Process for improving paint film property of cork floor

A technology of cork flooring and paint film, which is applied in the field of wood product manufacturing, can solve the problems of paint film stretching and burrs, long working time, and slow drying speed, so as to prevent cracking of wooden floor, improve environmental protection performance, and facilitate early use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

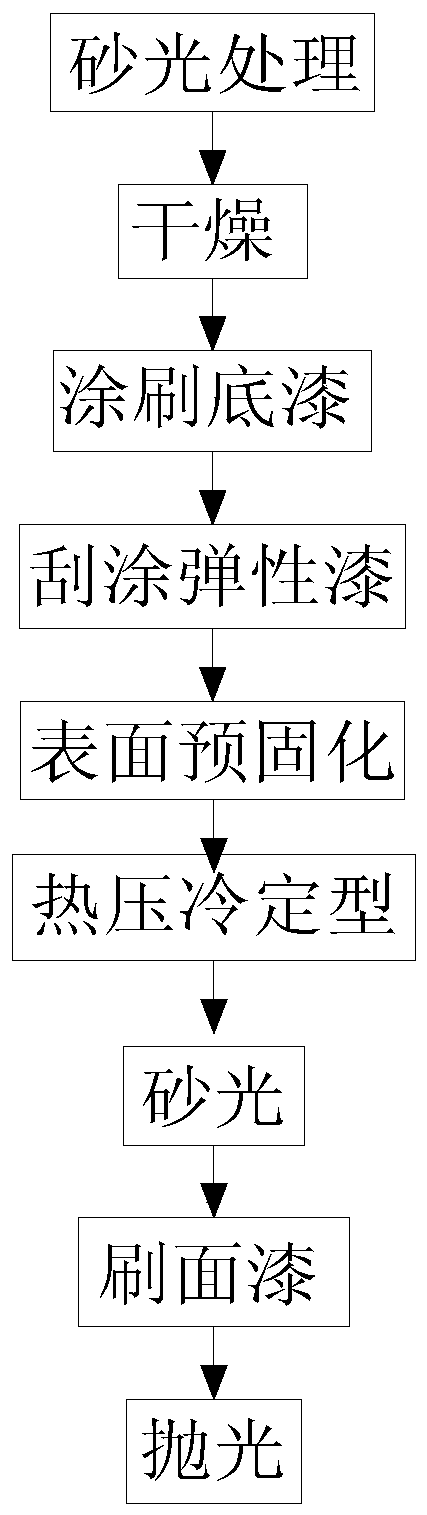

[0030] A process for improving the performance of a cork floor paint film, comprising the steps of:

[0031] Step 1: Sanding treatment: use sandpaper to sand the surface of the cork floor;

[0032] Step 2: Drying: Wipe the cork floor after sanding in step 1 with a wet rag, then put it into the drying box for drying treatment, and then put it in a constant temperature and humidity box for balance;

[0033] Step 3: Apply primer: After the cork floor in step 2 is dry, apply primer on the cork floor; Step 4: Scrape elastic paint: Manually scrape the elastic paint on the outer surface of the primer in step 2 ;

[0034] Step 5: Surface pre-curing: place the cork floor painted with elastic paint in step 4 in an oven for drying;

[0035] Step 6: Hot pressing and cold setting: hot pressing the dried cork flooring in step 5, and then pressurizing and cooling to shape after hot pressing;

[0036] Step 7: Sanding: Use water sandpaper to polish the cork floor formed by hot pressing and ...

Embodiment 2

[0048] A process for improving the performance of a cork floor paint film, comprising the steps of:

[0049] Step 1: Sanding treatment: use sandpaper to sand the surface of the cork floor;

[0050] Step 2: Drying: Wipe the cork floor after sanding in step 1 with a wet rag, then put it into the drying box for drying treatment, and then put it in a constant temperature and humidity box for balance;

[0051] Step 3: Apply primer: After the cork floor in step 2 is dry, apply primer on the cork floor; Step 4: Scrape elastic paint: Manually scrape the elastic paint on the outer surface of the primer in step 2 ;

[0052] Step 5: Surface pre-curing: place the cork floor painted with elastic paint in step 4 in an oven for drying;

[0053] Step 6: Hot pressing and cold setting: hot pressing the dried cork flooring in step 5, and then pressurizing and cooling to shape after hot pressing;

[0054] Step 7: Sanding: Use water sandpaper to polish the cork floor formed by hot pressing and co...

Embodiment 3

[0066] A process for improving the performance of a cork floor paint film, comprising the steps of:

[0067] Step 1: Sanding treatment: use sandpaper to sand the surface of the cork floor;

[0068] Step 2: Drying: Wipe the cork floor after sanding in step 1 with a wet rag, then put it into the drying box for drying treatment, and then put it in a constant temperature and humidity box for balance;

[0069] Step 3: Apply primer: After the cork floor in step 2 is dry, apply primer on the cork floor; Step 4: Scrape elastic paint: Manually scrape the elastic paint on the outer surface of the primer in step 2 ;

[0070] Step 5: Surface pre-curing: place the cork floor painted with elastic paint in step 4 in an oven for drying;

[0071] Step 6: Hot pressing and cold setting: hot pressing the dried cork flooring in step 5, and then pressurizing and cooling to shape after hot pressing;

[0072] Step 7: Sanding: Use water sandpaper to polish the cork floor formed by hot pressing and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com