Electron beam furnace bulk material feeding mechanism

A technology of feeding mechanism and electron beam furnace, which is applied in the direction of charge, furnace, crucible furnace, etc., can solve the problems of low precision and slow speed, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments will be described in detail below in conjunction with the accompanying drawings.

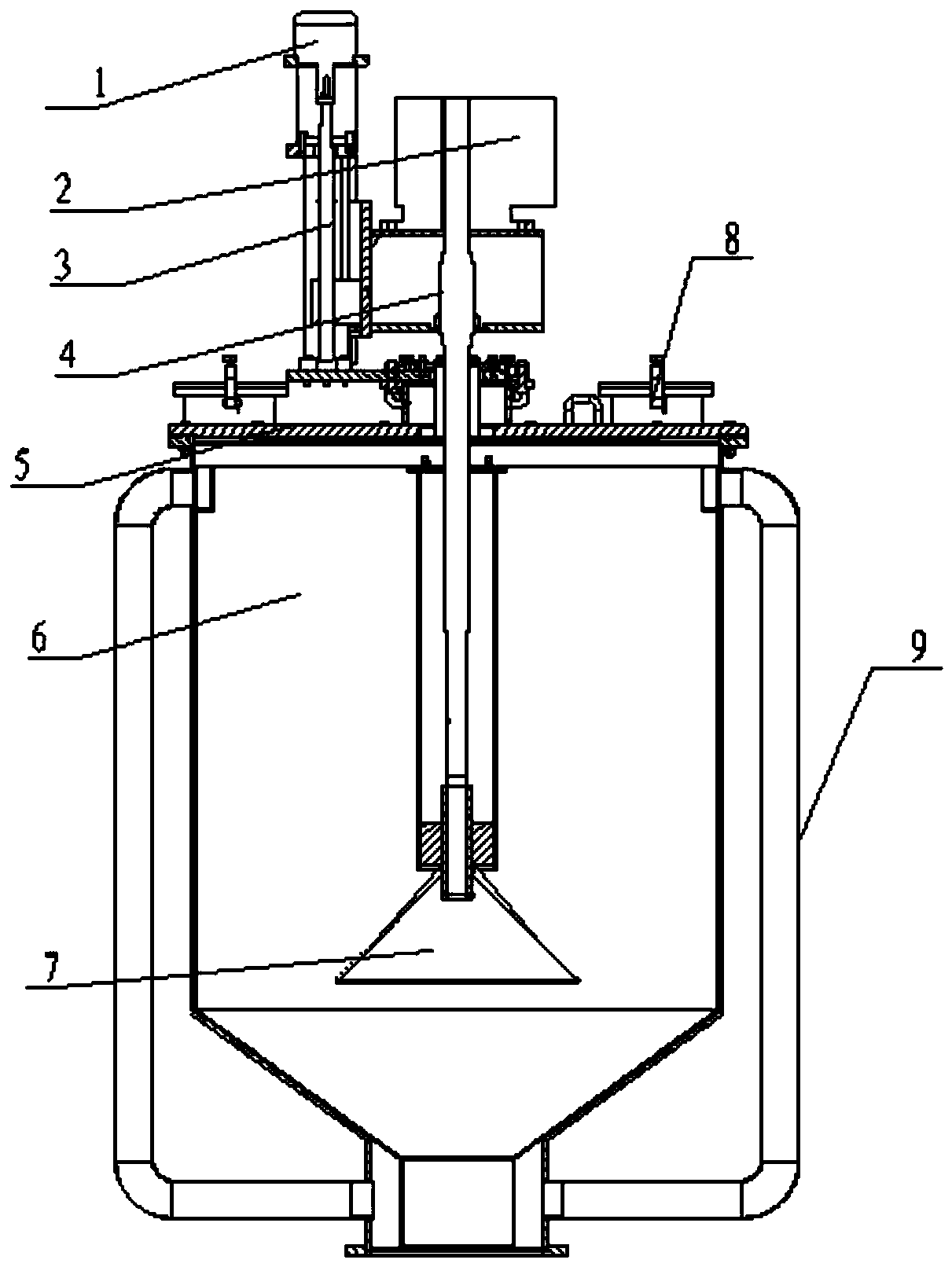

[0014] Such as figure 1 As shown, the bulk material cylinder 6 is a stainless steel welded structure, and the inner wall is lined, which can be changed according to different materials to prevent material contamination. The bulk material cover 5 flanges are symmetrically distributed to the left and right, and the material discharge ports 5 are convenient for feeding. The middle part is the rod rotation and lifting mechanism. After the material is put into the material barrel, the rotating lifting shaft 4 and the rotary blade 7 are driven by the rotating motor 2 to make the material enter the melting chamber. The lower end of the rotating lifting shaft 4 can freely float upwards. For the same batch of materials, the gap between the rotating vane 7 and the bulk material cylinder can be adjusted to ensure that the materials slide down smoothly. The floating dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com