Glutaraldehyde disinfectant as well as preparation method and application thereof

A technology of glutaraldehyde and disinfectant, which is applied in the field of glutaraldehyde disinfectant and its preparation, can solve problems such as difficulty in ensuring high stability and high biological activity, long sterilization time, poor stability of glutaraldehyde, etc., and achieve enhanced disinfection and sterilization effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

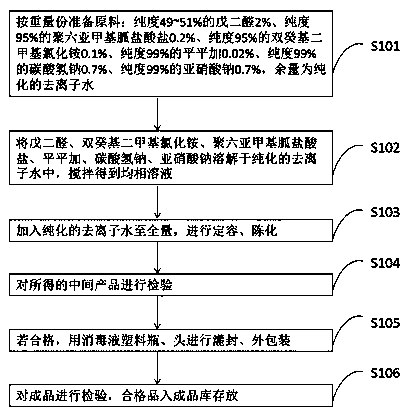

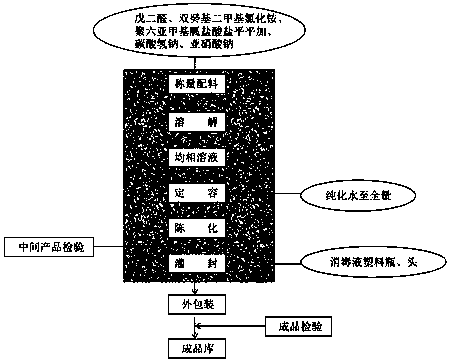

[0031] Such as figure 1 As shown, the preparation method of the glutaraldehyde disinfectant provided by the embodiment of the present invention includes the following steps:

[0032] S101: Prepare raw materials in parts by weight: 2% glutaraldehyde with a purity of 49 to 51%, didecyl dimethyl ammonium chloride with a purity of 95%, polyhexamethylene guanidine hydrochloride with a purity of 95%, and a purity of 99 Add 0-25% 0.02%, 99% pure sodium bicarbonate 0.7%, 99% pure sodium nitrite 0.7%, and the balance is purified deionized water;

[0033] S102: Dissolve glutaraldehyde, didecyldimethylammonium chloride, polyhexamethyleneguanidine hydrochloride, Ping Ping 0-25, sodium bicarbonate, and sodium nitrite in purified deionized water, and stir to obtain Homogeneous solution

[0034] S103: Add purified ionized water to full volume, and perform constant volume and aging;

[0035] S104: Inspect the obtained intermediate products;

[0036] S105: If qualified, use disinfectant plastic bottle...

Embodiment

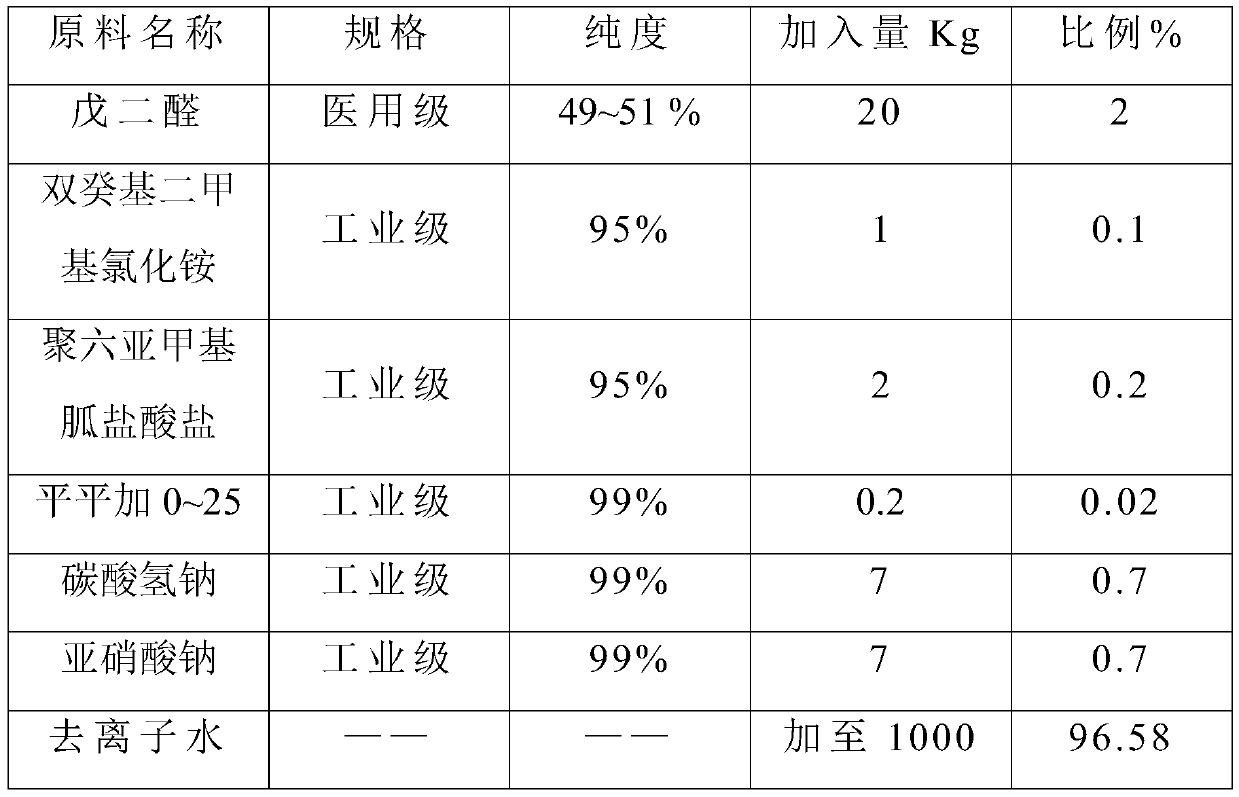

[0041] Composition of 1000kg product prescription:

[0042]

[0043] Store the prepared disinfectant at 25°C and 37°C, and measure the glutaraldehyde content regularly. The content of glutaraldehyde is determined in accordance with the method described in "Technical Specifications for Disinfection" (2002 edition).

[0044] Store at 37°C for 90 days (validity period of 2 years test), test the glutaraldehyde content of the sample, the test results are shown in the following table:

[0045]

[0046] From the data in the table, it can be seen that the product of the present invention has good stability. When the accelerated test is stored at 37°C for 90 days, the decrease rate is only 0.04%, indicating that there is almost no loss of glutaraldehyde under this condition. The product of the invention has a validity period of at least 2 years, which is comparable to the validity period of the currently marketed glutaraldehyde disinfectant. The disinfectant of the invention has a significan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com