A mof@pop-n composite catalyst and its preparation method and application

A composite catalyst, mof-74-zn technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the problem of easy poisoning of catalysts and high price of noble metal catalysts , secondary pollution and other issues, to achieve the effect of improved catalytic activity, improved reusability, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Preparation of MOF shell material

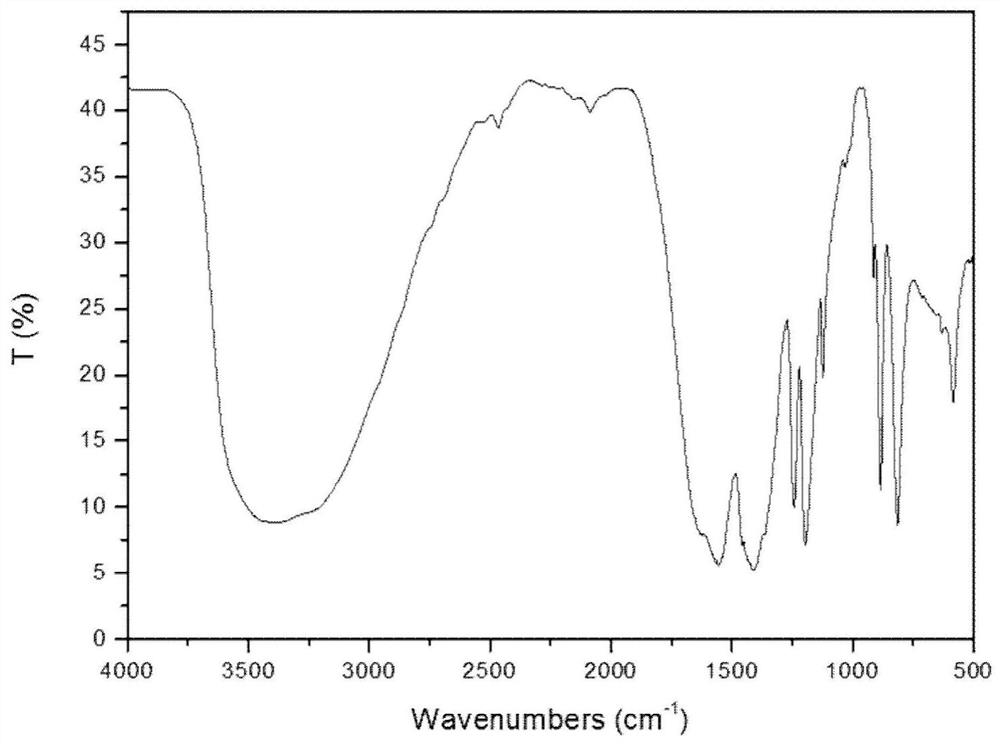

[0029] Preparation of MOF-74-Co: 0.144g 2,5-dihydroxyterephthalic acid and 0.713g Co(NO 3 ) 2 ·H 2 O Sonication Dissolve in 60 mL of a mixture of 1 / 1 / 1 (v / v / v) N,N-dimethylformamide-ethanol-water. Then the clear solution was transferred to a stainless steel autoclave lined with Teflon, and the autoclave was placed in an oven at 100 °C for 24 hours, and the MOF-74-Co was obtained by filtration and centrifugation, and it was tested by FT-IR ( figure 1 ), which is at 3850cm -1 There are characteristic peaks of hydroxyl group, which confirms the successful preparation.

[0030] Preparation of MOF-74-Zn: 2,5-Dihydroxyterephthalic acid (0.5 g, 2.6 mmol) and zinc nitrate (2.0 g, 7.6 mmol) were dissolved in 100 ml DMF with stirring. After the reagents were dissolved, 5 ml of deionized water was added. The solution was transferred to an autoclave lined with Teflon, capped tightly, and placed in an oven at 120°C for 24h. After ...

Embodiment 2

[0031] Example 2 MOF@POP-n composite catalyst

[0032] 1. Preparation of MOF@POP-n composite catalyst

[0033] Put 6.59g of p-dibromobenzyl into 20ml of toluene to obtain solution A, dissolve 4.94g of 1-vinylimidazole in 20ml of toluene to obtain solution B, mix solution A and solution B, and stir at room temperature for 30min to make the stirring uniform. The above solution is at 120 ° C, N 2 Heating under atmosphere for 24 h, cooled to room temperature, and the product was isolated by filtration, and washed with 50 ml of toluene and 50 ml of diethyl ether until the filtrate was colorless. Then the precursor was obtained; 1.06g of the precursor, 487mg of divinylbenzene and 400mg of MOF-74-Co were added to 100ml of N,N-dimethylformamide solution containing 30mg of azobisisobutyronitrile and ultrasonicated for 30min , heated at 150°C for 24h under nitrogen atmosphere, cooled to room temperature, filtered and washed several times with N,N-dimethylformamide, ethanol, ethyl acet...

Embodiment 3

[0038] Example 3 MOF@POP-n composite catalyst

[0039] 1. Preparation of MOF@POP-n composite catalyst

[0040] Put 6.59g of o-benzyl bromide into 20ml of toluene to obtain solution A, dissolve 4.94g of 1-vinylimidazole in 20ml of toluene to obtain solution B, mix solution A and solution B, and stir at room temperature for 30min to make the stirring uniform, Put the above solution at 120 °C N 2Heating under atmosphere for 24 h, cooled to room temperature, and the product was isolated by filtration, and washed with 50 ml of toluene and 50 ml of diethyl ether until the filtrate was colorless. Then, the precursor was obtained; 1.06g of the precursor, 487mg of divinylbenzene and 400mg of MOF-74-Zn were added to 100ml of N,N-dimethylformamide solution containing 30mg of azobisisobutyronitrile and ultrasonicated for 30min. Heated at 150°C under nitrogen atmosphere for 24h, cooled to room temperature, filtered and washed several times with N,N-dimethylformamide, ethanol, ethyl aceta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com