Motor embedded type headstock

A bedside box and motor-type technology, which is applied in the field of machine tools, can solve problems such as extreme reduction of machine tool transmission, poor product finish, and burnout of the electric spindle motor, so as to avoid burnout of the electric spindle motor, improve stability and transmission accuracy, and improve The effect of transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific embodiment:

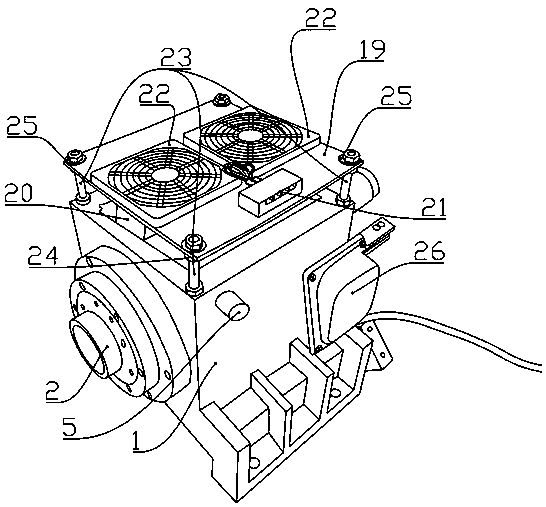

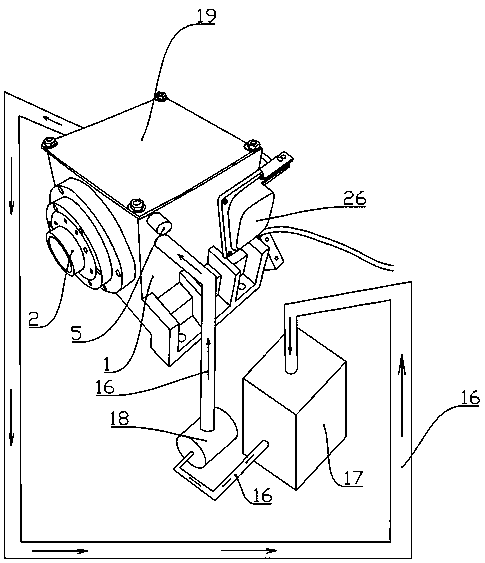

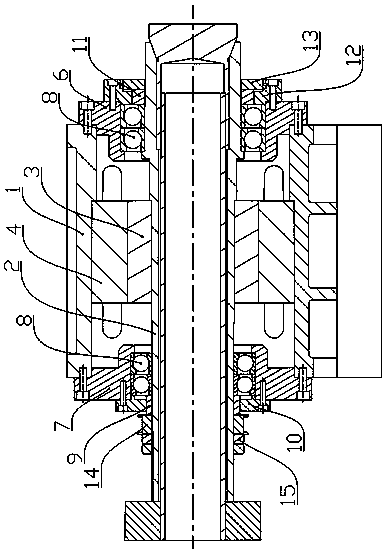

[0026] This embodiment: refer to Figure 1-3 , a built-in motor type bedside box, comprising a bedside box body 1 with a placement hole and a main shaft 2 arranged in the placement hole, a motor rotor 3 is sleeved outside the main shaft 2 in the placement hole, and The motor rotor 3 is covered with a motor stator 4 with a motor coil, and the upper end of one side of the headboard box 1 is provided with a mounting hole, and the mounting hole is provided with a temperature sensor 5 for monitoring the temperature in the box. The above-mentioned technical scheme can be provided with a clamp at the front end of the main shaft 2, and an external tensioning device for tightening the clamp is provided at the rear end of the main shaft, and can be a hydraulic, pneumatic or manual clamping device, which can be used as a bedside box After the motor inside the body 1 is energized, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com