Sludge feeding test device capable of conditioning ionic mobility and molecular weight

A technology of feeding test and feeding device, applied in dehydration/drying/thickened sludge treatment, fixed filter element filter, filtration separation, etc., can solve problems such as cumbersome process, increased filter cake volume, poor flocculation effect, etc. , to improve test efficiency and simplify preparation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

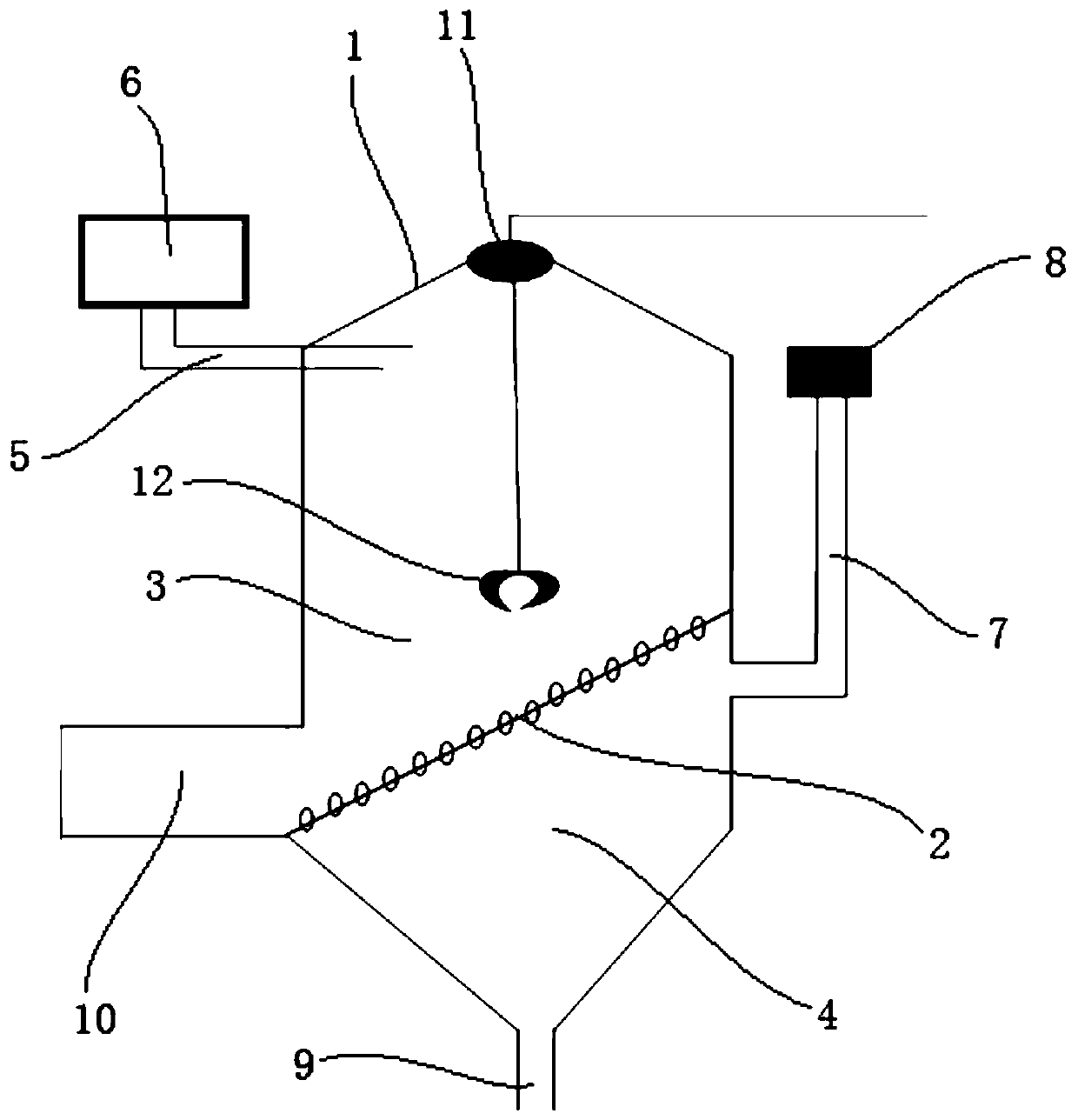

[0029] This embodiment provides a kind of sludge feed test device that can be adjusted and tempered, such as figure 1 Shown:

[0030] Including the main body 1 of the feeding device, the interior of the main body 1 of the feeding device is provided with a housing chamber, the middle part of the housing chamber is provided with a filter mechanism 2, and the filter mechanism 2 divides the housing chamber into upper and lower parts, and the upper part is a filter chamber 3 , the lower part is the conditioning chamber 4, the upper end of the feed device main body 1 is provided with a feed pipe 5, and the feed pipe 5 is provided with a feed port 6 at one end outside the feed device main body 1, and the other end communicates with the filter chamber 3 Inside, the bottom of the conditioning chamber 4 is designed in a funnel shape, and the bottom end is provided with a discharge port 9, and a dosing pipeline 7 is also provided on the side wall of the main body 1 of the feeding device,...

Embodiment 2

[0033] As an optimization of the above-mentioned embodiment, the filter mechanism 2 is a filter baffle, and several filter through holes are arranged in the filter baffle. The diameter of the filter through hole is less than or equal to 0.25mm. When it is applied, it can effectively screen out the required solid particles, filter out larger sand and stones, and improve the efficiency of the subsequent plate and frame filter press test.

Embodiment 3

[0035] As an optimization of the above embodiment, the filter baffle is arranged obliquely in the accommodating cavity, so that the upper surface of the filter baffle forms a slope surface. A sand recovery chamber 10 is provided on the side wall of the filter chamber 3 at the bottom of the slope surface of the filter baffle. The mouth of the feed pipe 5 communicating with the filter chamber 3 is located directly above the slope top of the filter baffle. When it is used, the sludge injected by the feed pipe 5 directly falls on the top of the slope of the filter baffle, and then slides down the slope, wherein the required solid particles fall into the conditioning chamber 4 through the filter holes, and the larger sand and stone roll Reclaim in the gravel recovery chamber 10 that falls to the top and bottom of the slope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com