Pressure sensor calibration device

A technology of pressure sensor and calibration device, which is applied in the direction of measuring device, calibration/testing of force/torque/power measuring instrument, and measurement of fluid pressure. Simple, overcoming oversized effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

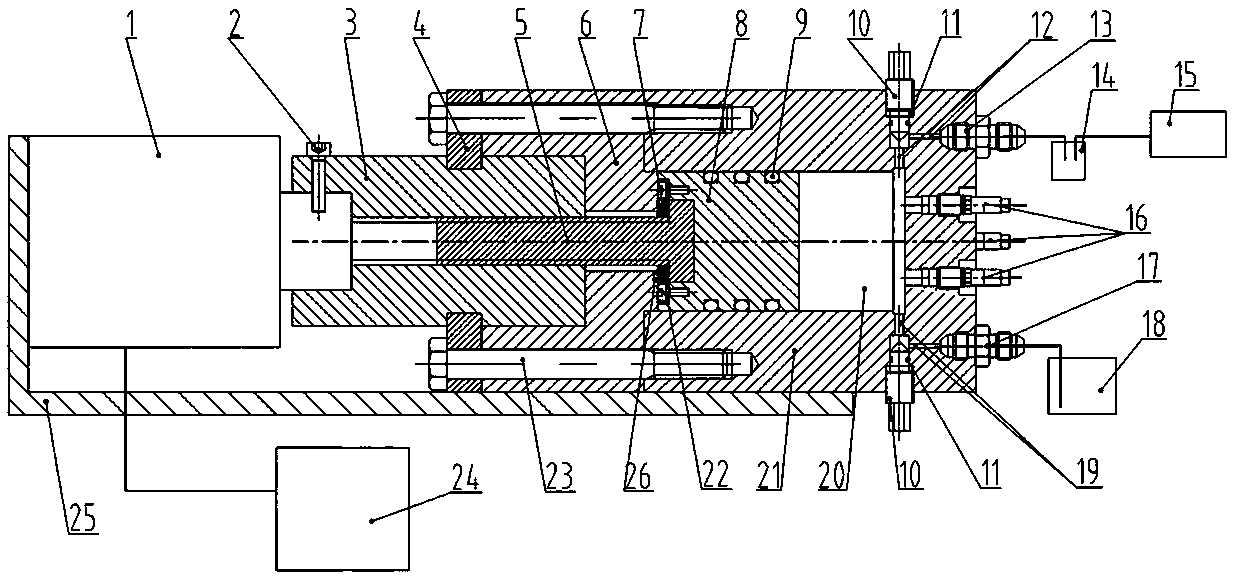

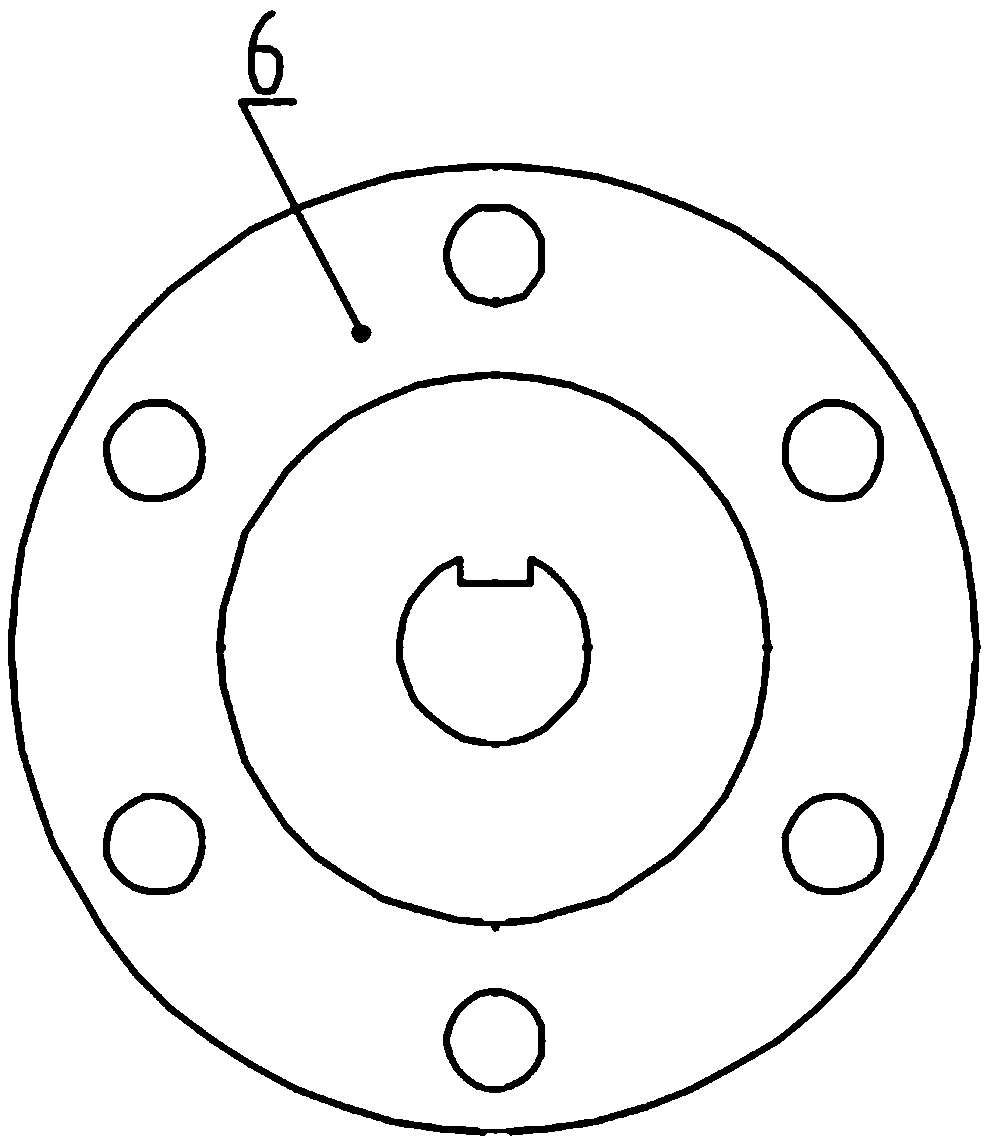

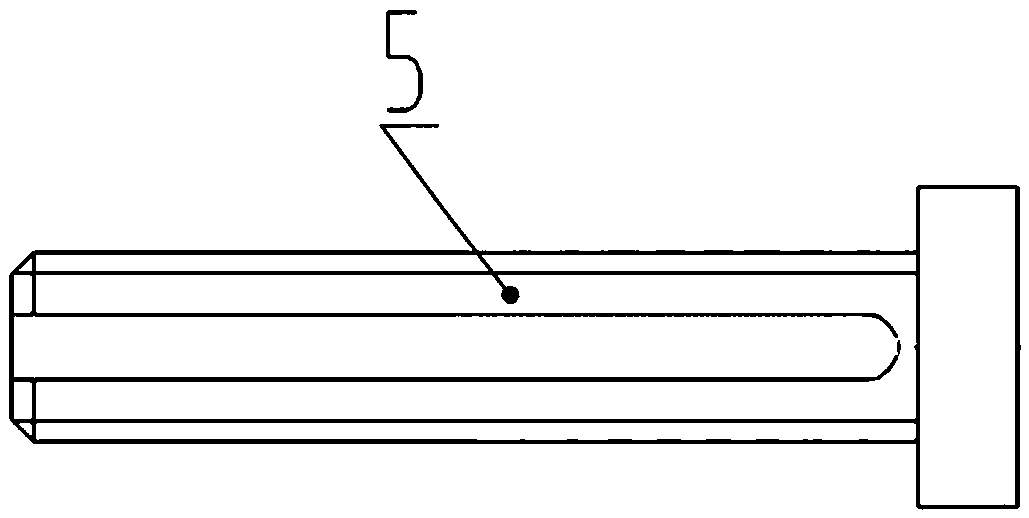

[0022] A pressure sensor calibration device, including a stepping motor 1, a transmission nut 3, a nut limit plate 4, a transmission screw 5, a cylinder head 6, a piston 8, a sealing valve 10, an oil return cylinder 14, a vacuum pump 15, a pressure sensor 16, Fuel tank 18, cavity 21, control box 24.

[0023]The drive nut 3 is cylindrical, with an internal thread in its center. The nominal size of the internal thread is consistent with the nominal size of the thread on the drive screw 5, and the two form a helical pair transmission mechanism; the left end of the drive nut 3 has a light hole, the diameter of the light hole and the step The shaft head of the motor 1 has a clearance fit, and the two are rigidly fixed together by the anti-rotation bolt 2 to realize axial and circumferential positioning; the outer cylinder of the drive nut 3 is provided with an annular groove for installing the nut limiter plate 4, and the nut limiter The position plate 4 only limits the axial movem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com