Combined battery string and manufacturing method thereof, and manufacturing method of battery assembly

A combined battery and battery technology, applied in the field of solar cells, can solve the problems of increasing the amount of silver paste on the back, low production efficiency, manual welding, etc., and achieve the effects of improving heat transfer efficiency, increasing density and efficiency, and reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A specific embodiment of the present invention discloses an assembled battery string, the assembled battery string includes a plurality of battery slices and a plurality of conductive connecting devices, and the plurality of conductive connecting devices are respectively located at both ends and in the middle of the assembled battery string for Convergence of combined battery strings and parallel bypass diodes; battery slices and conductive connecting devices are connected by conductive glue.

[0065] Specifically, the conductive connecting device 6 includes a first conductive connecting device 15, a second conductive connecting device 16 and a third conductive connecting device 17; the first conductive connecting device 15 and the second conductive connecting device 16 are respectively located at two terminal, the third conductive connecting device 17 is located between the first conductive connecting device 15 and the second conductive connecting device 16 .

[0066] ...

Embodiment 2

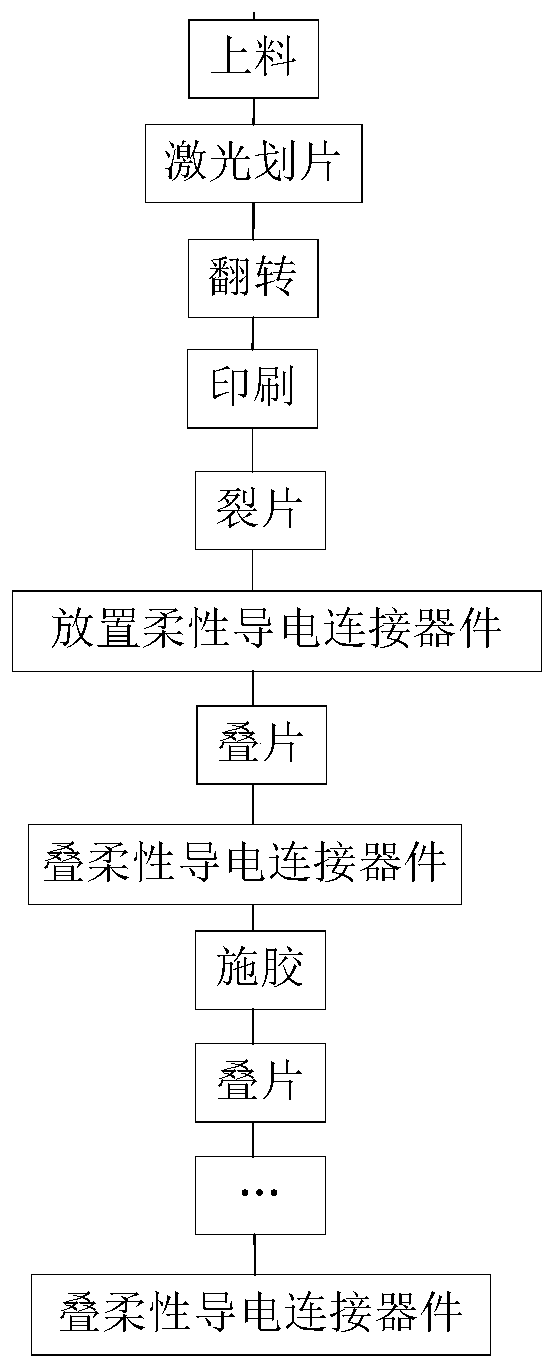

[0078] One embodiment of the present invention discloses a method for preparing a solar cell module, comprising the following steps:

[0079] Step 1: Prepare conductive connection devices and small battery slices;

[0080] Step 2: positioning the first conductive connecting device, and applying conductive glue on the second upper surface of the first conductive connecting device;

[0081] Step 3: Take a small battery slice in step 1 and place it on the first conductive connection device, and the conductive glue corresponds to the back electrode of the small battery slice;

[0082] Step 4: Continue to place small battery slices in series to a certain number;

[0083] Step 5: Apply conductive glue on the first lower surface of the third conductive connection device, the conductive glue corresponds to the front electrode of the front battery sub-slice; apply conductive glue on the second upper surface of the third conductive connection device, take a piece Step 1 The small batt...

Embodiment 3

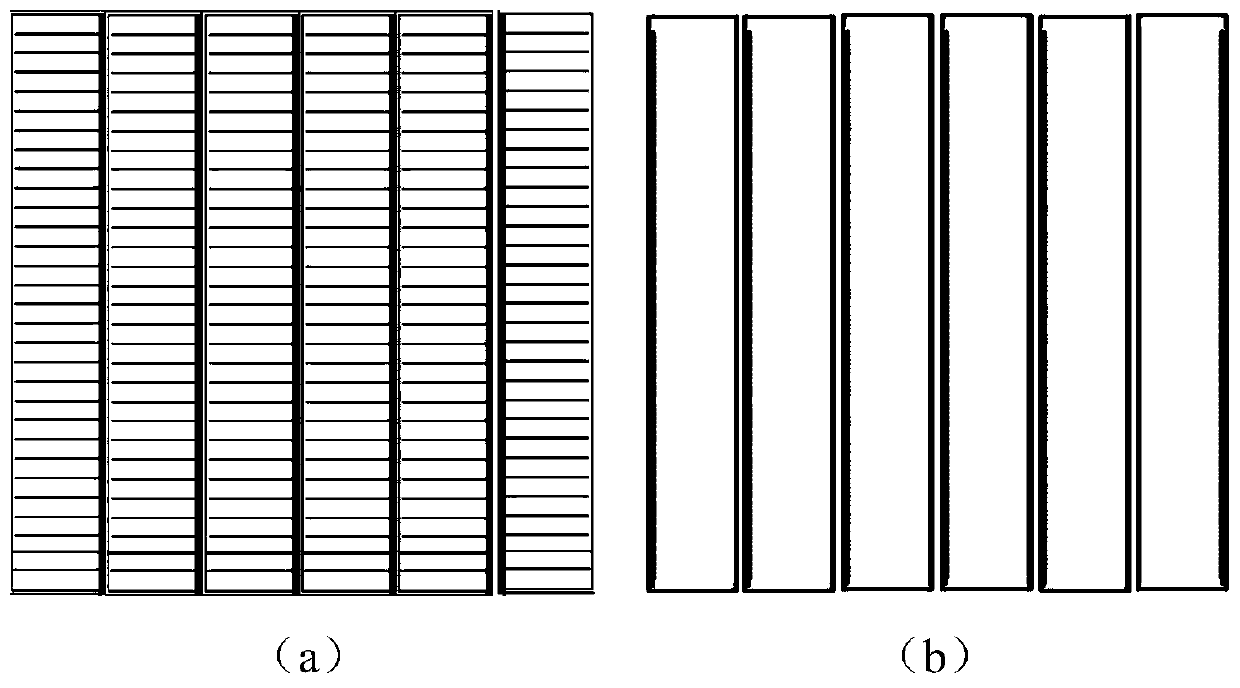

[0103] This embodiment takes 66 pieces of 6-slice battery components as an example to specifically illustrate the preparation of the battery components; figure 1 The main flow chart of the combined battery string for the scheme, figure 2 A schematic diagram of a cell:

[0104] (1) Stretch the tin-coated copper strip with a thickness of 0.08mm and a width of 10mm, and punch it into Figure 4 , and then bend at the bend 7 to obtain a multifunctional flexible conductive connection device 6;

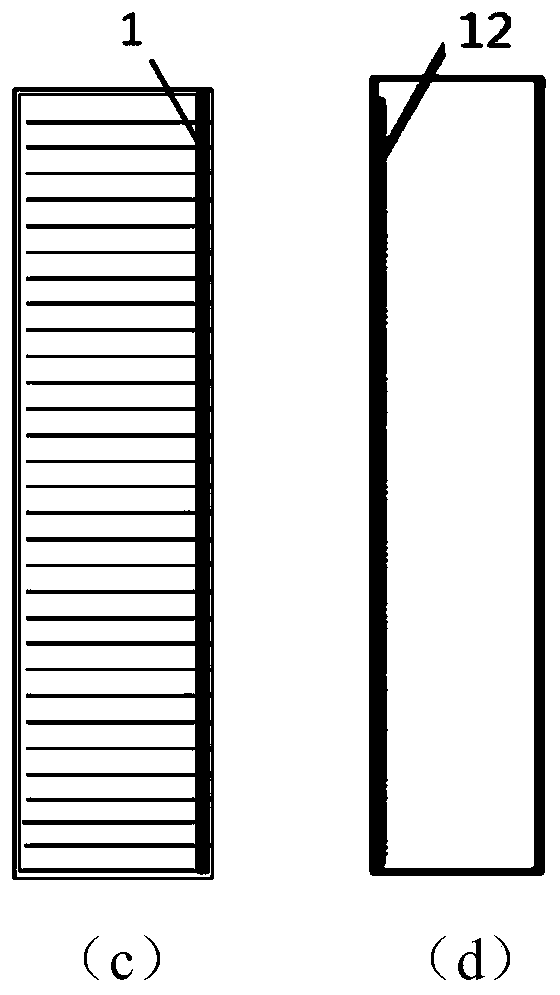

[0105] (2) use figure 2 The battery slices are serially welded, and the complete battery slices are inspected on the front and back, and the printed battery slices that do not meet the standards are removed. After laser cutting on the back, the battery is turned over, and then the conductive adhesive is printed on the front of the battery. battery sheet 2 with conductive glue 9 printed on the front electrode 1;

[0106] (3) The battery sheet 2 that has been laser cut and printed with c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com