Ultraviolet-proof transparent high-barrier packaging film and preparation method thereof

An anti-ultraviolet and high-barrier technology, which is applied in packaging, household packaging, and packaged food, can solve the problems of inability to extend food shelf life, high production costs, and low heat-sealing strength, and achieve excellent UV barrier properties and comprehensive production costs. The effect of low cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

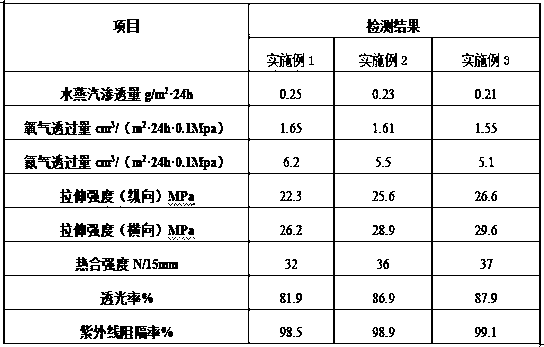

Examples

Embodiment 1

[0037] Example 1: A preparation method of a UV-resistant transparent high-barrier packaging film

[0038] The preparation method of a kind of anti-ultraviolet transparent high-barrier packaging film of the present embodiment comprises the following steps:

[0039] (1) Preparation of attapulgite intercalation modified montmorillonite composite nanofiller:

[0040] At 60°C, disperse attapulgite in water, add 3wt% sodium hexametaphosphate, add 1% modifier of attapulgite mass to the solution, dimethylaminomethacrylate trimethylammonium chloride, Stir and react at 60°C for 1 hour; then add montmorillonite with attapulgite mass of 100 wt% to it, continue stirring for 15 minutes, filter and dry, and attapulgite intercalated modified montmorillonite composite nanofiller is prepared.

[0041]In this process, the ammonium salt cationic groups grafted on the surface of attapulgite are intercalated into the interlayer of montmorillonite by utilizing the cation-exchangeable properties of ...

Embodiment 2

[0047] Example 2: A preparation method of a UV-resistant transparent high-barrier packaging film

[0048] The preparation method of a kind of anti-ultraviolet transparent high-barrier packaging film of the present embodiment comprises the following steps:

[0049] (1) Preparation of attapulgite intercalation modified montmorillonite composite nanofiller:

[0050] At 30°C, disperse the attapulgite in water, add 6wt% sodium hexametaphosphate, and add 1% modifier of attapulgite mass to the solution, dimethylaminomethacrylate trimethylammonium chloride, Stir and react at 60°C for 0.5 hours; then add montmorillonite with attapulgite mass of 150wt% to it, continue stirring for 30 minutes, filter and dry, and attapulgite intercalated modified montmorillonite composite nanofiller is prepared.

[0051] In this process, the ammonium salt cationic groups grafted on the surface of attapulgite are intercalated into the interlayer of montmorillonite by utilizing the cation-exchangeable pro...

Embodiment 3

[0057] Example 3: A preparation method of a UV-resistant transparent high-barrier packaging film

[0058] The preparation method of a kind of anti-ultraviolet transparent high-barrier packaging film of the present embodiment comprises the following steps:

[0059] (1) Preparation of attapulgite intercalation modified montmorillonite composite nanofiller:

[0060] At 55°C, attapulgite was dispersed in water, 5wt% sodium hexametaphosphate was added, and a modifier of attapulgite mass 1% was added to the solution, dimethylaminomethacrylate trimethylammonium chloride, Stir and react at 55°C for 1.2 hours; then add montmorillonite with attapulgite mass of 200wt% to it, continue stirring for 5 minutes, filter and dry, and attapulgite intercalated modified montmorillonite composite nanofiller is prepared.

[0061] In this process, the ammonium salt cationic groups grafted on the surface of attapulgite are intercalated into the interlayer of montmorillonite by utilizing the cation-ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat seal strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com