Construction method for mass concrete temperature crack control

A large-volume concrete and temperature cracking technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of damage, layout form not proposed, and cooling effect is not obvious, so as to reduce the temperature difference and reduce the possible sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the examples.

[0028] The following examples are used to illustrate the present invention, but cannot be used to limit the protection scope of the present invention. The conditions in the embodiment can be further adjusted according to the specific conditions, and the simple improvement of the method of the present invention under the premise of the concept of the present invention belongs to the protection scope of the present invention.

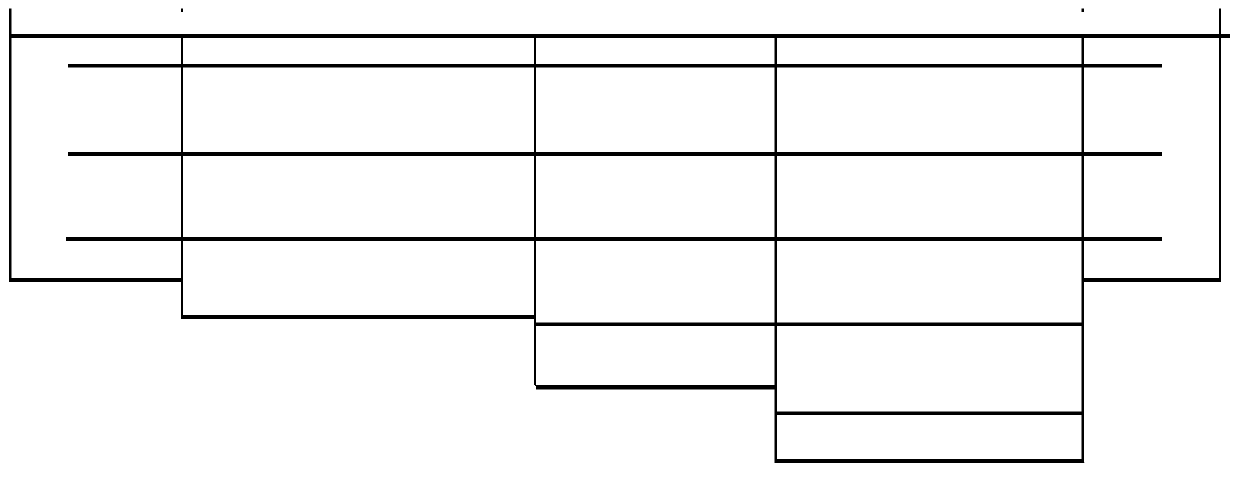

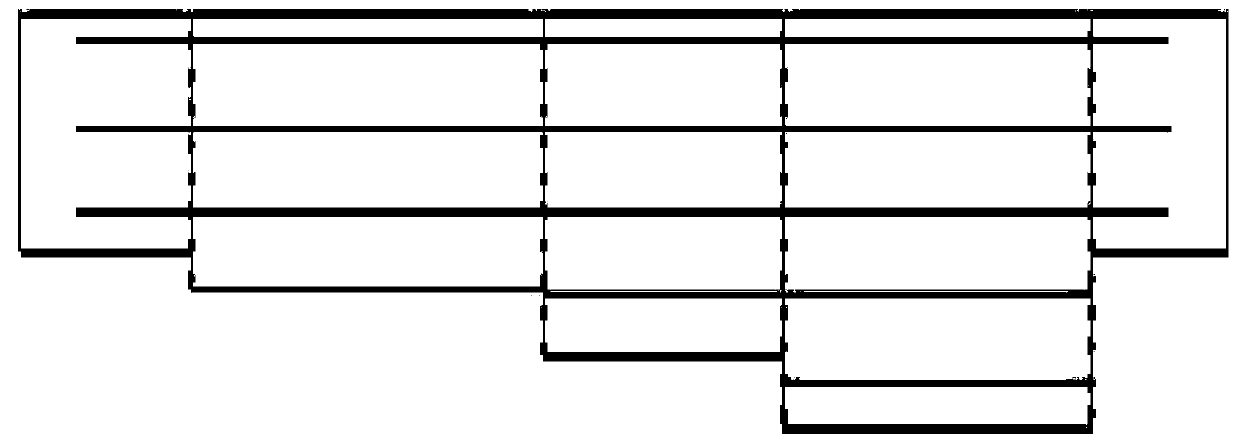

[0029] see Figure 1-4 , the invention provides a construction method for controlling temperature cracks in large-volume concrete, including aluminum-plastic pipes buried inside the concrete, temperature measuring sensors, copper joints connected by aluminum-plastic pipes, snake skin pipes on the concrete surface, and aluminum-plastic pipes for connecting Iron wire for plastic tube and snake skin tube, U-shaped buckle for fixing snake skin tube, plastic film,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com