Nano-silver ion plastic antibacterial master batch and preparation method thereof

A nano-silver ion and antibacterial masterbatch technology, which is applied in the field of nano-silver ion plastic antibacterial masterbatch and its preparation, can solve the problems of yellowing and transparency of products, waste of nano-powder, and reduced antibacterial efficiency, and solve the problems of agglomeration and difficulty in dispersing , Improved dispersibility, high antibacterial efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

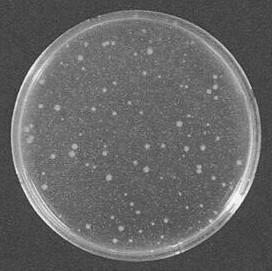

Embodiment 1

[0035] (1) Weigh 6700g of pre-solvent polyethylene glycol, 3300g of paraffin oil, 500g of dispersant triethanolamine, 500g of CYD-DY1800 hydroxyl branching agent, and 250g of zinc stearate stabilizer, put them into the autoclave, start stirring, and the time 30 minutes, drop into 5500g nano-silver ion powder then, continue to keep stirring for 20 minutes. The process settings are as follows: temperature 120°C, pressure 2.8Mp, stirring 150r / min, continuous stirring for 20 minutes to modify, release the pressure and cool down and keep stirring at a low speed for 30 minutes, reduce the pressure to normal pressure, cool to room temperature, and cool and discharge. Nano pre-dispersed silver paste;

[0036] (2) According to the mass ratio of 40:80, the nano pre-dispersed silver paste and plastic polyethylene 1I2A are plasticized and granulated through a 65-type parallel twin-screw extruder, and the pre-dispersed silver paste is injected into the twin-screw from the middle feeding po...

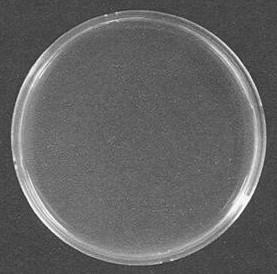

Embodiment 2

[0038] (1) Weigh 5000g of pre-solvent polyethylene glycol, 500g of dispersant triethanolamine, 500g of CYD-DY1800 hydroxyl branching agent, and 500g of zinc stearate stabilizer, put them into the autoclave, start stirring, stir for 30 minutes, and then Drop into 3500g nano-silver ion powder, continue to keep stirring for 10 minutes. The process settings are as follows: temperature 120°C, pressure 3Mp, stirring 50r / min, continuous stirring for 10 minutes to modify, release the pressure and cool down and keep stirring at a low speed for 30 minutes, reduce the pressure to normal pressure, cool to room temperature, and cool the material to obtain nano Pre-dispersed silver paste;

[0039] (2) According to the mass ratio of 20:80, the nano pre-dispersed silver paste and plastic polyethylene 1I2A are plasticized and granulated through a 65-type parallel twin-screw extruder, and the pre-dispersed silver paste is injected into the twin-screw from the middle feeding port to obtain Anti...

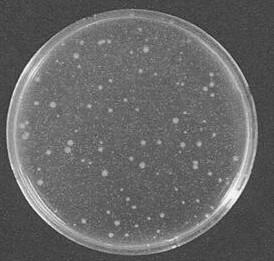

Embodiment 3

[0041] (1) Weigh 12000g of pre-solvent paraffin oil, 400g of dispersant triethanolamine, 600g of CYD-DY1800 hydroxyl branching agent, 600g of zinc stearate stabilizer, put them into the autoclave, start stirring, stir for 45 minutes, and then put 5000g Nano silver ion powder, continue to keep stirring for 30 minutes. The process settings are as follows: temperature 120°C, pressure 2.8Mp, stirring 150r / min, continuous stirring for 30 minutes to modify, release pressure and cool down and keep stirring at low speed for 30 minutes, reduce pressure to normal pressure, cool to room temperature, and cool and discharge. Nano pre-dispersed silver paste;

[0042] (2) According to the mass ratio of 30:70, the nanometer pre-dispersed silver paste and plastic styrene AS are plasticized and granulated through a 65-type parallel twin-screw extruder, and the pre-dispersed silver paste is injected into the twin-screw from the middle feeding port to obtain Antibacterial masterbatch for styrene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com