Apparatus and method for automobile disassembly waste pyrolysis gasification based on vertical fixed bed

A technology of pyrolysis gasification and automobile dismantling, which is applied in the fields of solid waste removal, scrapped vehicle recycling, motor vehicles, etc. It can solve problems affecting equipment operation, low calorific value of syngas, and excessive tar, so as to achieve easy control, The effect of low investment cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

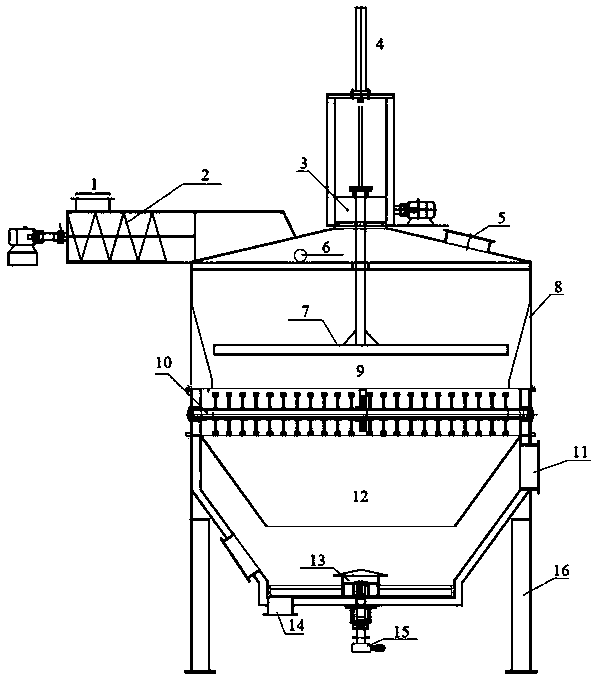

[0023] Such as figure 1 Shown, a kind of automobile dismantling waste pyrolysis gasification device based on vertical fixed bed, comprises pyrolysis gasification furnace body 8, pyrolysis gasification furnace body 8 is supported by pyrolysis gasification furnace bracket 16, bottom Set the ash discharge mixer 13 and the ash discharge outlet 14, the ash discharge mixer 13 is connected to the ash discharge stirring motor through the ash discharge reducer 15, the top center is provided with a suction port 4, and the left and right sides of the top are respectively equipped with a sight glass observation port 6 and maintenance Mouth 5.

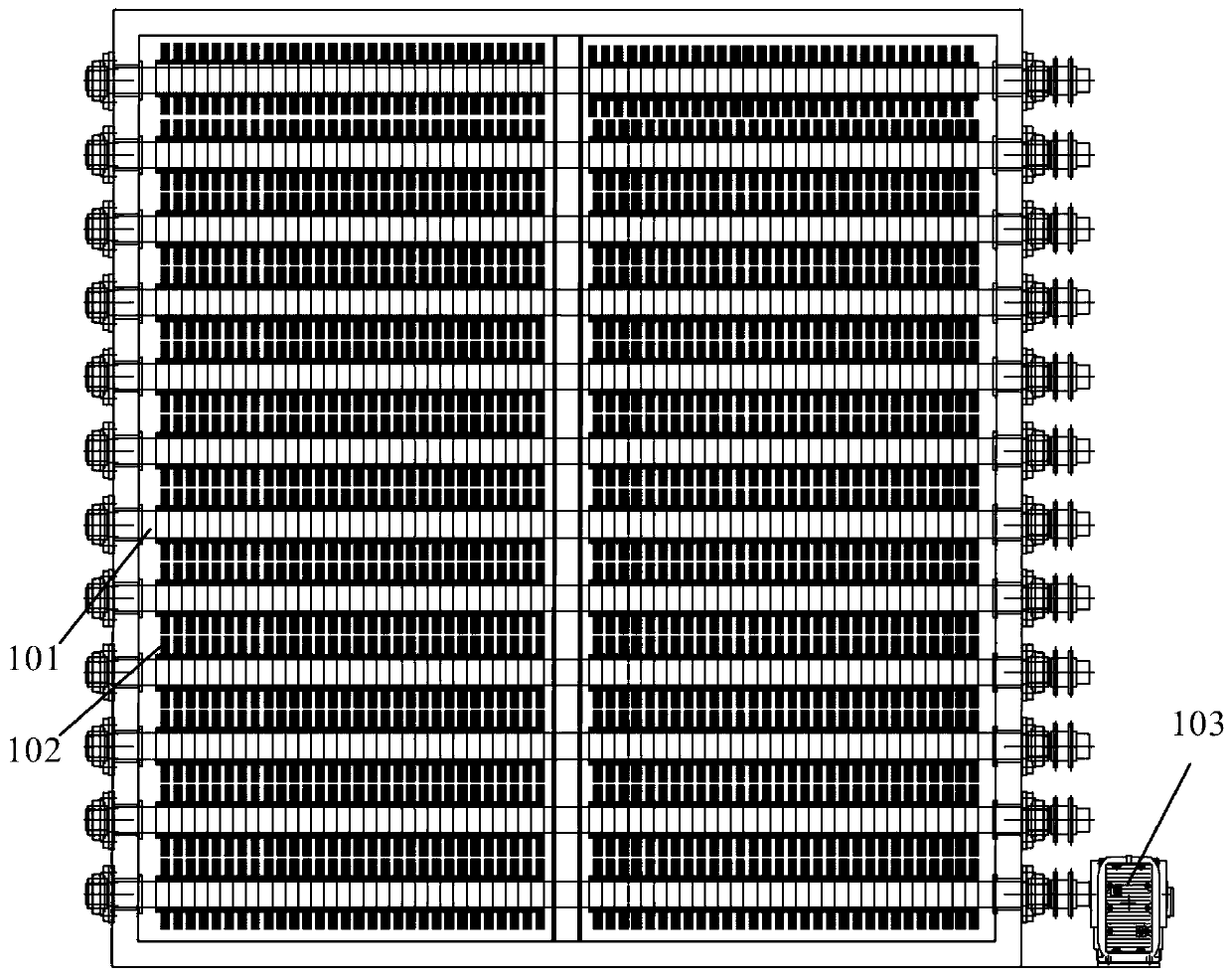

[0024] The pyrolysis gasification furnace body 8 is provided with a pyrolysis gasification chamber 9 and a bottomless ash collection chamber 12, and a gas outlet 11 connected to an exhaust fan is provided on the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com