Punching die

A technology for stamping dies and bottom plates, applied in the field of stamping dies, can solve the problems of inconvenient processing of parts, reduce work efficiency, and increase production costs, and achieve the effects of reducing production costs, improving work efficiency, and increasing production volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

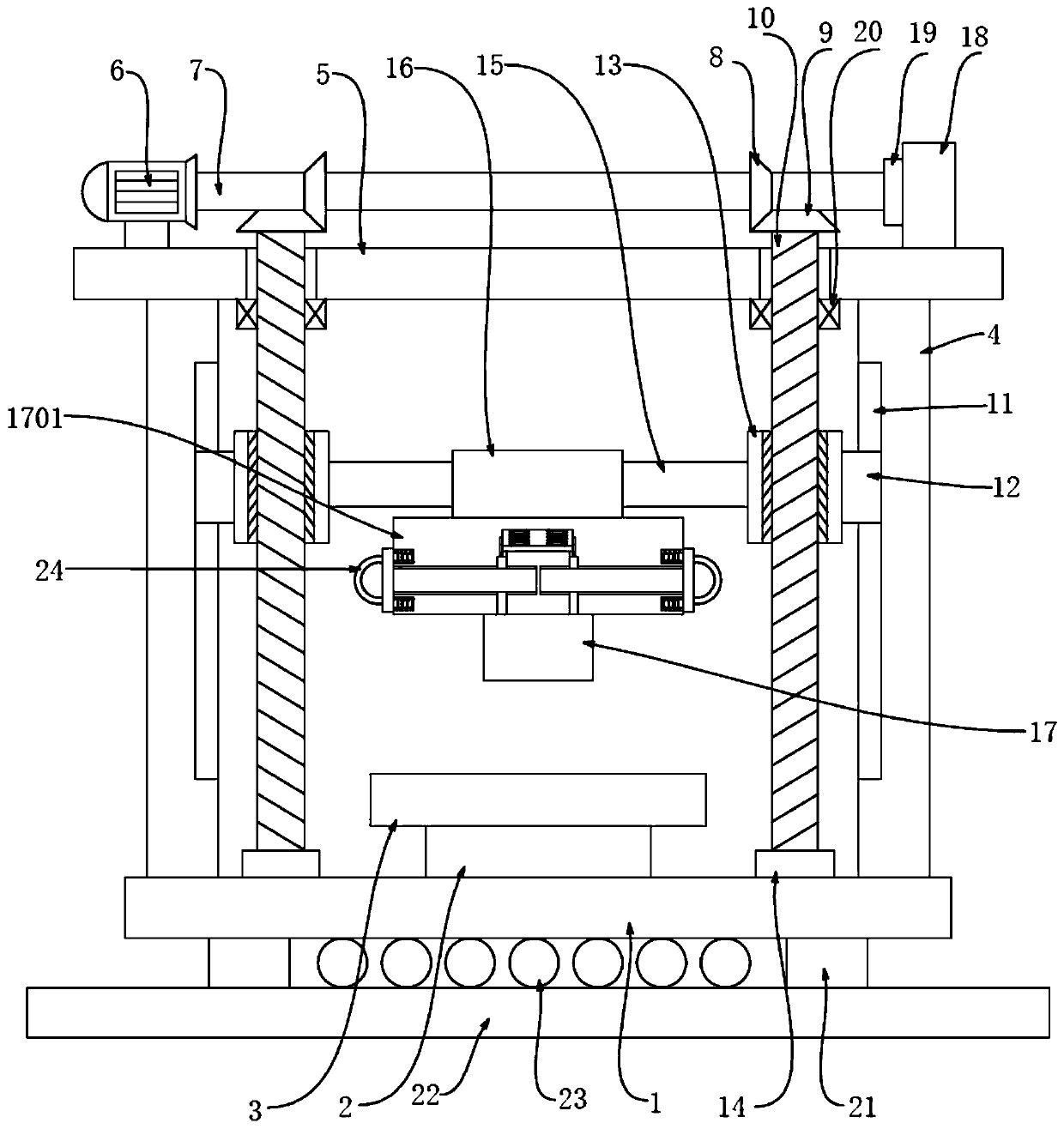

[0023] Put the workpiece on the top of the workbench 3, then start the drive motor 6, the drive motor 6 drives the drive shaft 7 to rotate, the drive shaft 7 drives the first gear 8 to rotate, the first gear 8 drives the second gear 9 to rotate, the second gear 9 Drive the threaded shaft 10 to rotate, because the threaded shaft 10 is threadedly connected with the threaded sleeve 13, and the threaded sleeve 13 is limited by the first slider 12 and the first chute 11, so that the threaded sleeve 13 moves downward on the surface of the threaded shaft 10 , the threaded sleeve 13 drives the stamping die head device 17 to move downward through the sliding rod 15 and the fixing seat 16, so that the stamping head 1702 moves downward to process the workpiece.

Embodiment 2

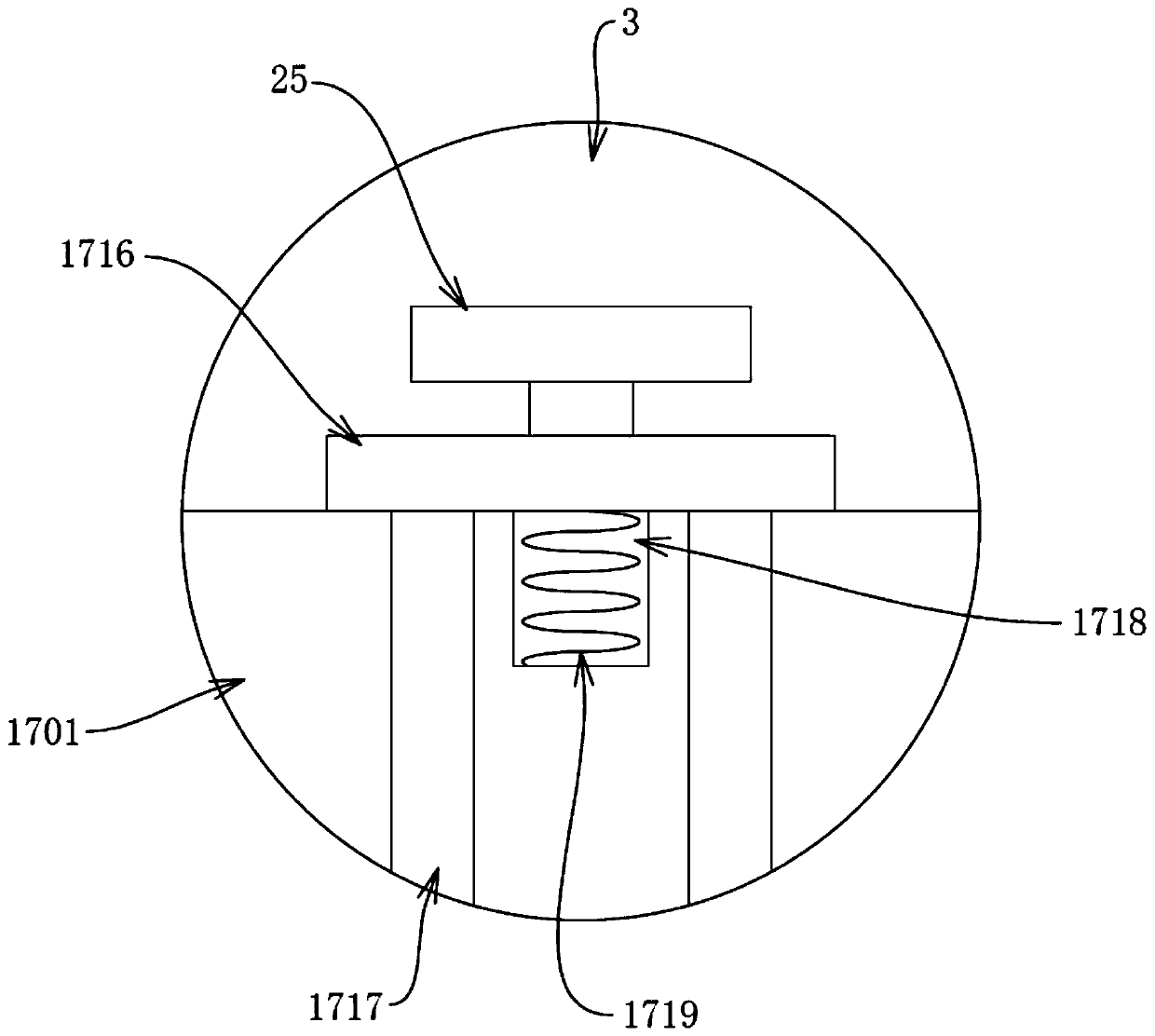

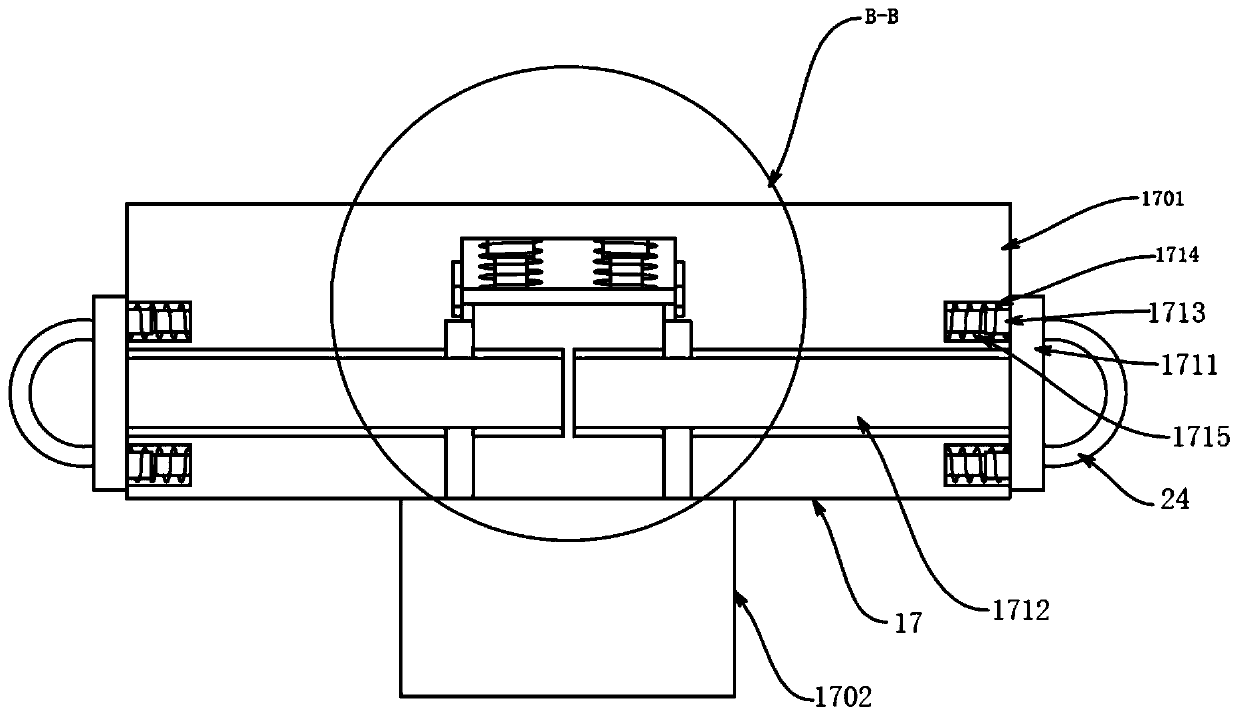

[0025] When the stamping head 1702 breaks down, the second handle 25 drives the clamping block 1716 to move backward, so that the clamping rod 1717 is disengaged from the support block 1710, the third spring 1719 is in a stretched state, and then pulled by the first handle 24 The block 1711 moves to both sides, and the pulling block 1711 drives the second telescopic rod 1713 and the second spring 1715 to move to both sides, the second telescopic rod 1713 and the second spring 1715 are in a stretched state, and the pulling block 1711 drives the stop block 1712 to Move on both sides, so that the limit block 1712 and the support block 1710 are separated from each other. Since the first telescopic rod 1708 and the first spring 1709 are in a compressed state, an elastic force is generated on the support block 1710, so that the support block 1710 drives the stamping head 1702 to move downward. The stamping head 1702 and the fixing groove 1703 are separated from each other, and the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com