied in the field of new environmental protection cutting fluid and its preparation, can solve the problems of environmental pollution, non-ferrous metal corrosion, etc., and achieve the effect of superior performance, easy handling, and excellent anti-corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

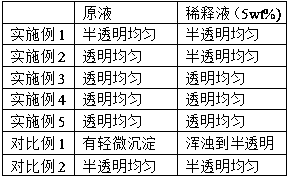

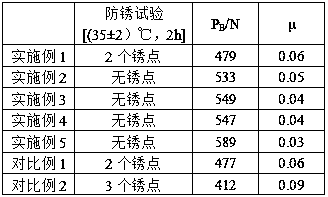

Examples

Embodiment 1

[0034] (1) Add 27 parts of water into the reactor, raise the temperature to 60°C, turn on the stirring device, then add 8 parts of coconut oil fatty acid diethanolamide, 14 parts of polyethylene glycol eicosenoic acid triethanolamide borate Stir each portion for 15 minutes;

[0035] (2) Then add 18 parts of N5 white oil, 9 parts of dialkyl dithiocarbamate, 2 parts of corrosion inhibitor, 2 parts of ethanol, 2 parts of emulsifier, 7 parts of polyether L61, and stir for 30 minutes;

[0036] (3) Lower the temperature to 40°C, add 0.5 parts of sodium pentachlorophenolate, and continue stirring for 20 minutes.

[0037] The emulsifier is a mixture of sodium oleate and oleic acid in a weight ratio of 5:1.

[0038] The anticorrosion agent is made by mixing sodium carbonate, sodium gluconate and borax according to the mass ratio of 1:2:2.

Embodiment 2

[0040] (1) Add 20 parts of water into the reactor, raise the temperature to 60°C, turn on the stirring device, then add 15 parts of coconut oil fatty acid diethanolamide, polyethylene glycol type eicosenoic acid triethanolamide borate 7 Stir each portion for 15 minutes;

[0041] (2) Then add 26 parts of N5 white oil, 3 parts of dialkyl dithiocarbamate, 4 parts of corrosion inhibitor, 1.2 parts of ethanol, 5 parts of emulsifier, 3 parts of polyether L61, and stir for 30 minutes;

[0042] (3) Lower the temperature to 40°C, add 1.6 parts of sodium pentachlorophenolate, and continue stirring for 20 minutes.

[0043] The emulsifier is a mixture of sodium oleate and oleic acid in a weight ratio of 5:1.

[0044] The anticorrosion agent is made by mixing sodium carbonate, sodium gluconate and borax according to the mass ratio of 1:2:2.

Embodiment 3

[0046] (1) Add 25 parts of water into the reactor, raise the temperature to 60°C, turn on the stirring device, then add 10 parts of coconut oil fatty acid diethanolamide, 12 parts of polyethylene glycol eicosenoic acid triethanolamide borate Stir each portion for 15 minutes;

[0047] (2) Then add 20 parts of N5 white oil, 8 parts of dialkyl dithiocarbamate, 2.8 parts of corrosion inhibitor, 1.9 parts of ethanol, 2.9 parts of emulsifier, 6 parts of polyether L61, and stir for 30 minutes;

[0048] (3) Lower the temperature to 40°C, add 0.8 parts of sodium pentachlorophenate, and continue stirring for 20 minutes.

[0049] The emulsifier is a mixture of sodium oleate and oleic acid in a weight ratio of 5:1.

[0050] The anti-corrosion agent is made by mixing sodium carbonate, sodium gluconate and borax according to the mass ratio of 1:2:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com