A carbon dioxide corrosion resistant seamless steel pipe and its preparation method

A seamless steel pipe and carbon dioxide technology, applied in the field of pipeline steel manufacturing, can solve problems such as early corrosion failure, high cost, and shortened service life of pipelines, and achieve good corrosion resistance and economy, excellent carbon dioxide corrosion resistance, and low cost low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

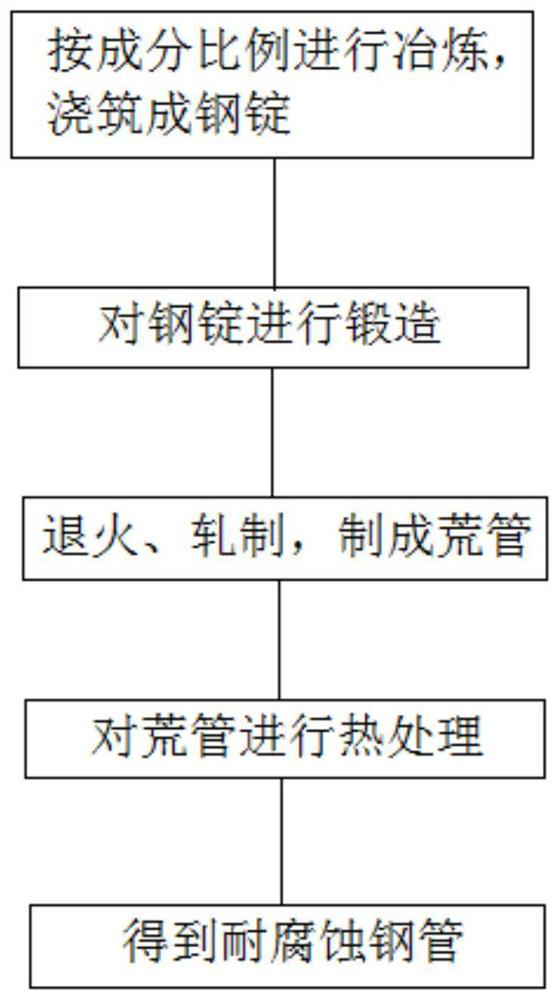

[0037] Prepare the preparation method of above-mentioned carbon dioxide corrosion resistant seamless steel pipe, such as figure 1 As shown, the steps include:

[0038] Step 1, smelting and pouring steel ingots according to the composition of the above-mentioned seamless steel pipe;

[0039] Step 2. After smelting, the steel billet needs to be forged. The characteristics are: the heating temperature is not less than 1150°C, followed by forging, and the forging billet is annealed after forging. The temperature is 800-900°C, and the holding time is set at 3-5min / mm, cooling rate≤30℃ / h;

[0040] Step 3. Tube rolling process after forging, which is characterized in that: after forging, the round billet is annealed at 650-750°C, the annealing process is heat preservation in the furnace for 3-4 hours, and the annealed tube billet is heated at 1150-1200°C for 1.5-1.5 hours After 2 hours, use a conical piercer to perforate, and then pass through a sizing machine or a stretching and ...

Embodiment 1

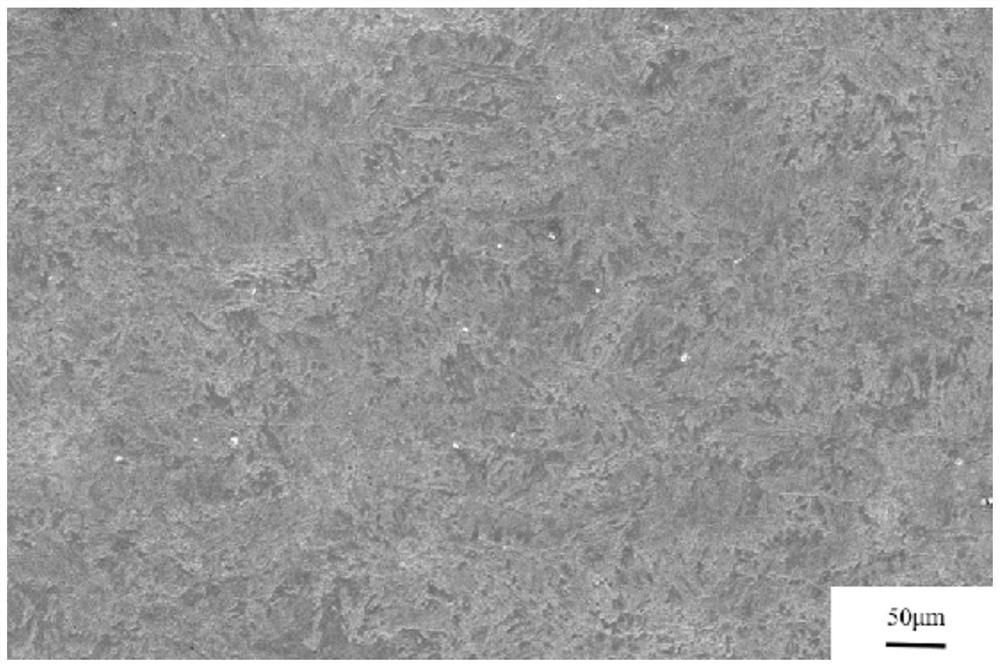

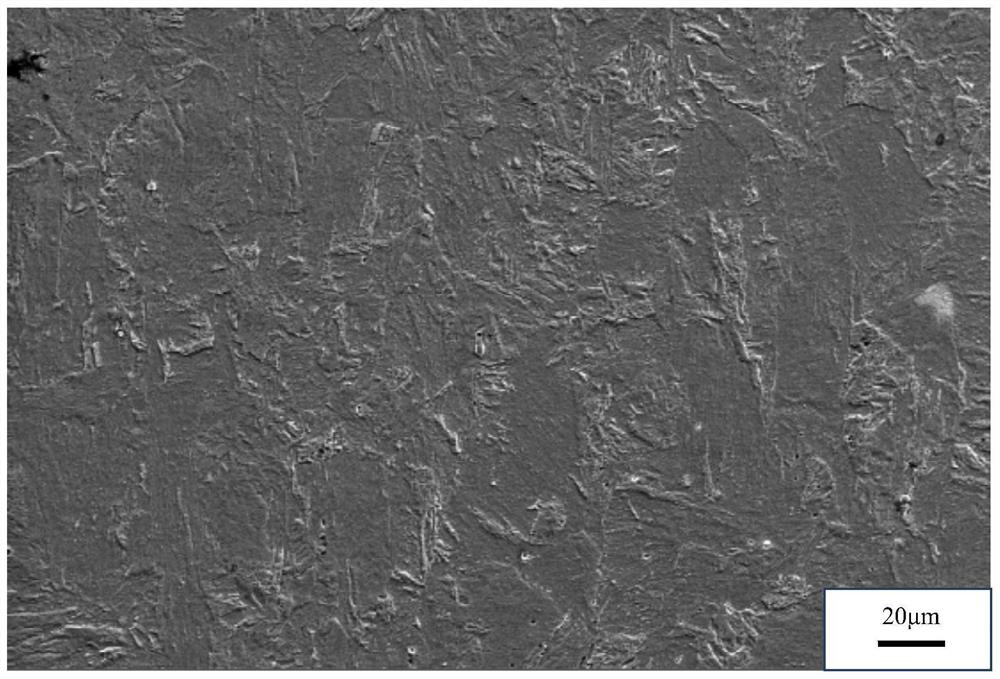

[0069] The microstructure and morphology of the seamless steel pipe prepared in embodiment 1 and embodiment 2 are as follows: figure 2 and image 3 shown. As can be seen from the figure, in Example 1, the Cr content is close to the lower limit, and the Ni content is close to the upper limit. In Example 2, the Cr content is close to the upper limit, and the Ni content is close to the lower limit. near the endpoint. The structures of the two examples are both bainite + a small amount of ferrite, the structure is uniform, there is no obvious inclusion, and the comprehensive mechanical properties and corrosion resistance are good, which also shows that the present invention can achieve the expected effect within the composition range of the application.

[0070] Compared with the prior art, the beneficial effects of the present invention are as follows:

[0071] Since Cr and C in steel are easy to form Cr carbides, adding Cr to carbon steel alone cannot achieve the expected co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com