Embedded self-lubricating air ring bearing and manufacturing method thereof

A self-lubricating, air-ring technology, applied in the direction of sliding contact bearings, bearings, shafts and bearings, etc., can solve the problems of insufficient combination of shaft housing and bushing, easy sliding of bushing and shaft housing, and short service life of bearings. Achieve the effect of small friction coefficient, improve mechanical strength and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Attached below Figure 1-6 Embodiments of the present invention will be further described in detail.

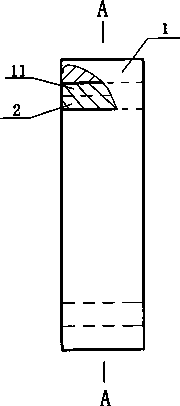

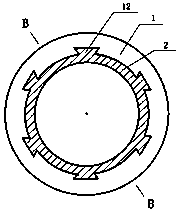

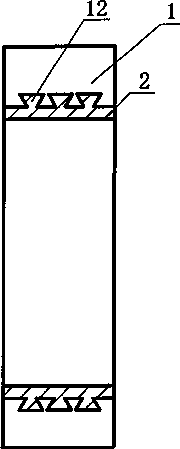

[0022] Such as figure 1 As shown, the embedded self-lubricating air ring bearing of the present invention includes a shaft housing 1, the inside of which is a hollow cylinder; and a lubricating bush 2 arranged on the inner surface of the shaft housing 1. The difference is that the shaft housing 1 The inner wall is equipped with a group of radial or axial distribution grooves 11. The above-mentioned bushing 2 is a low-friction sliding ring made of polytetrafluoroethylene (PTFE is the trade name) as the base material. 1 The shape of the inner wall matches. Such as Figure 2-3 As shown, a group of grooves 11 on the inner wall of the above-mentioned axle housing 1 are dovetail grooves 12, and the dovetail grooves 12 can make the bushing 2 and the axle housing 1 more firmly connected. Such as Figure 4-5 As shown, a group of grooves 11 on the inner wall of the above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com