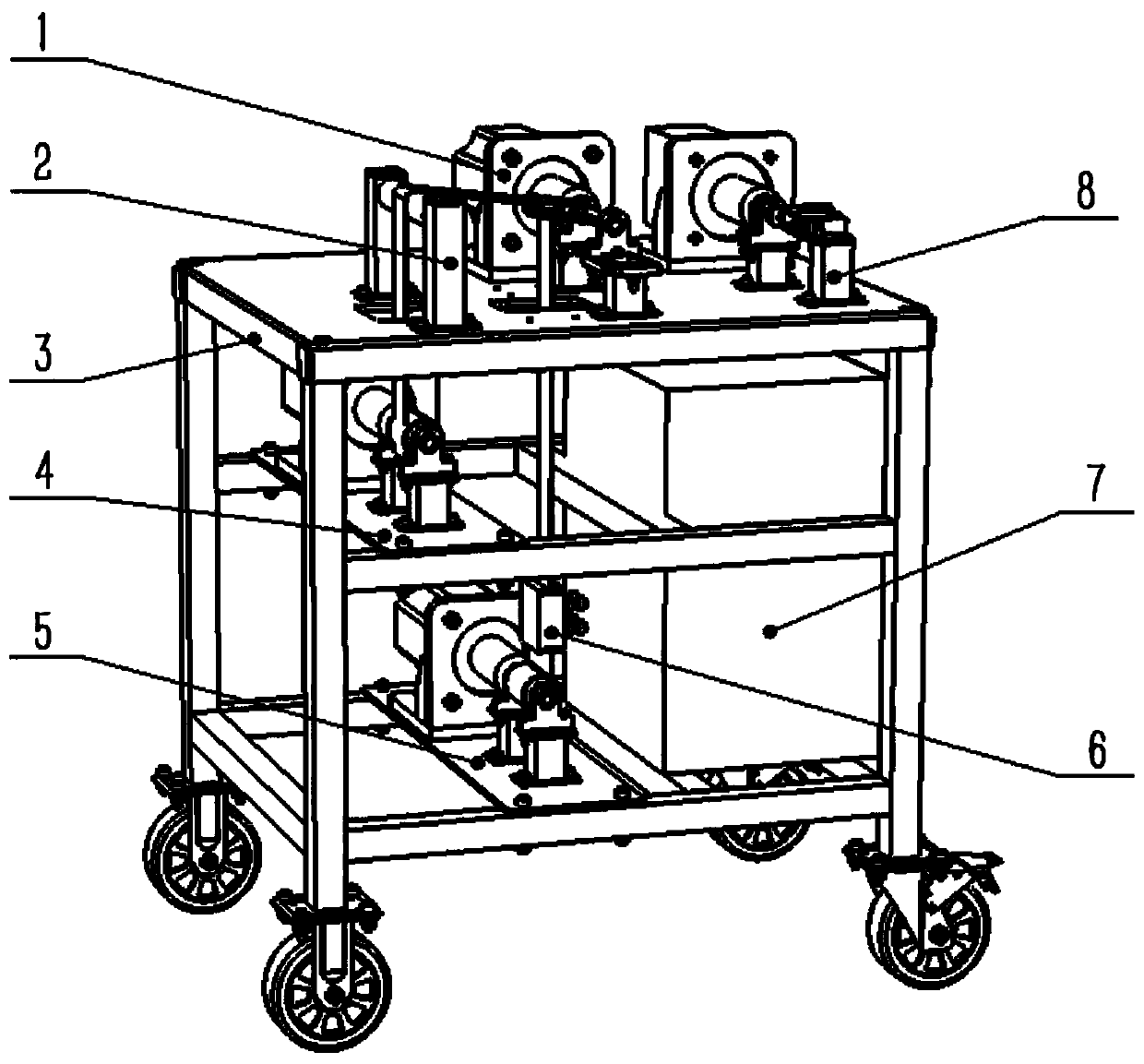

Passenger safety belt comprehensive performance test board

A technology for comprehensive performance testing and seat belts, which can be used in testing wear resistance, testing of mechanical components, testing of machine/structural components, etc. Effects of accuracy and waste, ensuring traceability, ensuring controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

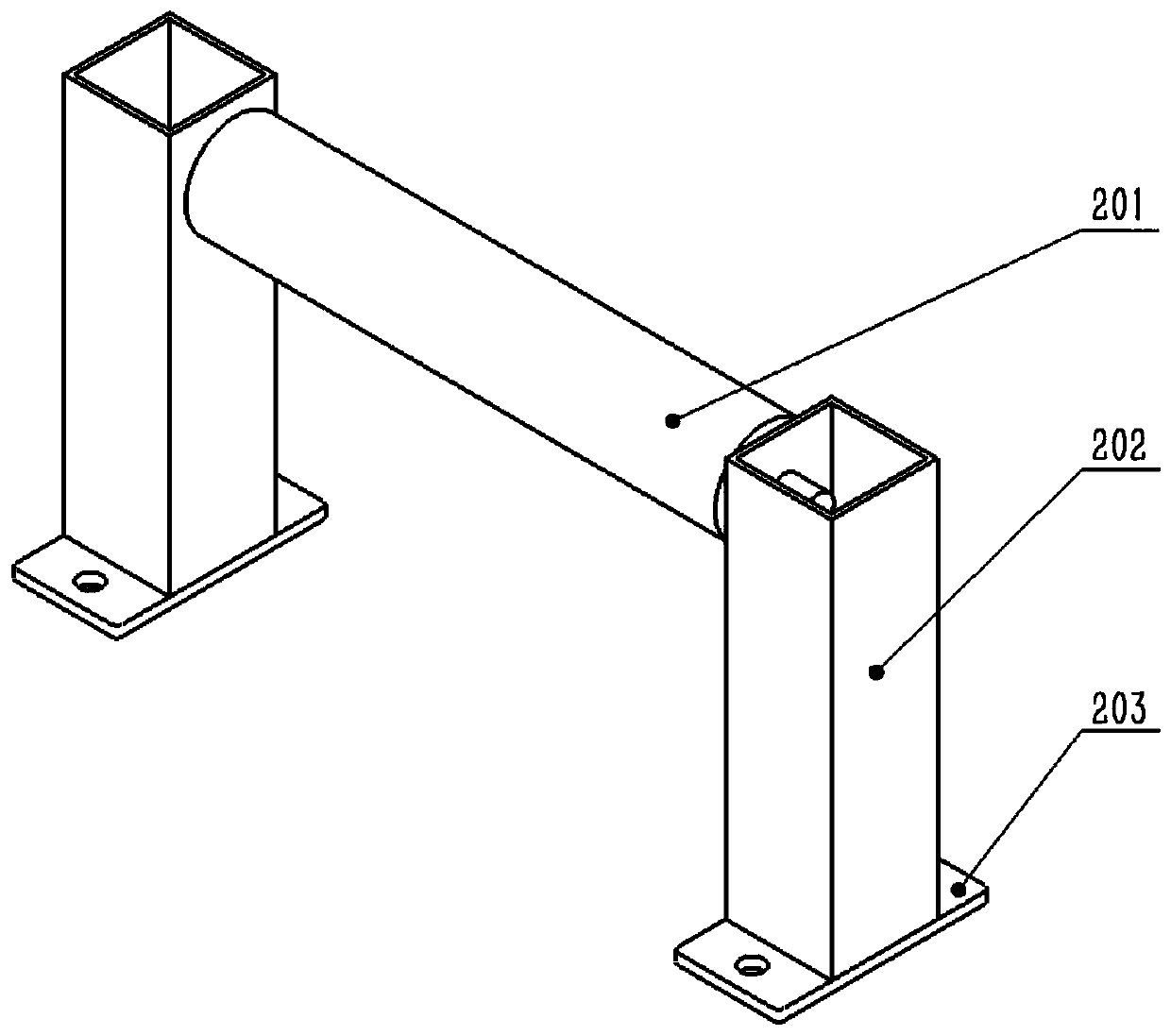

[0058] The present invention can carry out 2500 wear-resisting tests of the safety belt, and the purpose of the test is to simulate the passenger safety belt of a civil aircraft in the service life, and to verify the influence of the passenger pulling the passenger safety belt on the service life under extreme force conditions, and the basic principle of the test is : According to the schematic diagram of the CTSOA manual (see attached Figure 36 ), the passenger seat belt strap passes through the buckle (see attached Figure 37 ), one end of the passenger safety belt strap is bound with a counterweight (6) with a weight of 1.361kg, and the other end pulls the passenger safety belt strap. When the counterweight (6) rises, the angle between the passenger safety belt strap and the horizontal plane is 8 ±2°, when the weight falls, the angle between the passenger seat belt belt and the horizontal plane is 0°, the manual requires that the number of cycles per minute is between 16-1...

Embodiment 2

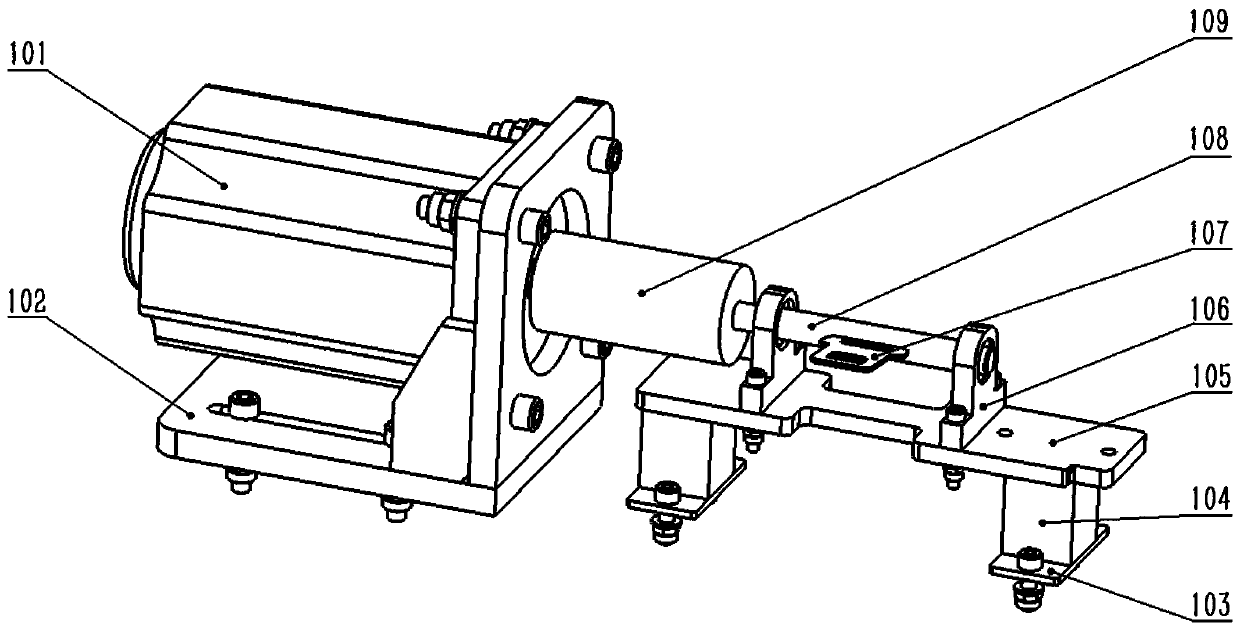

[0060] The present invention can carry out described safety belt included angle reliability test, and test purpose is to simulate civil aircraft in flight process, and passenger safety belt can play safe, effective binding force to passenger, and the basic principle of test is: CTSOA manual requirement Fix the passenger seat belt to the test equipment to ensure that the passenger seat belt is vertical; when starting the test, pull one end of the passenger seat belt at a speed of 500±50mm / min, and slowly change (1r / min±0.2r / min) the buckle Angle with the horizontal, when the tension reaches 89N, stop rotating; as attached Figure 40 As shown, use the bolts and nuts to fasten the seat belt buckle ( Figure 37 ) is installed on the seat belt buckle plate (107) of the buckle angle rotation device (1), to ensure that the initial position of the seat belt buckle plate (107) is horizontal, and the passenger seat belt belt passes through the seat belt buckle ( Figure 37), one end of...

Embodiment 3

[0062] The present invention can carry out described lock buckle constant force 130N to rotate 200 times test, and test purpose is to simulate civil aircraft passenger safety belt in service life, verify the life span of lock buckle under extreme force opening and closing state, the basic principle of this experiment is : The CTSOA manual requires the use of a force of 130±13N to open and close the lock, the frequency shall not exceed 30 times / min, and the cycle shall be 200 times; as attached Figure 42 As shown, the distance between the reliability test rotating shaft (807) and the locking toggle shaft (809) is 58mm, the output constant force is required to be 130N, and the output torque of the servo motor (805) should be M=L×F=58 / 1000*130=7.54N.m, set the output torque of the servo motor (805) of the lock reliability test device (8) to be 7.54N.m, and the output force at the lock toggle shaft (809) to be 130N. The moving shaft (809) rotates to open the lock, and the reliab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com