Tungsten titanium powder mixing method

A tungsten-titanium and powder-mixing technology, which is applied in transportation and packaging, vacuum evaporation coating, coating, etc., can solve the problem that the product cannot be shipped and used normally, the cause of mottling is not found, and mottling or spots are easy to appear, etc. problems, achieve high industrial application value, ensure powder mixing efficiency, and reduce mottling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

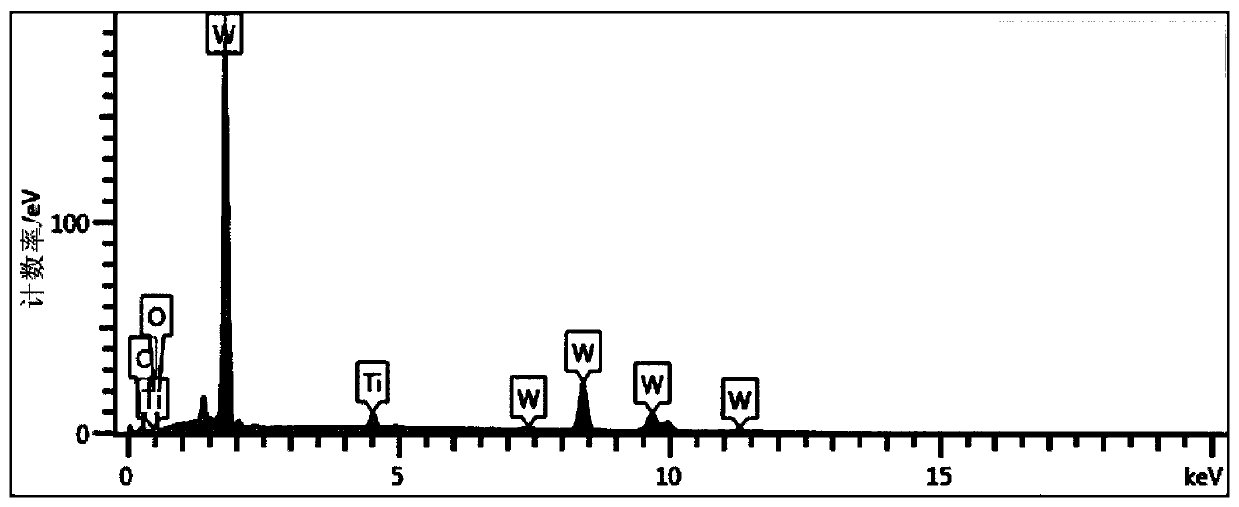

[0060] This embodiment provides a W-3% Ti tungsten-titanium powder mixing method, the method comprising the following steps:

[0061] (1) Add 17kg of the first batch of tungsten powder and 3kg of titanium powder into the V-type powder mixing machine. The mass percentage of titanium powder in the tungsten-titanium mixed powder is 15wt%. The powder time is 20h, and the speed is 8r / min;

[0062] (2) Add 10kg of the second batch of tungsten powder to the V-type powder mixing machine, so that the mass percentage of titanium powder is 10wt%, and carry out the second powder mixing. The powder mixing time is 18h, and the rotating speed is 8r / min;

[0063] (3) Add the third batch of 20kg tungsten powder to the V-type powder mixing machine, the mass percentage of titanium powder in the tungsten-titanium mixed powder is 6wt%, carry out the third powder mixing, the mixing time is 15h, and the rotating speed is 8r / min;

[0064] (4) Add 50kg of the fourth batch of tungsten powder to the ...

Embodiment 2

[0067] This embodiment provides a W-1% Ti tungsten-titanium powder mixing method, the method includes the following steps:

[0068] (1) Add 7.3kg of the first batch of tungsten powder and 1kg of titanium powder into the V-type powder mixing machine. The mass percentage of titanium powder in the tungsten-titanium mixed powder is 12wt%, and argon gas is introduced to carry out the first powder mixing. The powder mixing time is 12h, and the speed is 10r / min;

[0069] (2) Add 4.2kg of the second batch of tungsten powder to the V-type powder mixing machine, so that the mass percentage of titanium powder is 8wt%, and carry out the second powder mixing. The powder mixing time is 24h, and the rotating speed is 6r / min;

[0070] (3) Add 7.5kg of the third batch of tungsten powder to the V-type powder mixing machine. The mass percentage of titanium powder in the tungsten-titanium mixed powder is 5wt%, and the third powder mixing is performed. The powder mixing time is 24h and the rotatin...

Embodiment 3

[0074] This embodiment provides a W-10%Ti tungsten-titanium powder mixing method, the method comprising the following steps:

[0075] (1) Add 40kg of the first batch of tungsten powder and 10kg of titanium powder into the V-type powder mixing machine. The mass percentage of titanium powder in the tungsten-titanium mixed powder is 20wt%. The powder time is 24h, and the speed is 8r / min;

[0076] (2) Add 16.7kg of the second batch of tungsten powder to the V-type powder mixing machine, so that the mass percentage of titanium powder is 15wt%, and carry out the second powder mixing. The powder mixing time is 12h, and the rotating speed is 10r / min;

[0077] (3) Add 16.6kg of the third batch of tungsten powder to the V-type powder mixing machine. The mass percentage of titanium powder in the tungsten-titanium mixed powder is 12wt%, and the third powder mixing is carried out. The powder mixing time is 12h and the rotating speed is 10r / min, to obtain a homogeneously mixed tungsten-ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com