Nickel base foil belt brazing material used for high-temperature alloy connection and preparing method and application of nickel base foil belt brazing material

A high-temperature alloy and brazing material technology, which is applied in welding equipment, metal processing equipment, welding/cutting media/materials, etc., can solve problems such as difficulty in realizing the final structure and complexity, and achieve a wide range of brazing temperatures, a wide range of applications, little corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The parent material to be welded in this embodiment is a nickel-based superalloy DD405, and the chemical composition of the alloy is (wt.%):

[0033] Ni-7.5Co-7Cr-5W-6.5Ta-6Al-6.5Ta-3Re-0.15Hf-1.5Mo.

[0034] The solder composition is (wt.%):

[0035] Ni-7Co-10Cr-4Al-3Ti-8W-3Mo-0.3Fe-1Si-1B.

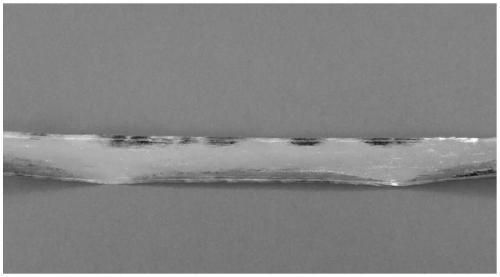

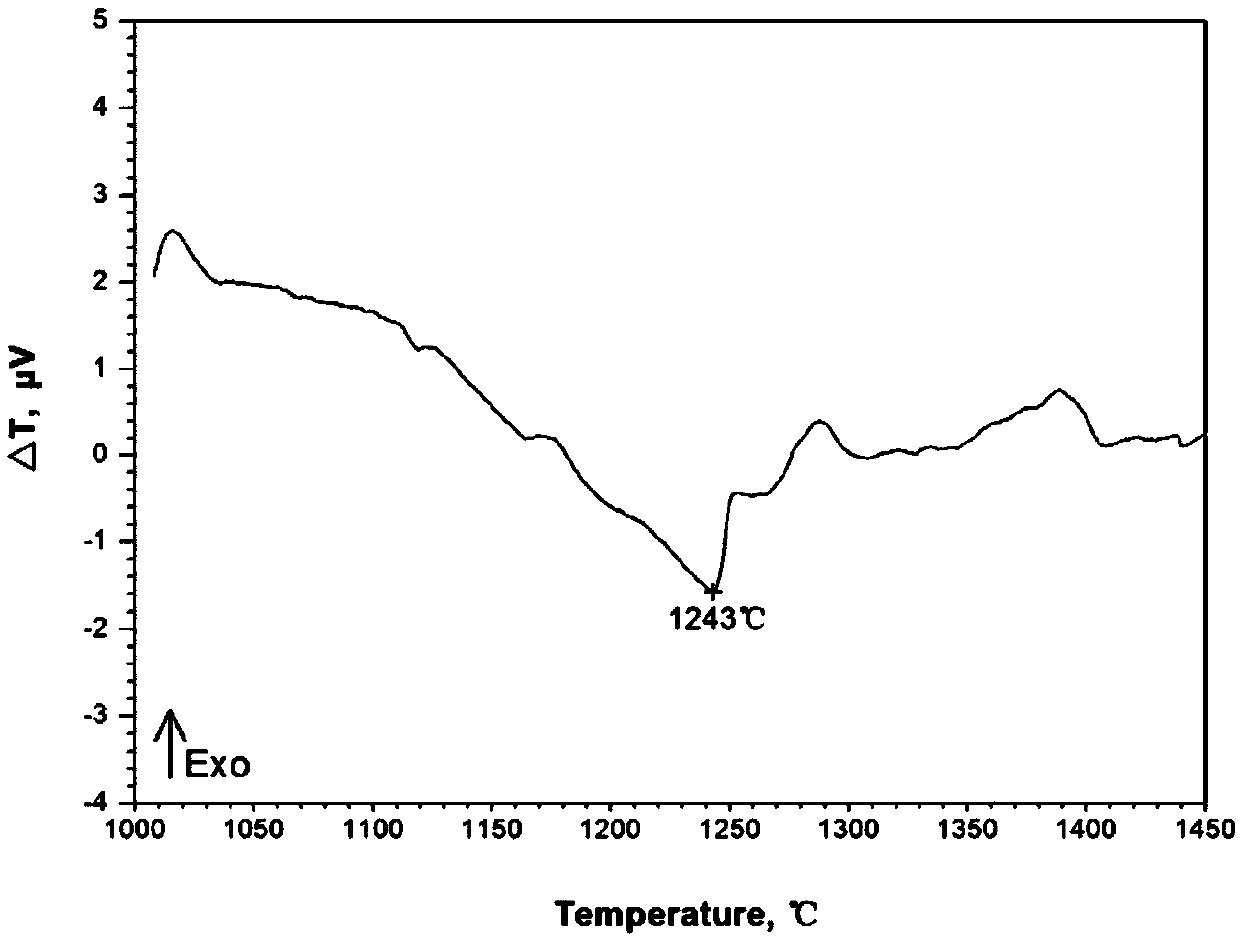

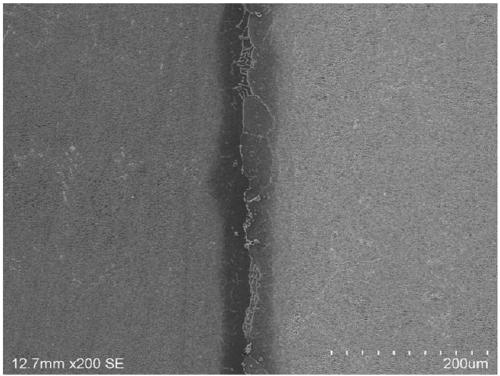

[0036] Brazing material preparation method: mix the raw materials with a purity greater than 99.99% in proportion and put them into a vacuum arc melting furnace to melt them into alloy ingots. The melting process is as follows: refining temperature 1480 ° C, refining time 25 minutes; Melt quick quenching method is used to prepare foil strips. The preparation process is as follows: copper roll speed is 26m / s, injection pressure is 35kPa, and melt temperature is 1480°C. The morphology of the prepared nickel-based foil ribbon solder is as follows: figure 1 As shown, it is band-shaped with a metallic luster on the surface. The DTA curve of foil strip in the present embodiment is a...

Embodiment 2

[0040] The parent material to be welded in this embodiment is a cobalt-based superalloy DZ40M, and the chemical composition of the alloy is (wt.%):

[0041] Co-11Ni-25Cr-7.5W-0.4Ta-1Al-0.2Ti-0.5C-0.2Ti-0.4Mo.

[0042] The chemical composition of solder is (wt.%):

[0043] Ni-16Co-16Cr-3Al-2Ti-8W-5Mo-0.8Fe-3Si-1.5B.

[0044] Brazing material preparation method: mix the raw materials with a purity greater than 99.99% in proportion and put them into a vacuum arc melting furnace to melt them into alloy ingots. The melting process is as follows: refining temperature 1460 ° C, refining time 25 minutes; Melt quick quenching method is used to prepare foil strips, and the preparation process is as follows: copper roll speed is 26m / s, injection pressure is 35kPa, and melt temperature is 1465°C. The prepared nickel-based foil ribbon brazing filler metal is strip-shaped, and the surface presents metallic luster.

[0045] Before welding, the cobalt-based superalloy DZ40M is processed in...

Embodiment 3

[0048] The parent material to be welded in this embodiment is a nickel-based superalloy CMSX-4, and the chemical composition of the alloy is (wt.%):

[0049] Ni-9.5Co-6.5Cr-6.5W-6.5Ta-5.5Al-3Re-1Ti-0.6Mo.

[0050] The chemical composition of solder is (wt.%):

[0051] Ni-6Co-13Cr-2Al-1Ti-4W-4Mo-2Fe-4Si-2B.

[0052] Brazing material preparation method: mix the raw materials with a purity greater than 99.99% in proportion and put them into a vacuum arc melting furnace to melt them into alloy ingots. The melting process is as follows: refining temperature 1420°C, refining time 20 minutes; Melt rapid quenching method is used to prepare foil strips. The preparation process is as follows: copper roll speed 26m / s, injection pressure 35kPa, melt temperature 1440°C. The prepared nickel-based foil ribbon brazing filler metal is strip-shaped, and the surface presents metallic luster.

[0053] Before welding, the solid solution nickel-based superalloy CMSX-4 is processed into Use No. 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com