Dustproof, antibacterial and anti-virus coating as well as preparation method and application thereof

An anti-virus and paint technology, applied in anti-fouling/underwater paint, coating, cooling/ventilation/heating renovation, etc., can solve the problems of simple principle and poor effect, avoid dust adsorption, reduce bacteria and fungi, etc. The effect of breeding, good antibacterial and antiviral properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

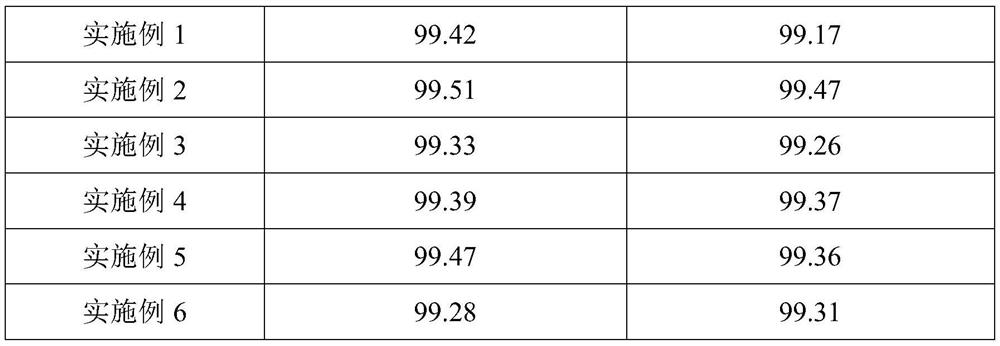

Examples

Embodiment 1

[0023] Step 1: Disperse 98g of Shin-Etsu silicone resin KR400 in the flask, then add 2g of perfluorooctyltrimethoxysilane and 0.5g of KH550 into the flask, stir while raising the temperature to 60°C, and get Fluorosilane modified silicone resin.

[0024] The second step: add 0.4g nano-ATO (particle size is 20nm), 0.2g polytetrafluoroethylene microspheres (particle size is 0.5μm) and 0.3g nano-silver solution to the fluorosilane modified silicone resin solution to obtain a mixed solution .

[0025] Step 3: Stir the above-mentioned fluorosilane-modified silicone resin solution containing various additives under a high-speed shearing machine (rotation speed is 4000rpm), and apply ultrasonic treatment (ultrasonic power is 100W, ultrasonic frequency is 30kH) 30 minutes to get long-lasting dust-proof, anti-bacterial and anti-virus coatings.

[0026] Step 4: Coat the coating on the surface of 5G electronic product heat dissipation equipment by spraying and showering. In a normal te...

Embodiment 2

[0028] Step 1: Disperse 95g of Shin-Etsu silicone resin KR400 in the flask, then add 5g of perfluorooctyltriethoxysilane and 0.2g of KH570 into the flask, stir while raising the temperature to 60°C, after 2 hours A fluorosilane-modified silicone resin was obtained.

[0029] The second step: add 0.3g nano-ITO (particle size is 20nm), 0.3g polytetrafluoroethylene microspheres (particle size is 0.5μm) and 0.2g nano-copper solution to the fluorosilane modified silicone resin solution to obtain a mixed solution .

[0030] Step 3: Stir the above-mentioned fluorosilane-modified silicone resin solution containing various additives under a high-speed shearing machine (3000 rpm), and apply ultrasonic treatment (ultrasonic power 90W, ultrasonic frequency 30kH) 40 minutes to get long-lasting dust-proof, anti-bacterial and anti-virus coatings.

[0031] Step 4: Coat the coating on the surface of 5G electronic product heat dissipation equipment by spraying and showering. In a normal temper...

Embodiment 3

[0033] Step 1: Disperse 90g of Shin-Etsu silicone resin KR400 in the flask, then take 10g of perfluorodecyltrimethoxysilane and 0.6g of KH550 into the flask, stir while raising the temperature to 60°C, and get Fluorosilane modified silicone resin.

[0034] The second step: add 0.2g nano-ATO (particle size is 20nm), 0.1g polyvinylidene fluoride microspheres (particle size is 0.5μm) and 0.4g quaternary ammonium salt solution to the fluorosilane modified silicone resin solution to obtain mixture.

[0035] Step 3: Stir the above-mentioned fluorosilane-modified silicone resin solution containing various additives under a high-speed shearing machine (rotation speed: 2000rpm), and apply ultrasonic treatment (ultrasonic power: 80W, ultrasonic frequency: 30kH) 30 minutes to get long-lasting dust-proof, anti-bacterial and anti-virus coatings.

[0036] Step 4: Coat the coating on the surface of 5G electronic product heat dissipation equipment by spraying and showering. In a normal temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com