Preparation and construction methods of assembled foam concrete slab enclosure wall

A technology of foam concrete and construction methods, applied to walls, ceramic products, building components, etc., can solve problems such as low strength, water absorption, and easy cracking, and achieve the effects of enhancing integrity, reducing resource consumption, and improving use functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

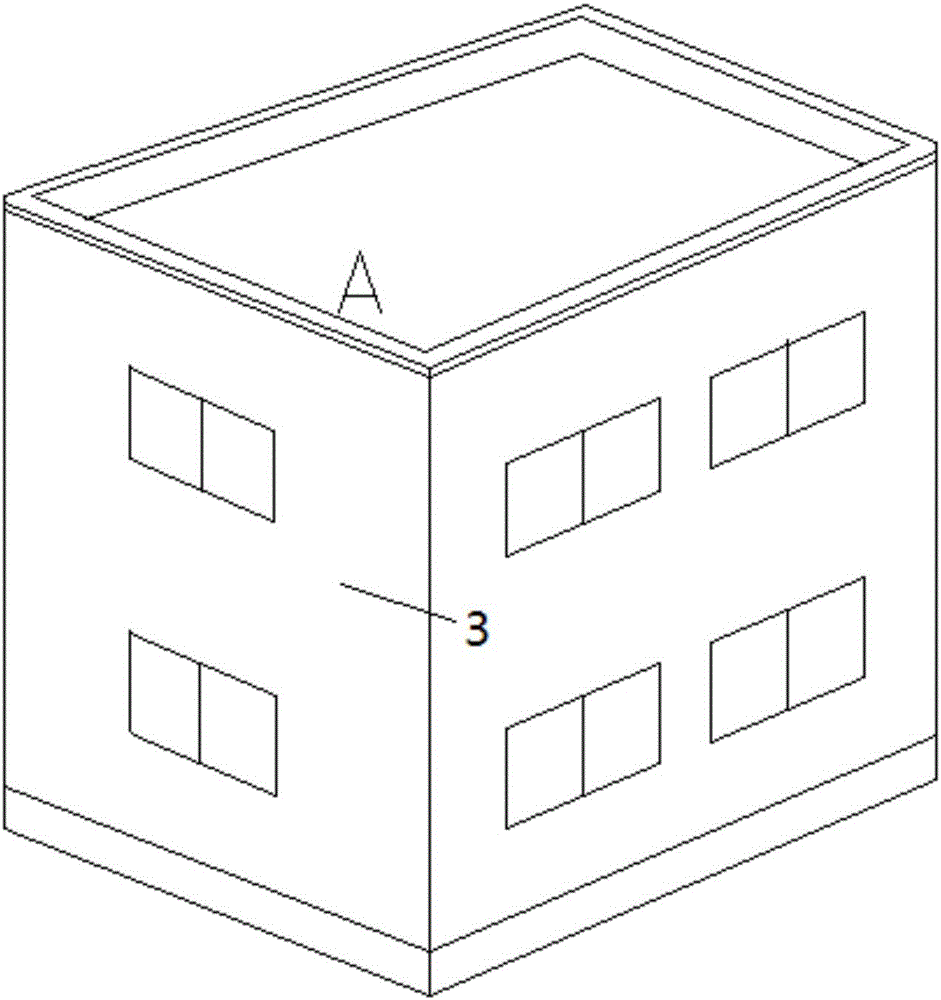

[0032] see Figure 1-4 , a method for preparing a prefabricated foam concrete slab enclosure wall, comprising the following steps:

[0033] 1) Preparation of foam: Use air pump to add air, add proportionally weighed water and foaming agent into the foam machine, pressurize it to 0.5-1.5Mpa by the air pump, and then prepare fine, uniform, good viscosity and stable foam by the foam machine the foam;

[0034] As preferably, the step 1) is pressurized to 0.8Mpa by an air pump;

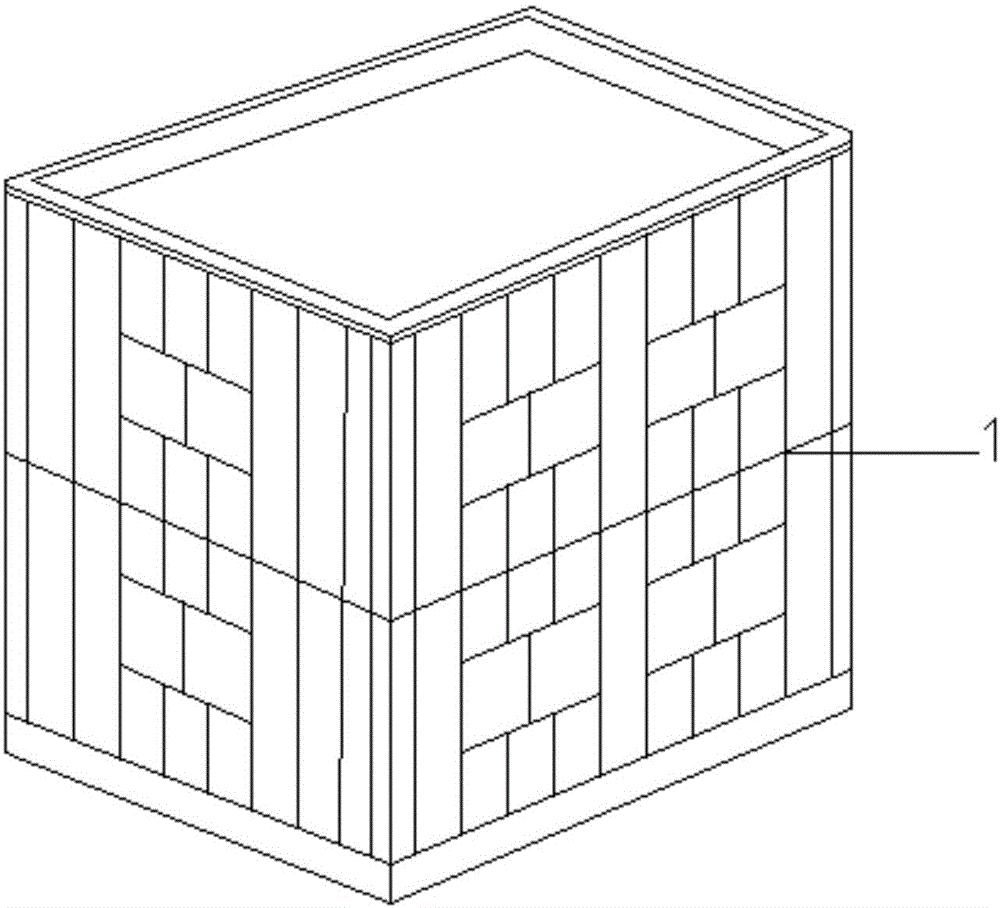

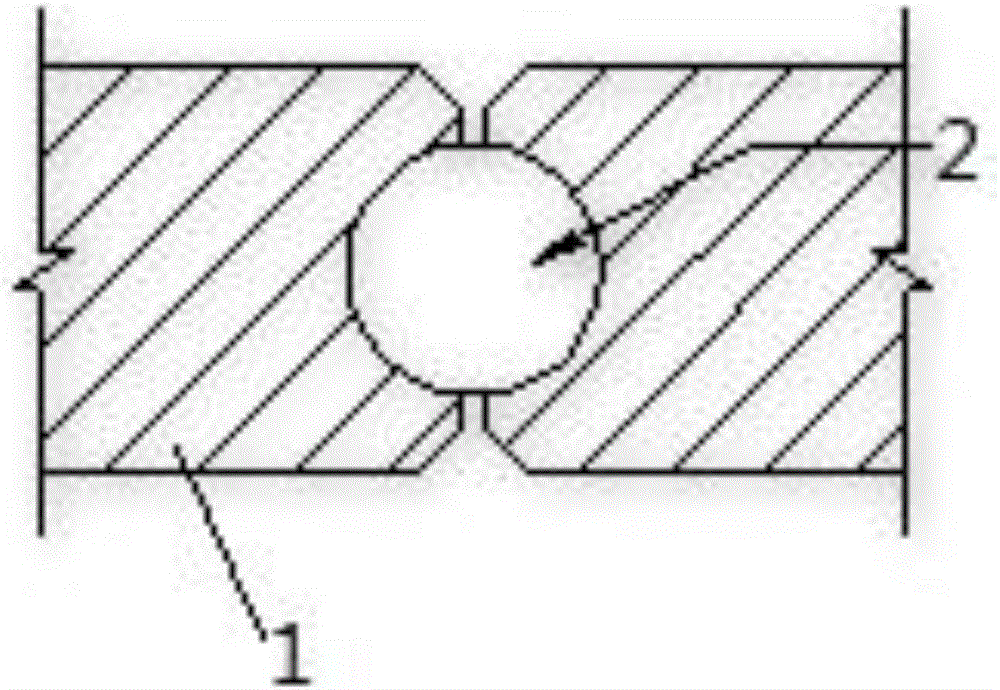

[0035] 2) Prefabricated foam concrete forming plate 1: put various raw materials into the machine and stir, then add the above foam, carry out evenly cast-in-place construction or mold molding of the built-in steel bars, smooth it after standing for 25 minutes, and put it in after standing for one day From the standard curing room to the test age, the foamed concrete forming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com