Composite gun body, stainless steel smelting system and steel ladle top blowing reduction and desulfurization process

A gun body and ladle technology, applied in the field of stainless steel smelting, can solve the problems of reducing desulfurization effect and increasing slag viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

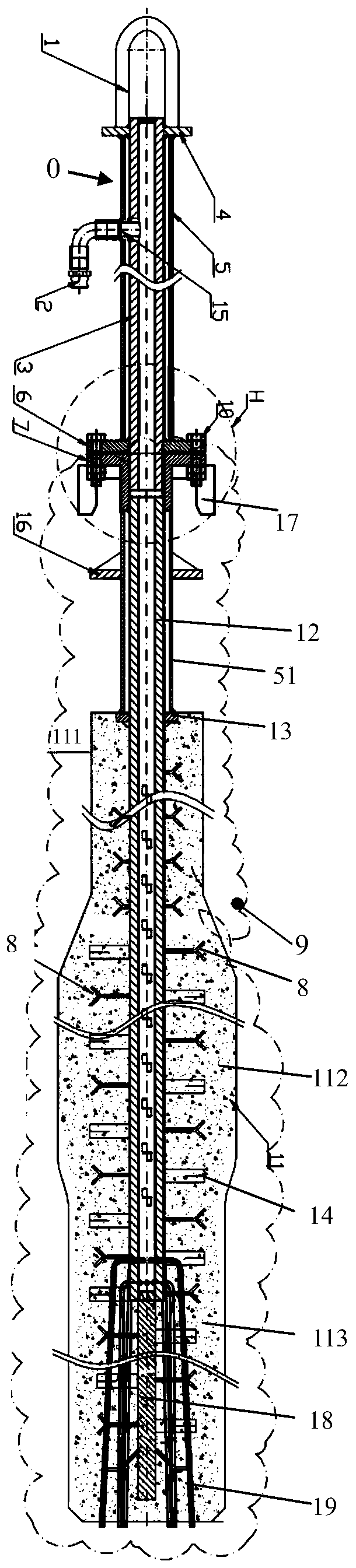

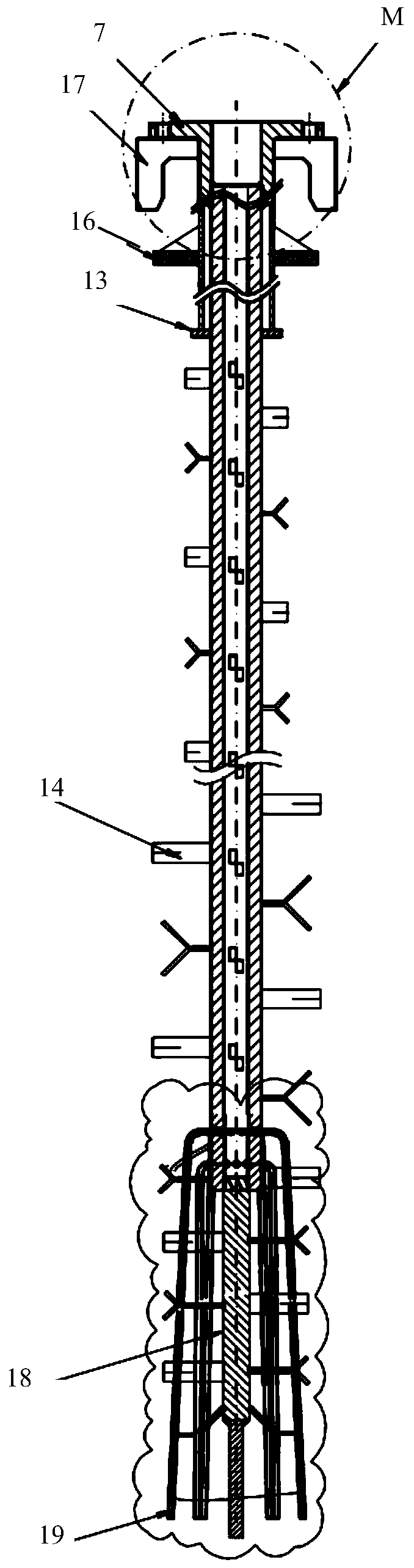

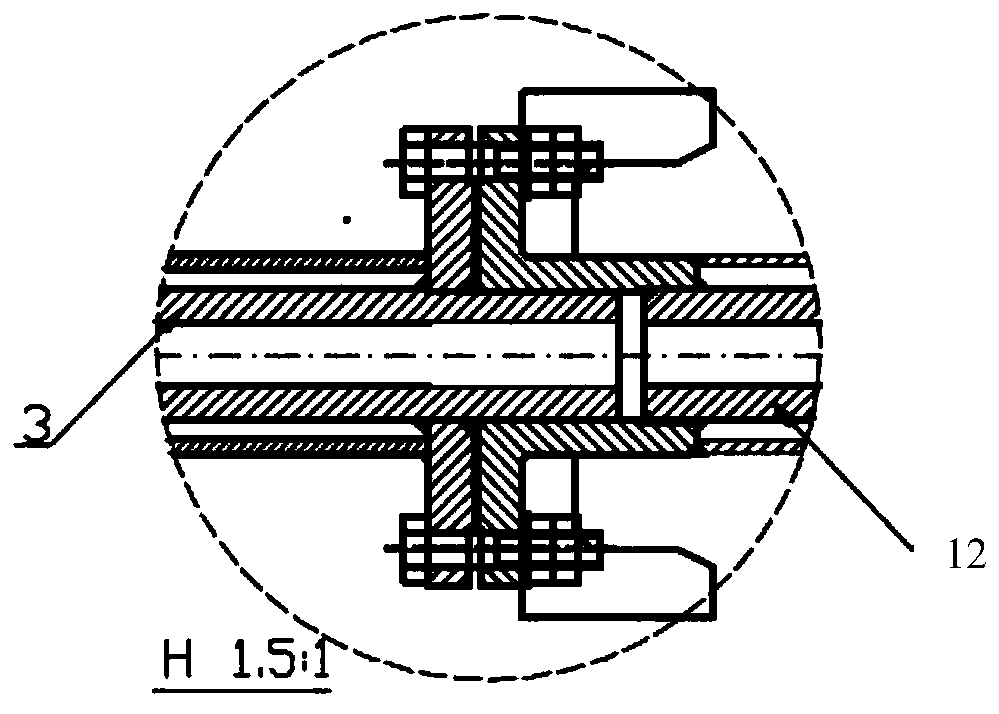

[0125] This embodiment provides a composite gun body, its structural schematic diagram is as follows Figure 1-Figure 2 as shown, figure 1 The enlarged schematic diagram of H in image 3 as shown, figure 2 The enlarged schematic diagram of M in Figure 5 shown, from Figure 1-Figure 3 and Figure 5 It can be seen from the figure that the composite gun body includes the upper part 0 of the gun body and the lower part 9 of the gun body. The first casing 5 and the upper section 6 of the sealing flange, such as Figure 8a-Figure 8b As shown; the outer wall of the first seamless steel pipe 3 is fixed with a fixed plate 4 along the circumferential direction near its closed end, the first sleeve 5 is sleeved outside the first seamless steel pipe 3, and the first seamless steel pipe 3 One end of the casing 5 is fixed under the fixing plate 4, and the other end of the first casing 5 is fixed on the upper section 6 of the sealing flange; between the first seamless steel pipe 3 an...

Embodiment 2

[0144] This embodiment provides a stainless steel smelting system, including an electric arc furnace, a ladle, an AOD furnace, and a slag removal station, the slag removal station is provided with a mobile smoke hood, wherein the stainless steel smelting system also includes the above-mentioned embodiment 1. The composite gun body of the composite gun body, the composite gun body passes through the moving fume hood and is inserted into the molten soup contained in the ladle;

[0145] In this embodiment, the system further includes a lifting device for lifting the composite gun body;

[0146] In this embodiment, the clearance of the ladle is greater than 500 mm.

Embodiment 3

[0148] This embodiment provides a stainless steel ladle top blowing stirring reduction and pre-desulfurization process, wherein the process is carried out using the stainless steel smelting system provided in Example 2, which includes:

[0149](1) Put the slag-containing soup (the amount is 9-11 tons) from the electric arc furnace into the ladle, and the temperature of the slag-containing soup from the electric arc furnace is 1550-1600°C; then insert the composite gun body In the molten soup in the ladle, nitrogen or argon gas is blown into the ladle through the composite gun body and stirred to make the molten soup vortex; then add a reducing agent to the ladle to reduce the slag in the molten soup treating to reduce chromium oxides in said slag;

[0150] (2) Carry out the slag removal operation on the ladle after the reduction treatment, after the slag removal operation, the residual slag amount is ≤500kg;

[0151] (3) Continue to blow nitrogen or argon into the ladle throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com