Organic semiconductor device without electron transport layer and preparation method of organic semiconductor device

An organic semiconductor, electron transport layer technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the adverse effects of transport layer material stability and device performance, complicate device manufacturing process, and device stability. Disadvantages and other problems, to achieve the effect of prolonging life, improving yield, and increasing open circuit voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

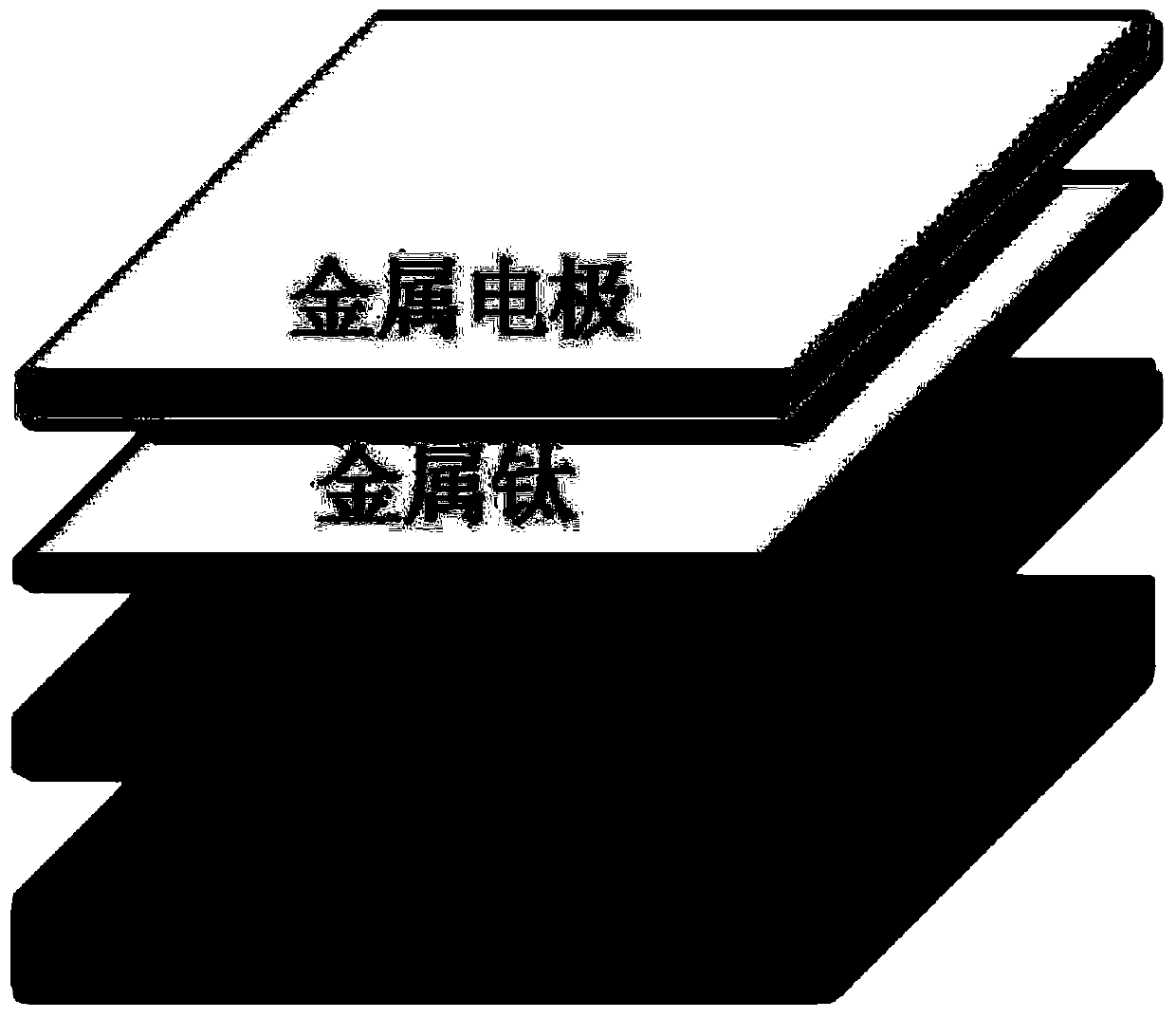

[0030] A method for preparing an organic semiconductor device without an electron transport layer as described above, comprising the following steps:

[0031] S1: Preparation of thin films of organic materials

[0032] Taking transparent ITO glass as a substrate, uniformly prepare a layer of organic material thin film on its surface to obtain a substrate covered with organic material thin film;

[0033] S2: Preparation of metallic Ti film

[0034] Taking the substrate covered with an organic material thin film prepared in step S1, depositing a metal Ti thin film on the surface of the organic material thin film by thermal evaporation, magnetron sputtering or electroplating to obtain a substrate covered with a metal Ti thin film and an organic material thin film, said The thickness of the metal Ti film is not more than 30nm;

[0035] S3: Preparation of metal electrode film

[0036] Take the substrate covered with the metal Ti film and the organic material film obtained in the...

Embodiment 1

[0038] A method for preparing an organic semiconductor device without an electron transport layer, comprising the following steps:

[0039] S1: Preparation of thin films of organic materials

[0040] Get transparent ITO glass as substrate material, uniformly prepare one deck hole transport layer and organic light-emitting layer thin film on its surface, obtain the substrate that covers organic material thin film;

[0041] S2: Preparation of metallic Ti film

[0042] Get the substrate prepared in step S1, and deposit a 2nm thick metal Ti film on the surface of the organic material film by thermal evaporation to obtain a substrate covered with a metal Ti film and an organic material film;

[0043] S3: Preparation of metal electrode film

[0044] Get the substrate covered with the metal Ti film and the organic material film obtained in the above step S2, and deposit a metal Au electrode film with a thickness of 80nm on the surface of the metal Ti film by magnetron sputtering te...

Embodiment 2

[0046] A method for preparing an organic semiconductor device without an electron transport layer, comprising the following steps:

[0047] S1: Preparation of thin films of organic materials

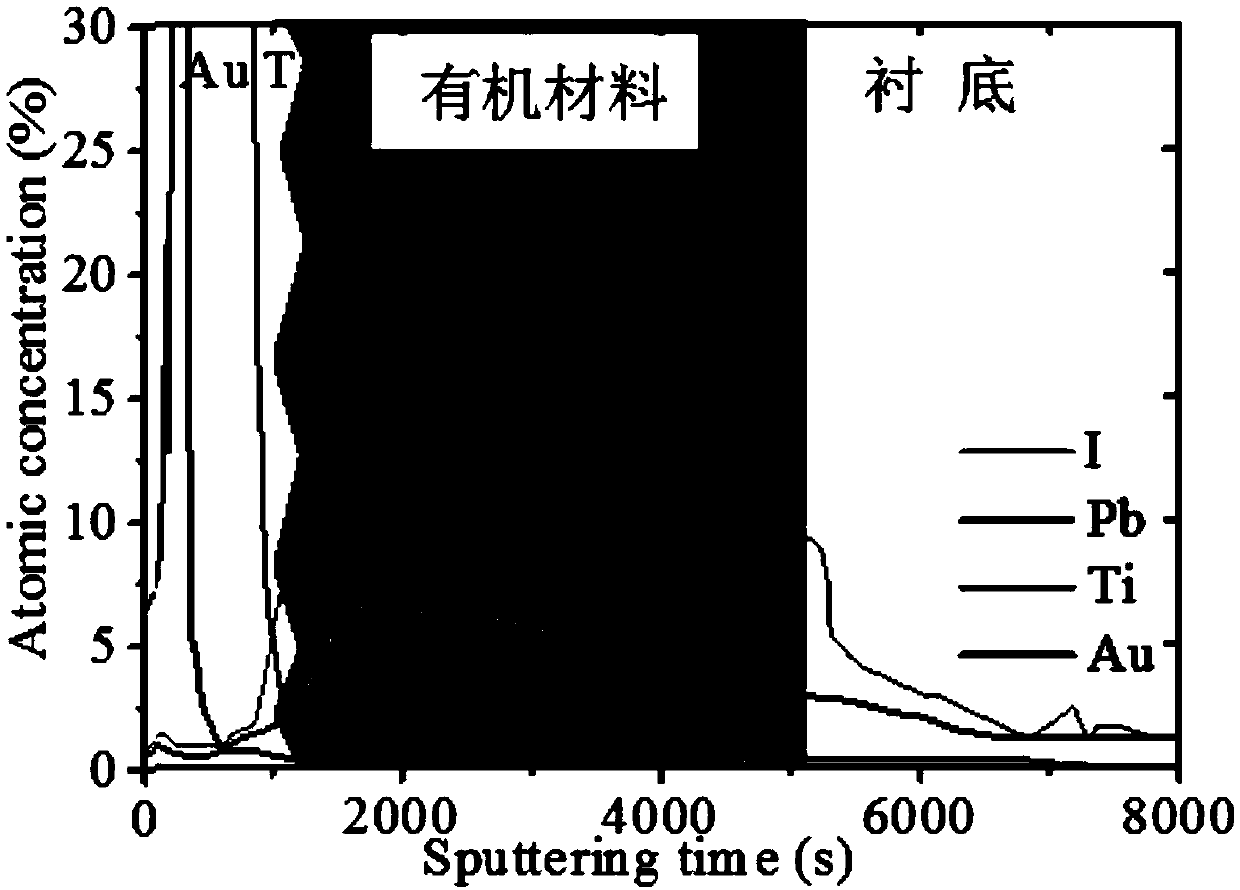

[0048] Take transparent ITO glass as the substrate material, uniformly prepare a layer of PTAA organic conductive layer and methylamine lead iodine photosensitive layer film on its surface, and obtain the substrate covered with organic-inorganic hybrid material film;

[0049] S2: Preparation of metallic Ti film

[0050] Get the substrate prepared in step S1, and deposit a 15nm thick metal Ti film on the surface of the organic-inorganic material film by electroplating to obtain a substrate covered with a metal Ti film and an organic-inorganic hybrid material film;

[0051] S3: Preparation of metal electrode film

[0052] Get the substrate that above-mentioned step S2 makes, by thermal evaporation technology, deposit the metal Ag electrode film that thickness is 100nm on the surface of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com