Microstructure surface antifouling material and preparation method thereof

A microstructure, antifouling technology, applied in antifouling/underwater coatings, special surfaces, devices for coating liquids on surfaces, etc., can solve problems such as difficulties in large-scale engineering applications, achieve good potential economic benefits, The effect of preventing the adhesion of marine organisms and meeting the needs of long-term antifouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

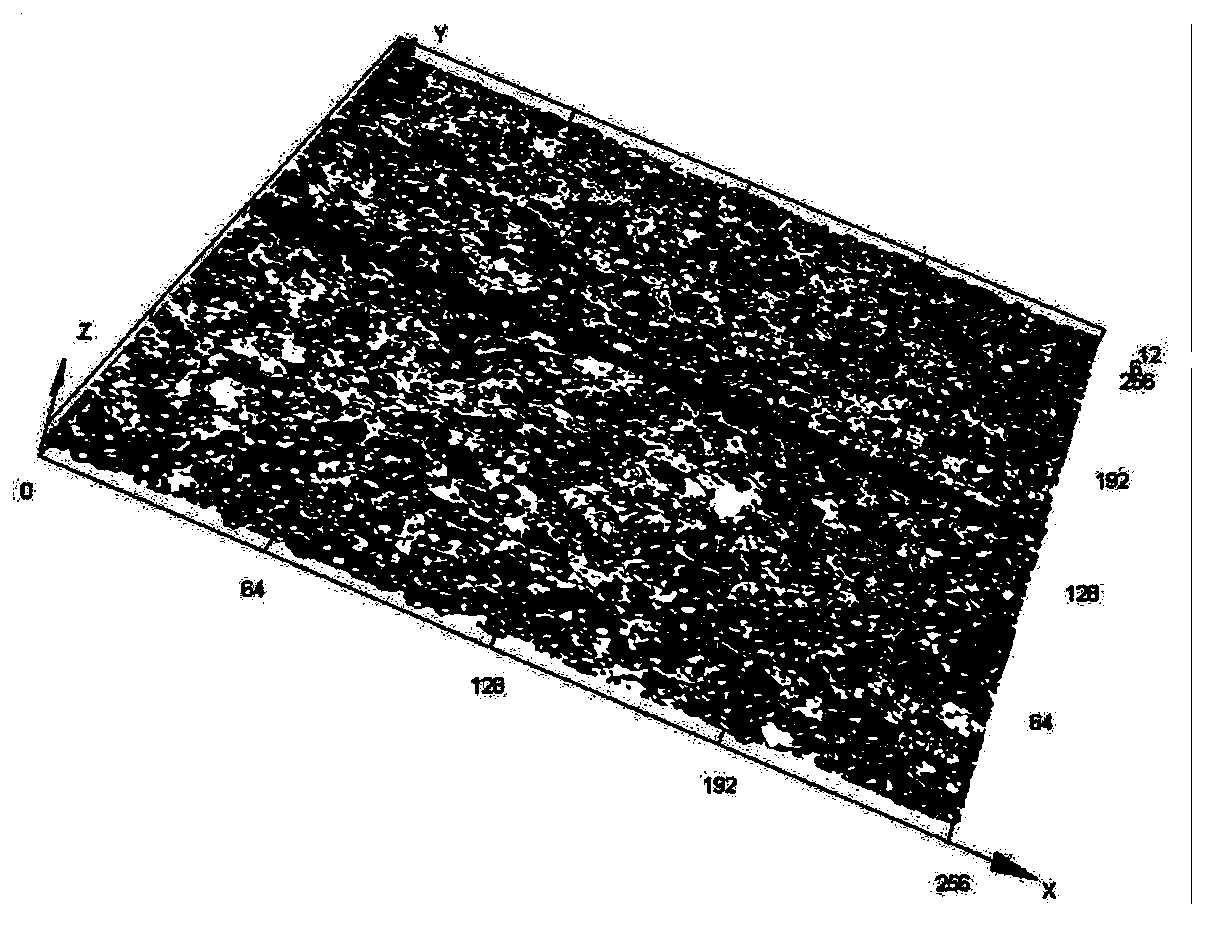

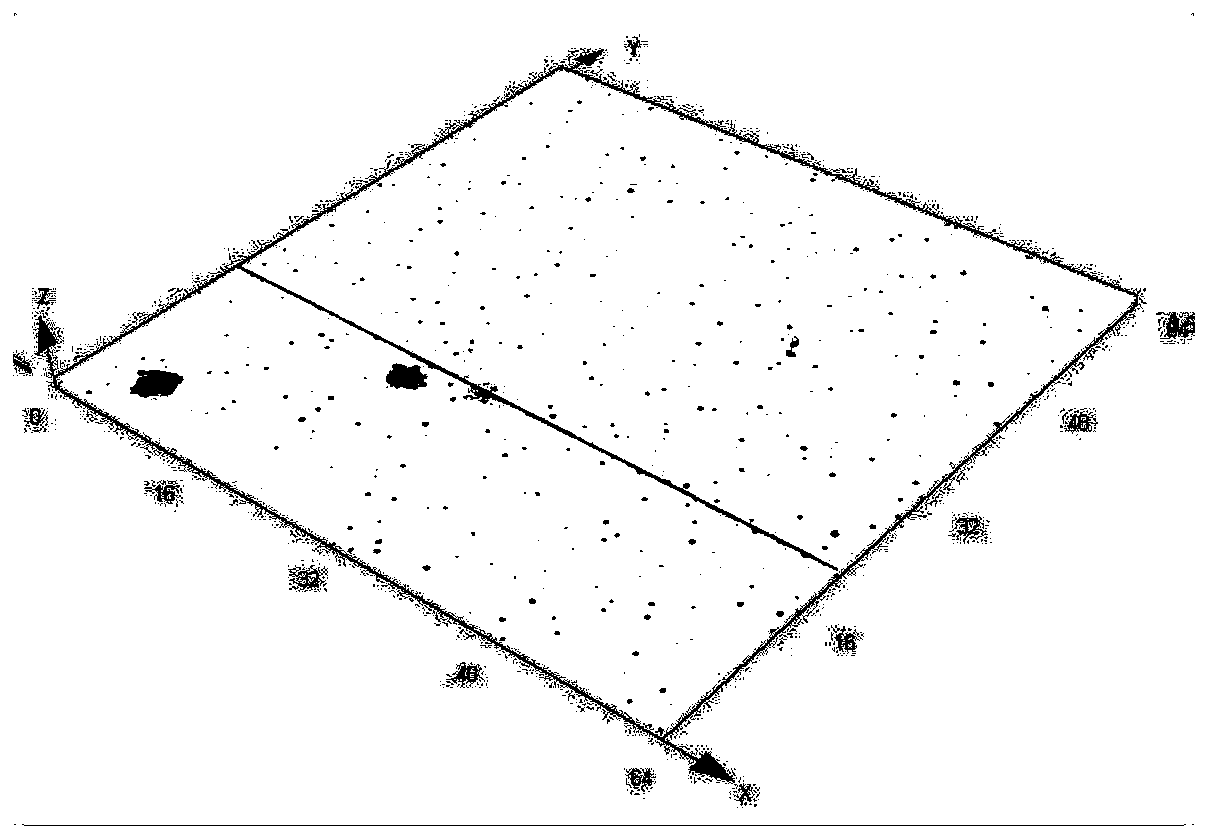

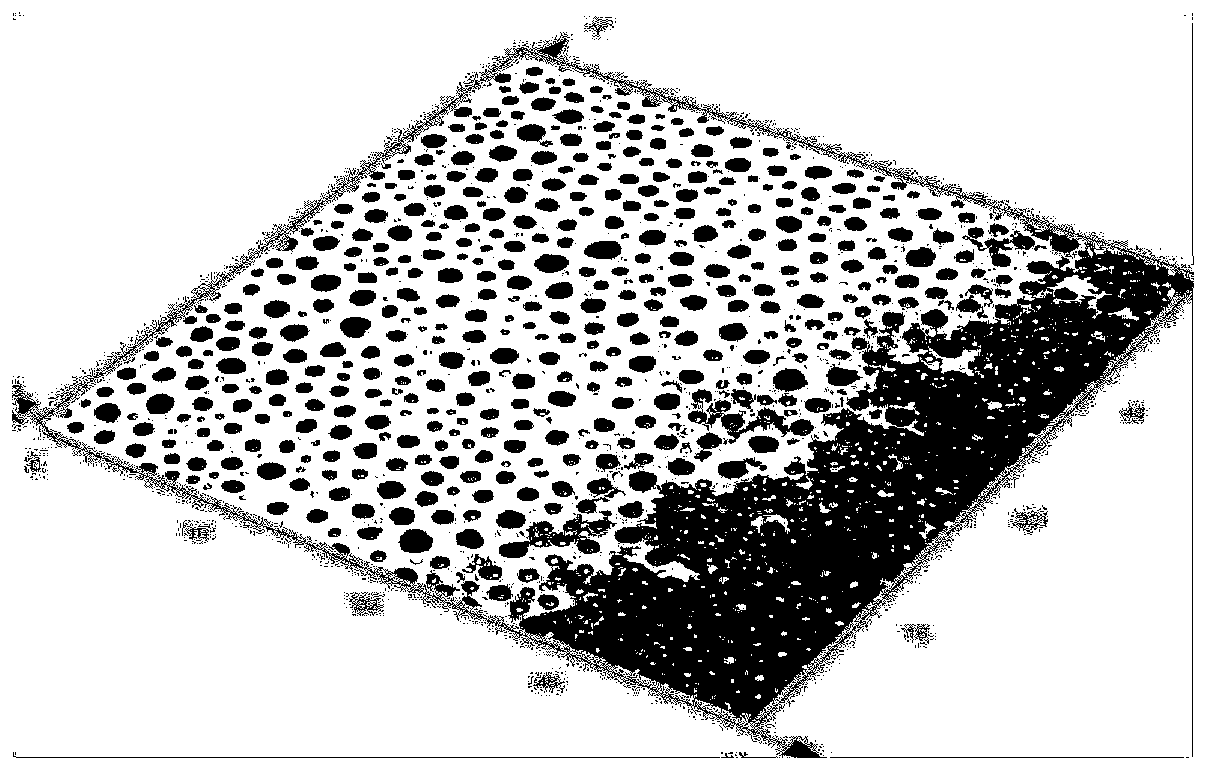

Embodiment 1

[0016] The specific process of the preparation method of the microstructure surface antifouling material involved in this embodiment is as follows: sequentially add 75 parts by mass of hydroxyl-terminated polydimethylsiloxane and 10 parts by mass of acrylonitrile with a mass percentage of 10% to a stirred tank. Nitrile grafted silicone resin and 10 parts by mass of dibutyltin dilaurate and silicon 40 are mixed to form a compound. After stirring evenly, add 3 parts by mass of ethylenediamine to form a mixture, add 1 part by mass of xylene, stir evenly, pass After degassing and removing bubbles under reduced pressure, it is coated on the surface of the substrate to form a coating. After the coating is cured, the water-soluble organic amine is washed and dissolved to remove water and absorb water to form micro droplets to prepare a micron-scale microstructure surface antifouling material.

[0017] The anti-fouling biological adhesion test process of the micro-structured surface anti-...

Embodiment 2

[0019] The specific process of the preparation method of the microstructure surface antifouling material involved in this embodiment is: sequentially adding 45 parts by mass of hydroxyl-terminated polydimethylsiloxane and 45 parts by mass of acrylonitrile with 1% acrylonitrile by mass into the stirred tank. Nitrile grafted silicone resin and 6 parts by mass of stannous octoate and methyltriethoxysilane are mixed to form a compound. After stirring evenly, add 1 part by mass of triethylenediamine to form a mixture, add 10 parts by mass of xylene, Stir uniformly, remove bubbles by degassing under reduced pressure, and apply to the surface of the substrate to form a coating. After the coating is cured, the water-soluble organic amine is washed and dissolved to remove water-soluble organic amines and absorb water to form micro-droplets to prepare micron-scale microstructure surface antifouling material.

Embodiment 3

[0021] The specific process of the preparation method of the microstructure surface antifouling material involved in this embodiment is: sequentially adding 60 parts by mass of hydroxyl-terminated polydimethylsiloxane and 30 parts by mass of acrylonitrile with a mass percentage of 2% to a stirred tank. Nitrile grafted silicone resin and 8 mass parts of dibutyl diacetyl tin and silicon 40 are mixed to form a compound. After stirring evenly, add 2 mass parts of diethylene triamine to form a mixture, add 5 mass parts of xylene, and stir Uniformity, after the bubbles are eliminated by degassing, the coating is applied to the surface of the substrate to form a coating. After the coating is cured, the water-soluble organic amine is washed and dissolved to remove water-soluble organic amines and form micro-droplets to prepare micron-scale micro-structured surface antifouling materials .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com