Rapid pre-warming starting system and method for power plant steam turbine

A start-up system and steam turbine technology, applied to the start of the engine, engine components, machines/engines, etc., can solve the problems of power plant unit energy efficiency reduction, long duration, complicated operation, etc., to reduce warm-up time and start-up time , Improve the effect of preheating steam flow and temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

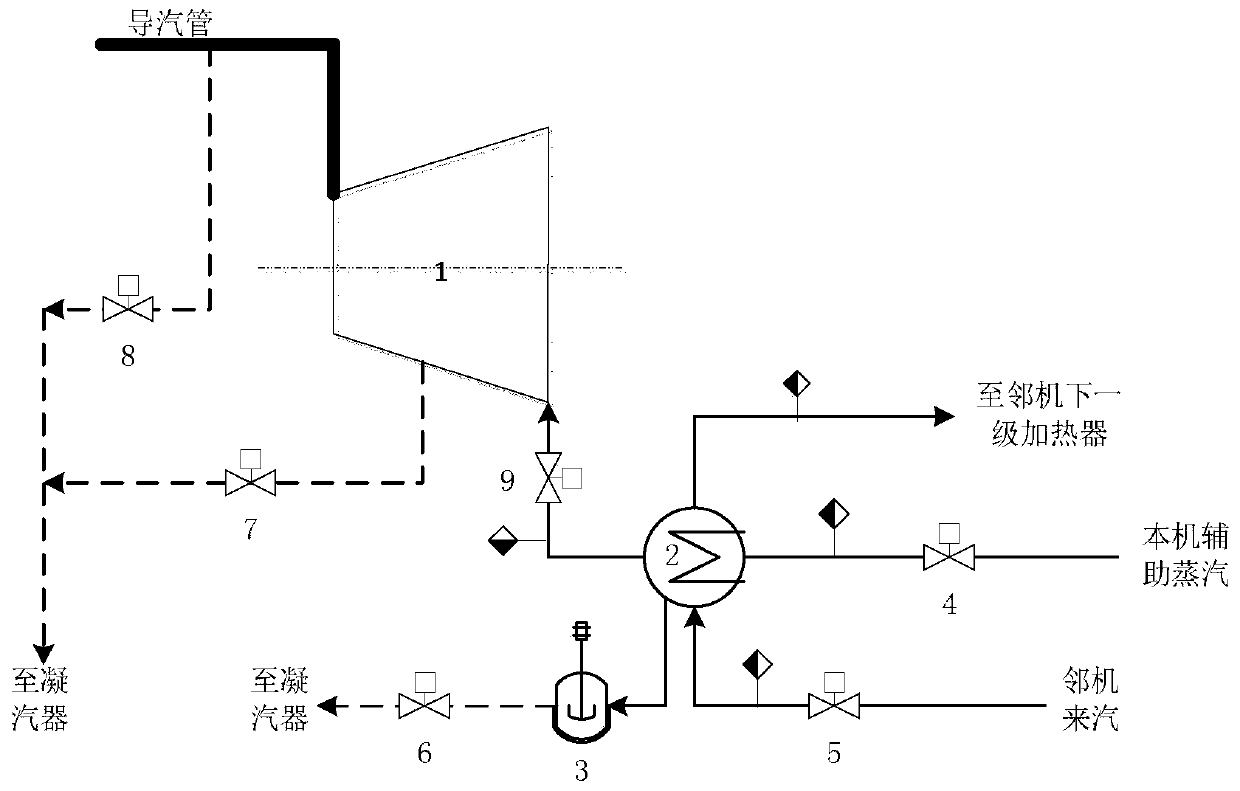

[0042] see figure 1 , is an embodiment of the rapid warm-up start-up system for a steam turbine in a power plant according to the present invention. The steam turbine in a power plant includes at least one running adjacent machine and a local machine that needs to be quickly warm-up started.

[0043] The machine includes a high-pressure cylinder 1, one of which is connected to the heater 2 through a steam pipeline and a steam inlet control valve 9; Output to the local condenser; the third is also connected to the local condenser after the exhaust pipe and the warm cylinder exhaust control valve 7.

[0044] The heater 2 also enters the incoming steam of the adjacent machine through the steam pipeline and the steam source control valve 5 of the heating source; the auxiliary steam of the machine is input through the steam pipeline and the steam control valve 4; and is output to the next stage of the adjacent machine through the steam pipeline Heater; it is output to the drain ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com