Freeze dryer and supporting plate feeding and discharging system thereof

A technology of feeding and discharging materials, freeze-drying machine, applied in the field of freeze-drying, can solve the problems of spilled liquid medicine, ignoring friction, generating friction debris, etc., so as to avoid incomplete cleaning and sterilization, avoid loss and scratches, and solve friction effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

[0059] The first specific embodiment of the present invention provides a tray loading and unloading system for a freeze dryer.

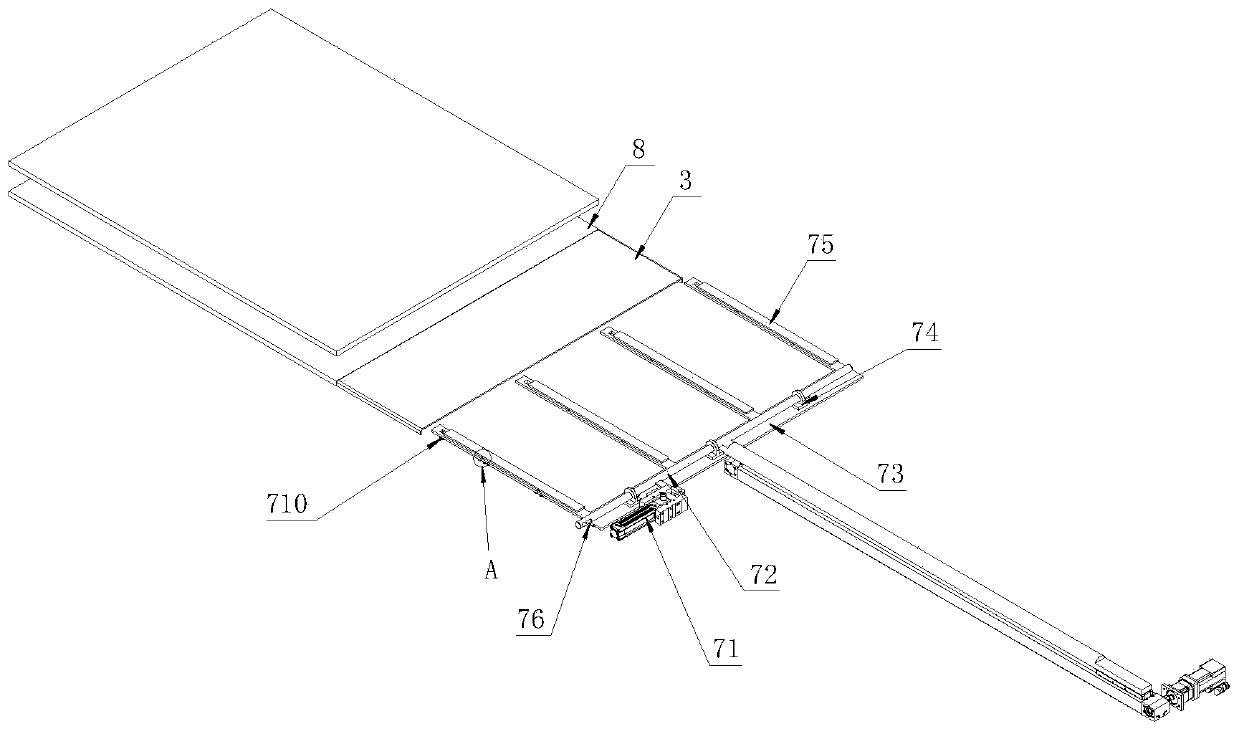

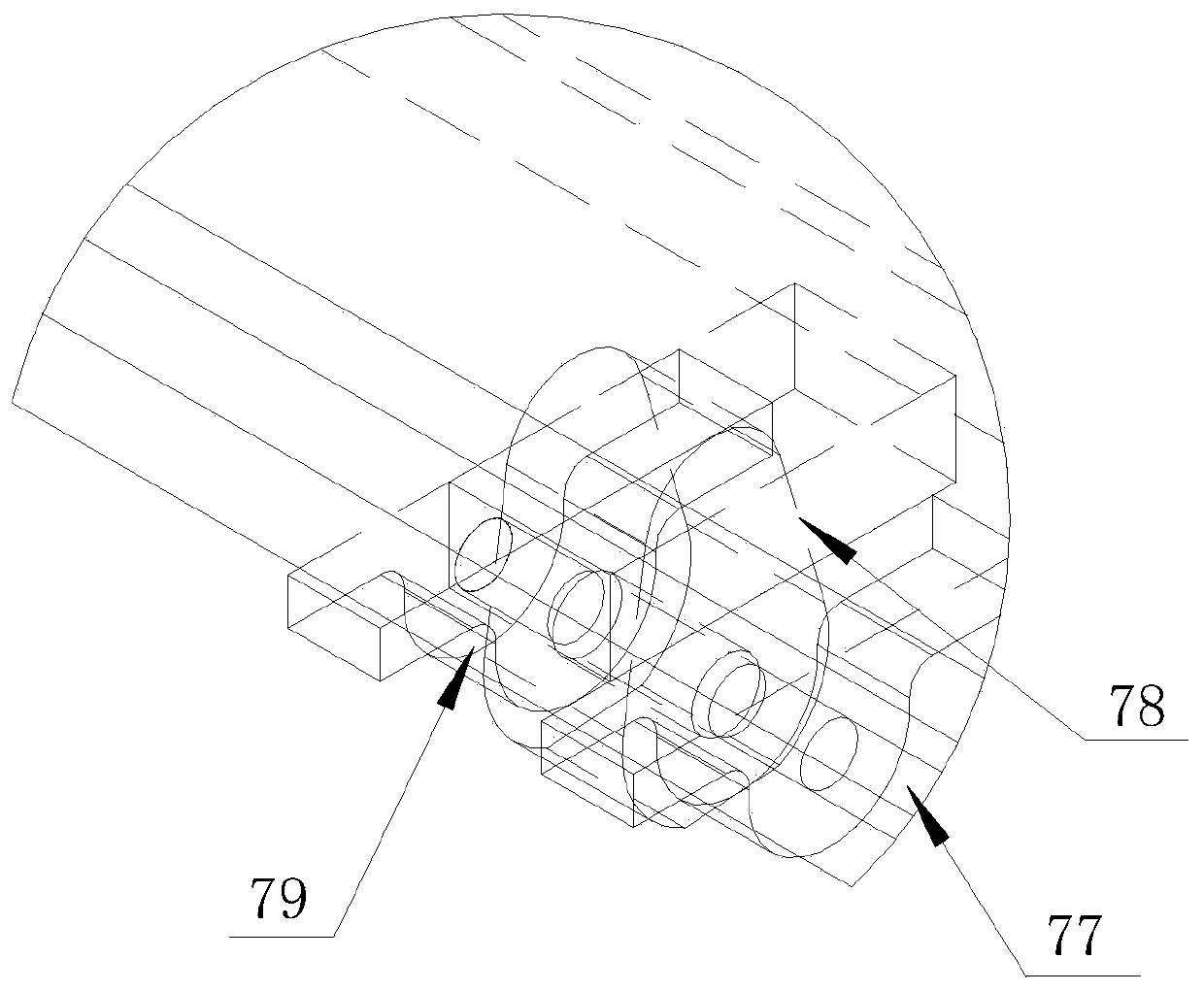

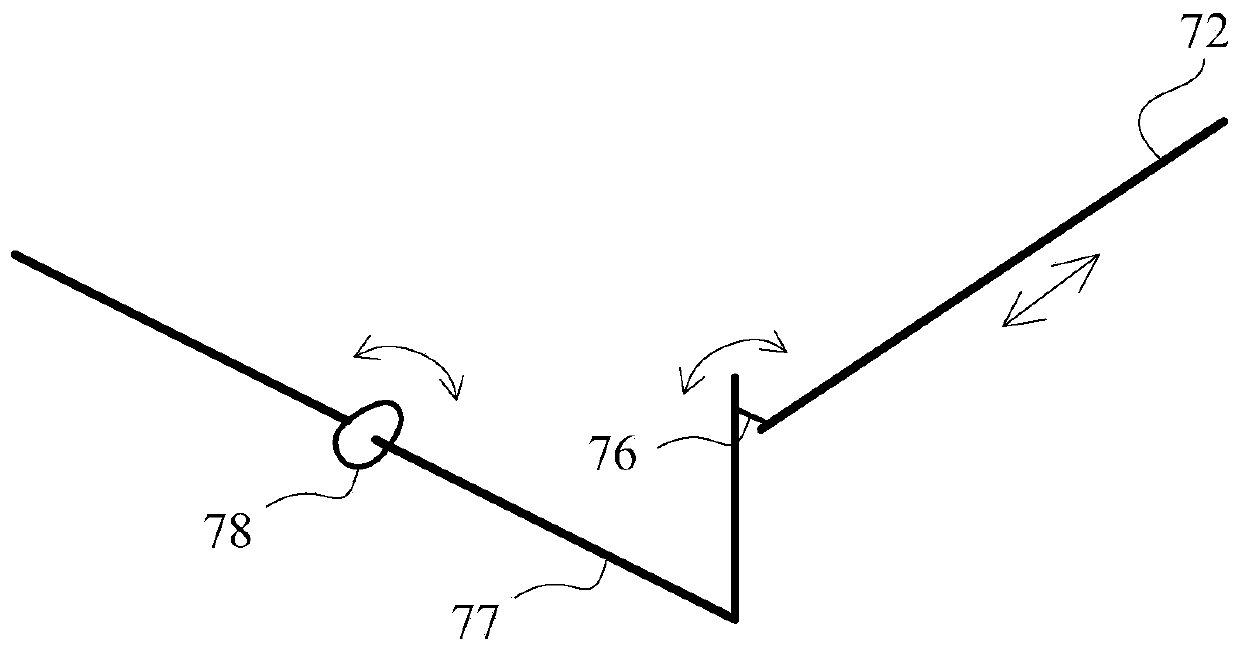

[0060] see Figure 1 to Figure 5 , figure 1 An axonometric view of the freeze dryer tray feeding and discharging system provided for the first specific embodiment of the present invention; figure 2 for figure 1 Partial enlarged perspective view of area A in middle; image 3 The principle diagram of the lifting mechanism in the tray feeding and discharging system of the freeze dryer provided by the first specific embodiment of the present invention; Figure 4 The front view of the freeze dryer tray feeding and discharging system provided for the first specific embodiment of the present invention; Figure 5 A side view of the tray feeding and discharging system of the freeze dryer provided in the first specific embodiment of the present invention.

[0061] The freeze dryer tray feeding and discharging system provided by the first specific embodim...

no. 2 Embodiment

[0096] The second specific embodiment of the present invention provides a freeze dryer.

[0097] see Figure 6 to Figure 9 , Figure 6 An axonometric view of the freeze dryer provided for the second specific embodiment of the present invention; Figure 7 The front view of the freeze dryer provided for the second specific embodiment of the present invention; Figure 8 A side view of the freeze dryer provided for the second specific embodiment of the present invention; Figure 9 A top view of the freeze dryer provided for the second specific embodiment of the present invention.

[0098] The freeze dryer provided by the second specific embodiment of the present invention includes a box body 1, a feed-in and discharge base 5 and a tray feed-in and discharge system. The material system is the freeze dryer tray feeding and discharging system provided in the first specific embodiment of the present invention.

[0099] During the feeding and discharging process, the tray feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com