High-strength modified synthetic fiber reinforced reactive powder concrete

A technology of synthetic fiber and active powder, applied in the field of materials, can solve the problems of low reinforcement effect, easy rust and corrosion, difficult fiber dispersion, etc., and achieve the effect of improving reinforcement effect and reinforcement efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The preferred embodiments of the present invention will be described in detail below.

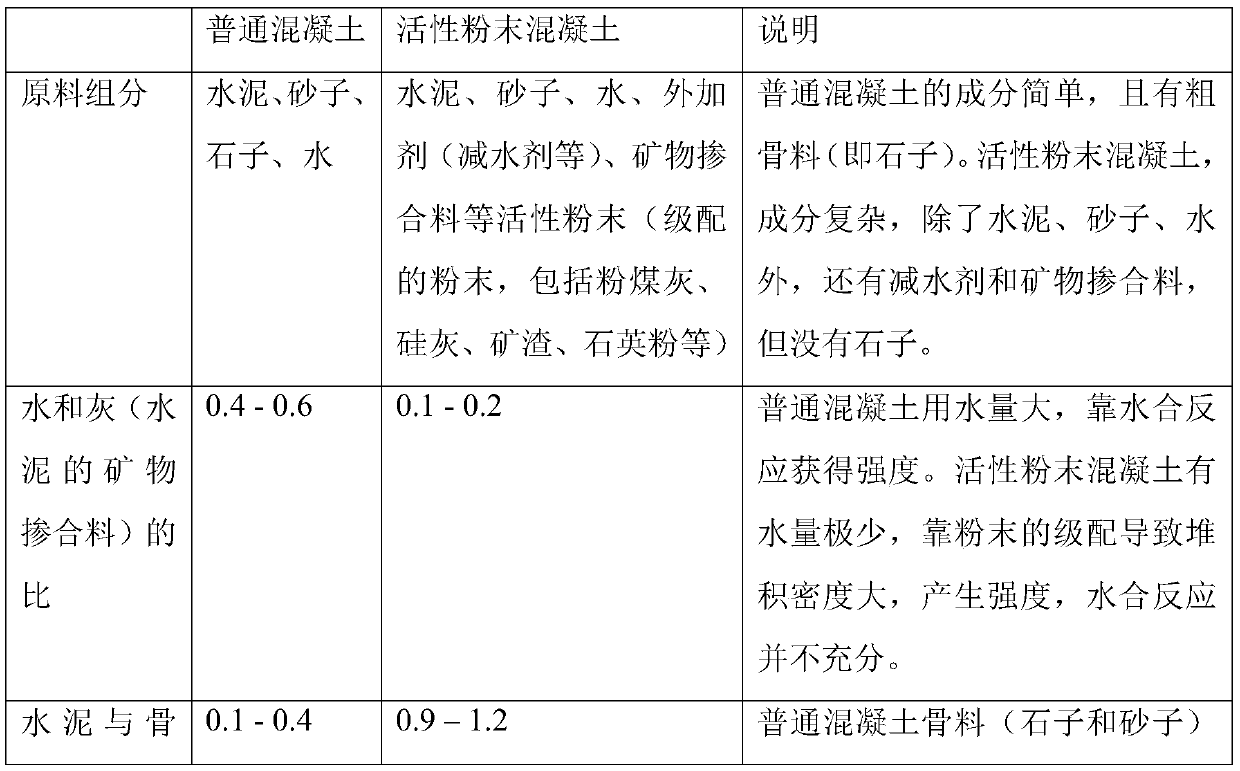

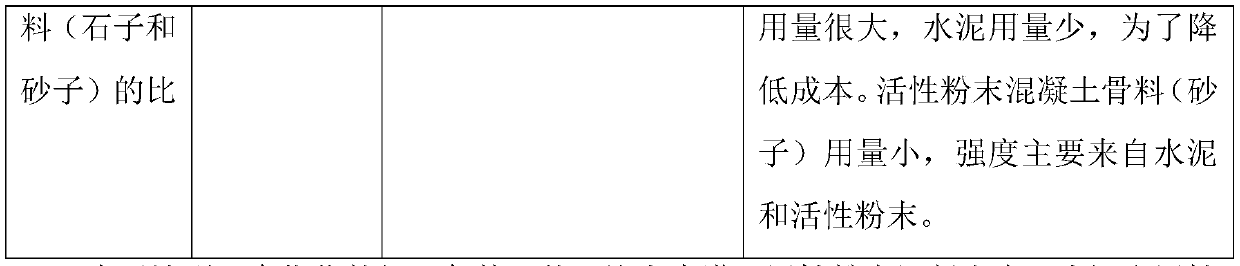

[0032] A high-strength modified synthetic fiber-reinforced reactive powder concrete. The modifier and synthetic resin are mixed as listed in Table 1, and then melted or melt-spinned. Part of the group undergoes secondary surface modification. The high-strength modified synthetic fiber is prepared; then the high-strength modified synthetic fiber is added to the reactive powder concrete and fully stirred until uniform; finally the concrete is poured and cured for 28 days.

[0033] Table 1 shows the specimen information of high-strength modified synthetic fiber reinforced reactive powder concrete. Control 1 is concrete without fiber, control 2 is concrete with low-strength unmodified synthetic fiber, and control 3 is steel with steel. Fiber concrete. The control group 4 and the control group 5 are the fiber dosage lower and higher than the protection range group. Specimen 1-6 are specimens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com