MEMS microphone

A microphone and ASIC chip technology, which is applied in the field of MEMS microphones, can solve problems such as short circuit, breakdown open circuit, etc., and achieve the effect of improving reliability, avoiding open circuit or short circuit, and improving dustproof function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

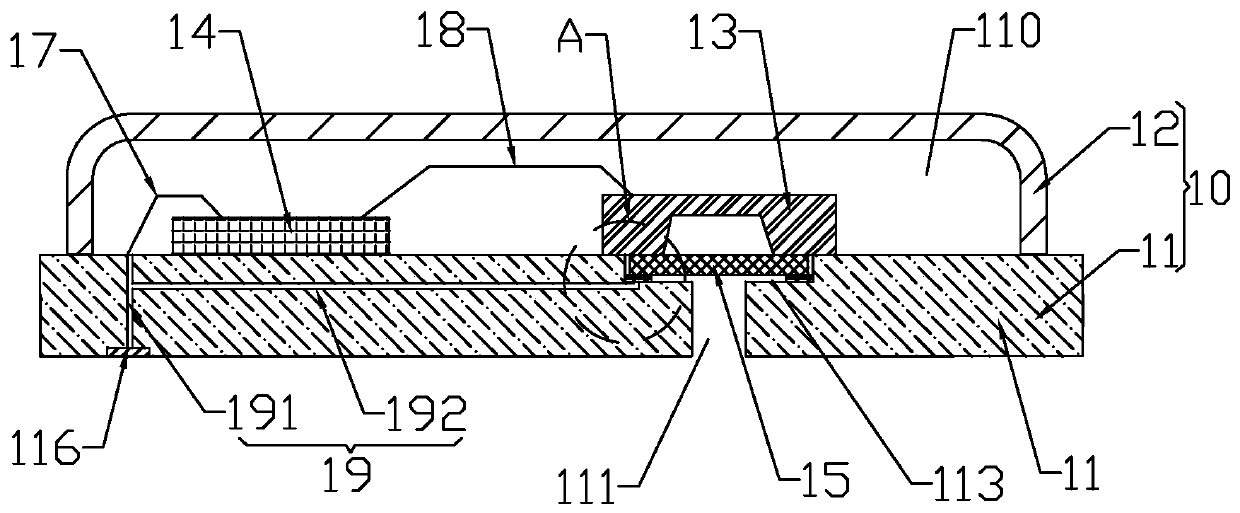

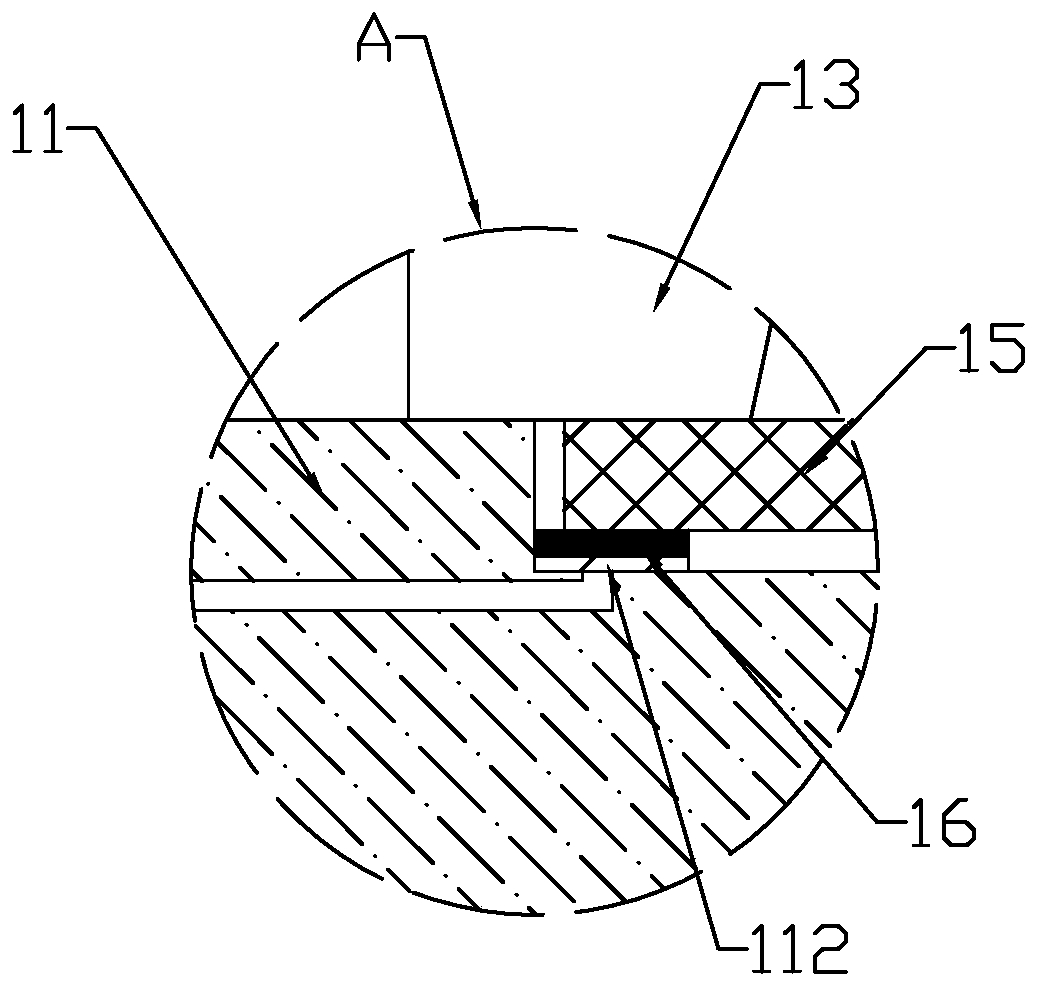

[0028] see Figure 1-2 , a kind of MEMS microphone of the present embodiment, comprises the housing 10 that has encapsulation cavity 110 and is installed in the MEMS chip 13 and ASIC chip 14 in the encapsulation cavity 110, and housing 10 comprises for installing MEMS chip 13 and ASIC chip The substrate 11 of 14 and the housing 12 surrounding the package cavity 110 with the substrate 11, the microphone also includes a first metal lead 17 electrically connecting the ASIC chip 14 and the substrate 11 and a second metal lead 17 electrically connecting the ASIC chip 14 and the MEMS chip 13. Lead wire 18, substrate 11 is provided with acoustic through-hole 111, and MEMS microphone also comprises the conductive dust-proof net 15 that is covered in acoustic through-hole 111 near the end of MEMS chip 13, and conductive dust-proof net 15, is fixed with conductive dust-proof net 15 The connected first ground pad 112, the first ground pad 116 provided on the outer surface of the substrat...

no. 2 example

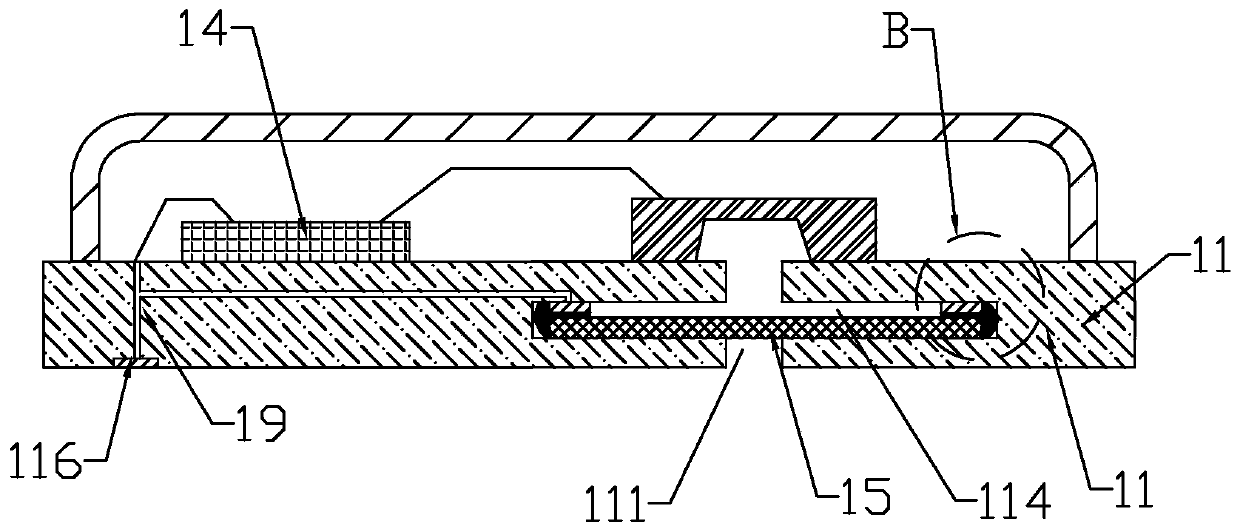

[0037] see further Figure 3-4 , different from the first embodiment, the conductive dust-proof net 15 in this embodiment is fixed inside the substrate 11 . Specifically, a second installation groove 114 for accommodating the conductive dust-proof net 15 is provided between the inner surface and the outer surface of the substrate 11 , and the conductive dust-proof net 15 covers the middle position of the acoustic through hole 111 .

[0038] The MEMS microphone of the present embodiment improves the dust-proof function of the microphone by covering the conductive dust-proof net 15 on the acoustic through hole 111; A grounding pad 112 and the conduction of the first grounding pad 116, the ASIC chip 14 is electrically connected to the first metal lead 17, and the first metal lead 17 guides the static electricity in the ASIC chip 14 from the first The ground pad 116 is introduced into the ground layer of the external circuit of the terminal equipment, and the first ground pad 112...

no. 3 example

[0041] see further Figure 5-6 Different from the first embodiment and the second embodiment, the conductive dust-proof net 15 is arranged on the surface of the substrate 11 away from the MEMS chip 13, and the second grounding pad electrically connected to the conductive dust-proof net 15 is provided on the substrate 11 117 and the metal conductive member 19 electrically connecting the first metal lead 17 and the second ground pad 117, and the conductive dust filter 15 is electrically connected to the ground terminal of the external circuit.

[0042] It should be noted that the outer surface of the substrate 11 is provided with a first installation groove 113 for accommodating the conductive dust filter 15 , and the conductive dust filter 15 covers the end of the acoustic through hole 111 away from the MEMS chip 13 . The conductive dust-proof net 15 is arranged on the outer surface of the substrate 11, and the outer surface of the conductive dust-proof net 15 is at the same le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com