Thermoplastic polyurethane elastomer composition, preparation method and applications thereof

A thermoplastic polyurethane and elastomer technology, applied in the field of thermoplastic polyurethane elastomer composition and its preparation, can solve problems such as poor compatibility and decreased mechanical strength of materials, and achieve excellent wear resistance, excellent mechanical properties, and a wide range of hardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

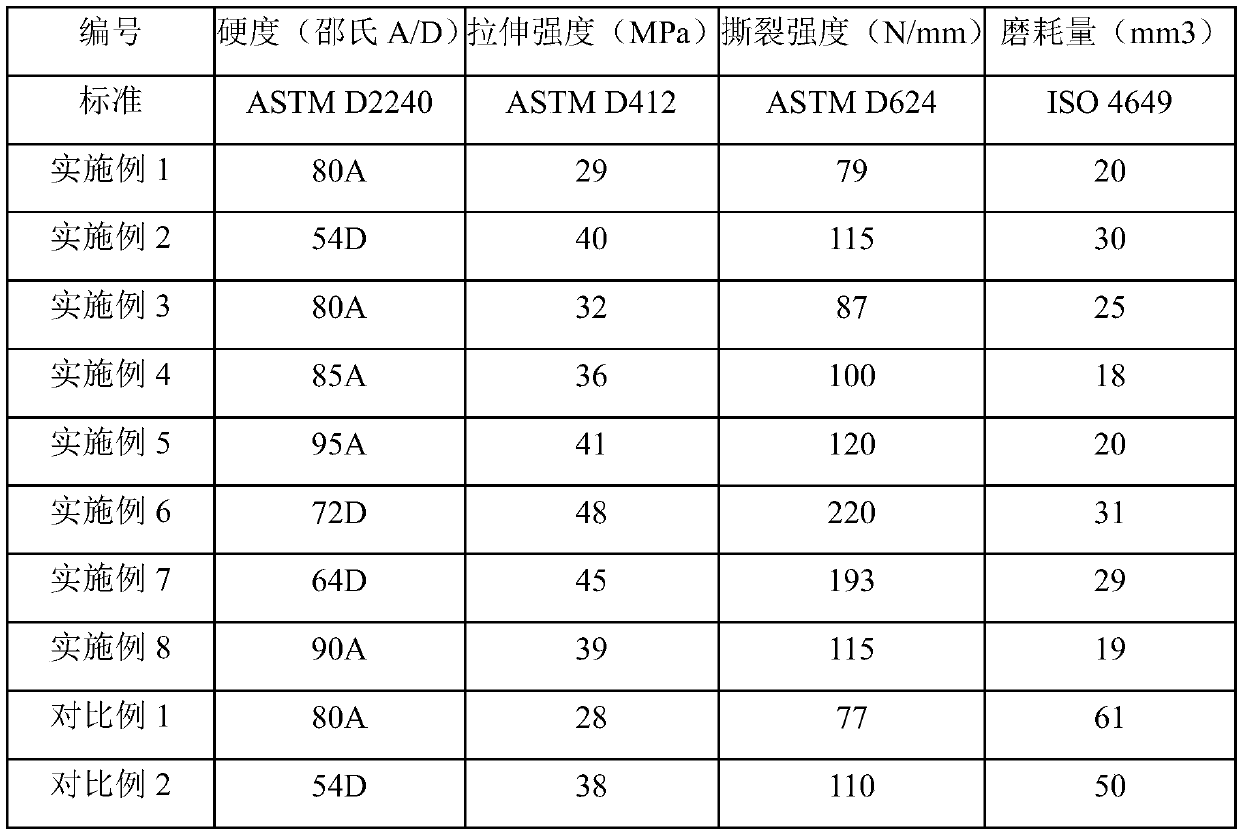

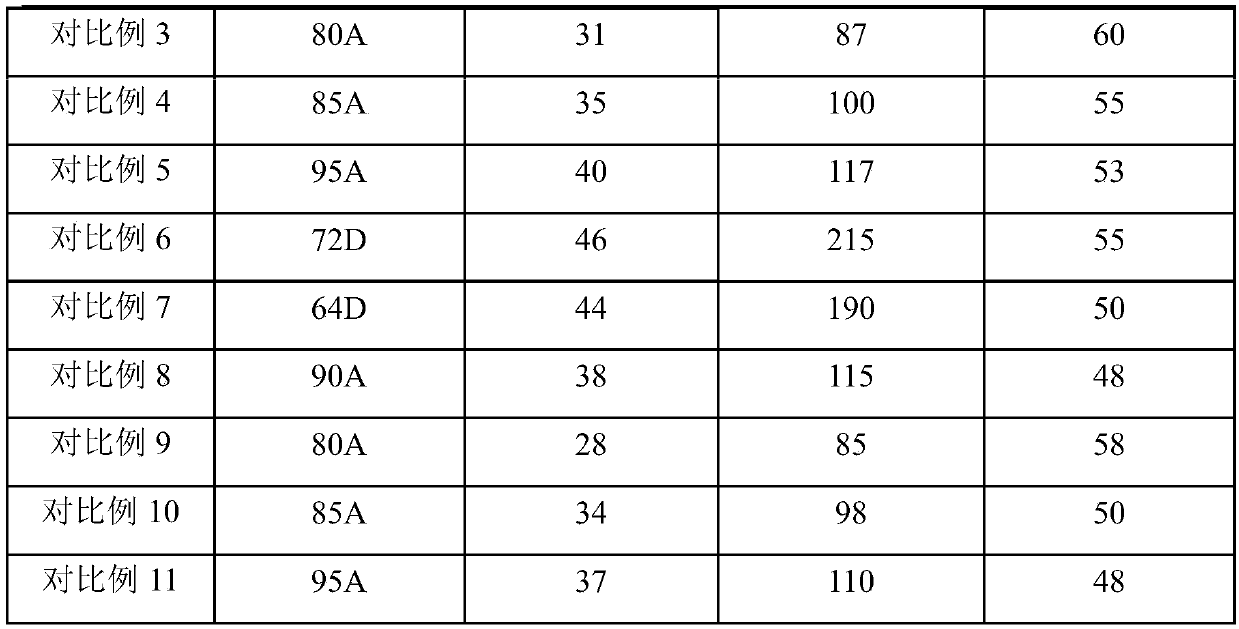

Examples

Embodiment 1

[0043] The olefin polymer is ethylene-α-olefin copolymer, and the addition amount is 5 parts. The ethylene content in the ethylene-α-olefin copolymer is 45 wt%, the α-olefin is propylene, and the melt index (ASTM D1238, 190°C / 2.16kg) is 0.5g / 10min (purchased from China Petroleum and Chemical Corporation, the trade mark is EP J0010 ). As the hyperbranched polymer, hyperbranched polyamide was selected, the addition amount was 5 parts, and the molecular weight was 350 g / mol (purchased from Wuhan Hyperbranched Resin Technology Co., Ltd., brand name is HyPer N101).

[0044] Mix the above two with 90 parts of polyether thermoplastic polyurethane elastomer (commercially available) with a hardness of 80A on a high-speed mixer, and melt, blend and extrude the mixture on an extruder with an extrusion temperature of 160-180°C The wear-resistant TPU composition is obtained.

Embodiment 2

[0046] The olefin polymer is selected from ethylene-α-olefin copolymer, and the addition amount is 25 parts. The ethylene content in the ethylene-α-olefin copolymer is 90wt%, the α-olefin is 1-octene, and the melt index (ASTM D1238, 190°C / 2.16kg) is 30g / 10min (purchased from Japan Mitsui Chemicals, the brand is DF 903) . The hyperbranched polymer is hyperbranched polyamidoamine, the addition amount is 5 parts, and the molecular weight is 116000 g / mol (purchased from Weihai Chenyuan Molecular New Material Co., Ltd., brand name is CDY-170A).

[0047] It is mixed with 70 parts of polyester thermoplastic polyurethane elastomer (commercially available) with a hardness of 54D on a high-speed mixer, and the mixture is melt-blended and extruded on an extruder with an extrusion temperature of 195-210°C to obtain Abrasion resistant TPU composition.

Embodiment 3

[0049] The olefin polymer is ethylene-vinyl ester copolymer, and the addition amount is 5 parts. The ethylene content in the ethylene-vinyl monomer copolymer is 60wt%, the vinyl monomer is vinyl acetate, and the melt index (ASTM D1238, 190°C / 2.16kg) is 50g / 10min (purchased from China Petrochemical Corporation, trade mark for 165E). The hyperbranched polymer is selected from hyperbranched epoxy resin, the addition amount is 25 parts, and the molecular weight is 3200g / mol (purchased from Wuhan Hyperbranched Resin Technology Co., Ltd., brand name is HyPerE102).

[0050] It is mixed with 70 parts of polyester thermoplastic polyurethane elastomer (commercially available) with a hardness of 80A on a high-speed mixer, and the mixture is melt-blended and extruded on an extruder with an extrusion temperature of 160-185°C to obtain Abrasion resistant TPU composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com