Biological fermentation feed capable of relieving piglet anemia, and preparation method for biological fermentation feed

A bio-fermentation feed and piglet technology, applied in the field of enzyme engineering and fermentation engineering, can solve problems such as low immunity, reduced health, piglet anemia, etc., and achieve the effect of increasing hemoglobin content, promoting hematopoiesis, and improving piglet health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

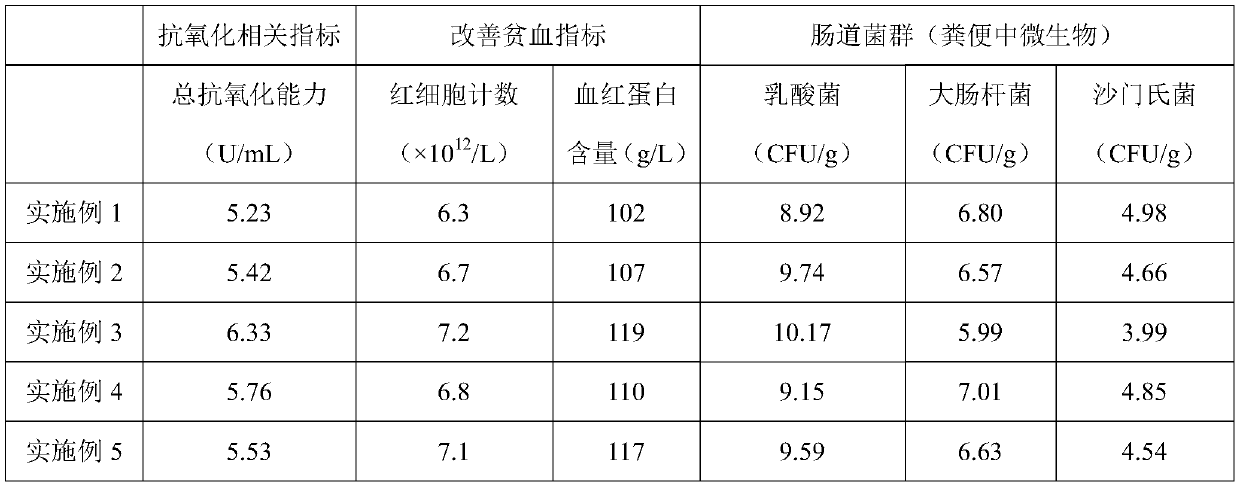

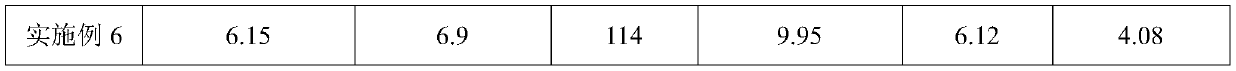

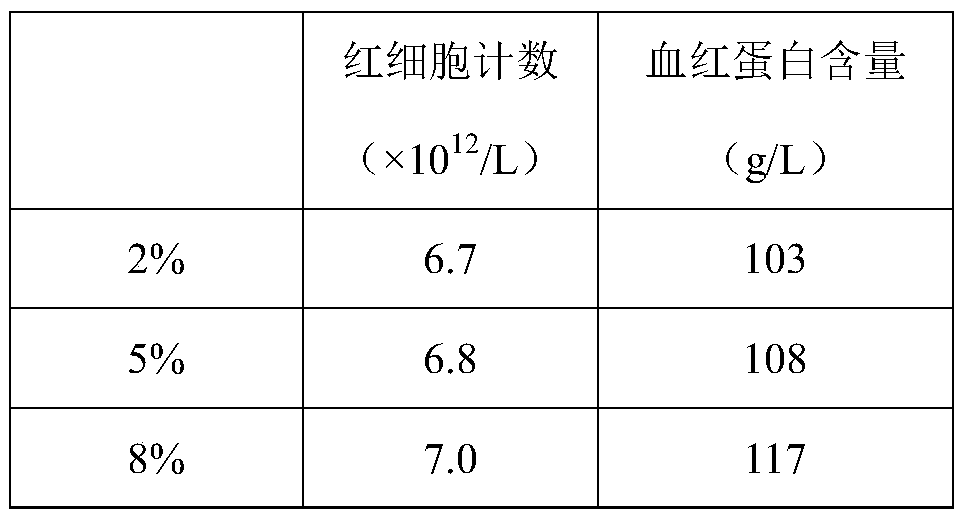

Examples

Embodiment 1

[0030] (1) Preparation of mixed bacterial solution: Bacillus subtilis was cultured in LB medium at 25-35°C for 24 hours to obtain a bacterial concentration of 3×10 8 CFU / mL bacterial liquid; Candida utilis was inoculated in potato culture medium and cultured in a shaker at 25-35°C for 24 hours to obtain a bacterial concentration of 1×10 7 CFU / mL bacterial solution; Inoculate Lactobacillus casei in MRS medium, cultivate in 35-40°C incubator for 48h, and obtain a bacterial concentration of 1×10 9 CFU / mL bacterial solution; inoculate Clostridium butyricum in RCM (enhanced Clostridium medium) medium, and cultivate in an incubator at 35-40°C for 24 hours to obtain a bacterial concentration of 1×10 8 CFU / mL of bacteria solution;

[0031] The prepared bacterial liquid is mixed according to the ratio of Bacillus subtilis: Saccharomyces cerevisiae: Lactobacillus casei: Clostridium butyricum with a concentration ratio of 3:3:2:2 to obtain a mixed bacterial liquid;

[0032] (2) Prepara...

Embodiment 2

[0036] (1) Preparation of mixed bacterial solution: Bacillus subtilis was cultured in LB medium at 25-35°C for 24 hours to obtain a bacterial concentration of 3×10 8 CFU / mL bacterial liquid; Candida utilis was inoculated in potato culture medium and cultured in a shaker at 25-35°C for 24 hours to obtain a bacterial concentration of 1×10 7 CFU / mL bacterial solution; Inoculate Lactobacillus casei in MRS medium, cultivate in 35-40°C incubator for 48h, and obtain a bacterial concentration of 1×10 9 CFU / mL bacterial solution; inoculate Clostridium butyricum in RCM (enhanced Clostridium medium) medium, and cultivate in an incubator at 35-40°C for 24 hours to obtain a bacterial concentration of 1×10 8 CFU / mL of bacteria solution;

[0037] The prepared bacterial liquid is mixed according to the ratio of Bacillus subtilis: Saccharomyces cerevisiae: Lactobacillus casei: Clostridium butyricum with a concentration ratio of 3:3:2:2 to obtain a mixed bacterial liquid;

[0038] (2) The pre...

Embodiment 3

[0042] (1) Preparation of mixed bacterial solution: Bacillus subtilis was cultured in LB medium at 25-35°C for 24 hours to obtain a bacterial concentration of 3×10 8 CFU / mL bacterial liquid; Candida utilis was inoculated in potato culture medium and cultured in a shaker at 25-35°C for 24 hours to obtain a bacterial concentration of 1×10 7 CFU / mL bacterial solution; Inoculate Lactobacillus casei in MRS medium, cultivate in 35-40°C incubator for 48h, and obtain a bacterial concentration of 1×10 9 CFU / mL bacterial solution; inoculate Clostridium butyricum in RCM (enhanced Clostridium medium) medium, and cultivate in an incubator at 35-40°C for 24 hours to obtain a bacterial concentration of 1×10 8 CFU / mL of bacteria solution;

[0043] The prepared bacterial liquid is mixed according to the ratio of Bacillus subtilis: Saccharomyces cerevisiae: Lactobacillus casei: Clostridium butyricum with a concentration ratio of 3:3:2:2 to obtain a mixed bacterial liquid;

[0044] (2) Prepara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com