Soft multi-core group ceramic capacitor and production method thereof

A technology of ceramic capacitors and production methods, which is applied in the manufacture of multiple fixed capacitors, capacitors, capacitors, etc., can solve the problems of long development cycle of molded packaging molds, single product shape and structure, long design and development cycle, etc., to achieve strong shock resistance and Effects of environmental adaptability, rich appearance, and shortened R&D cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

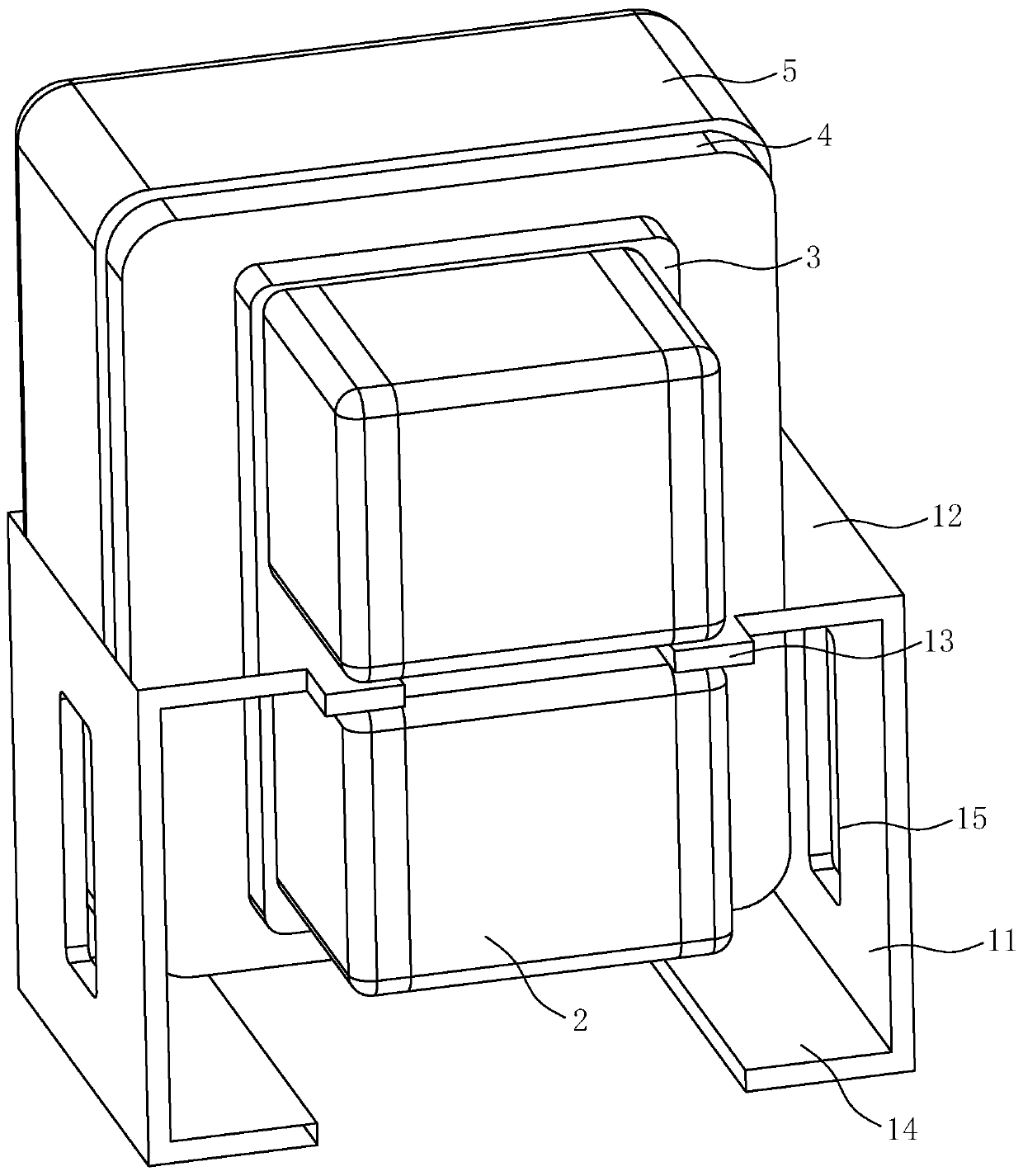

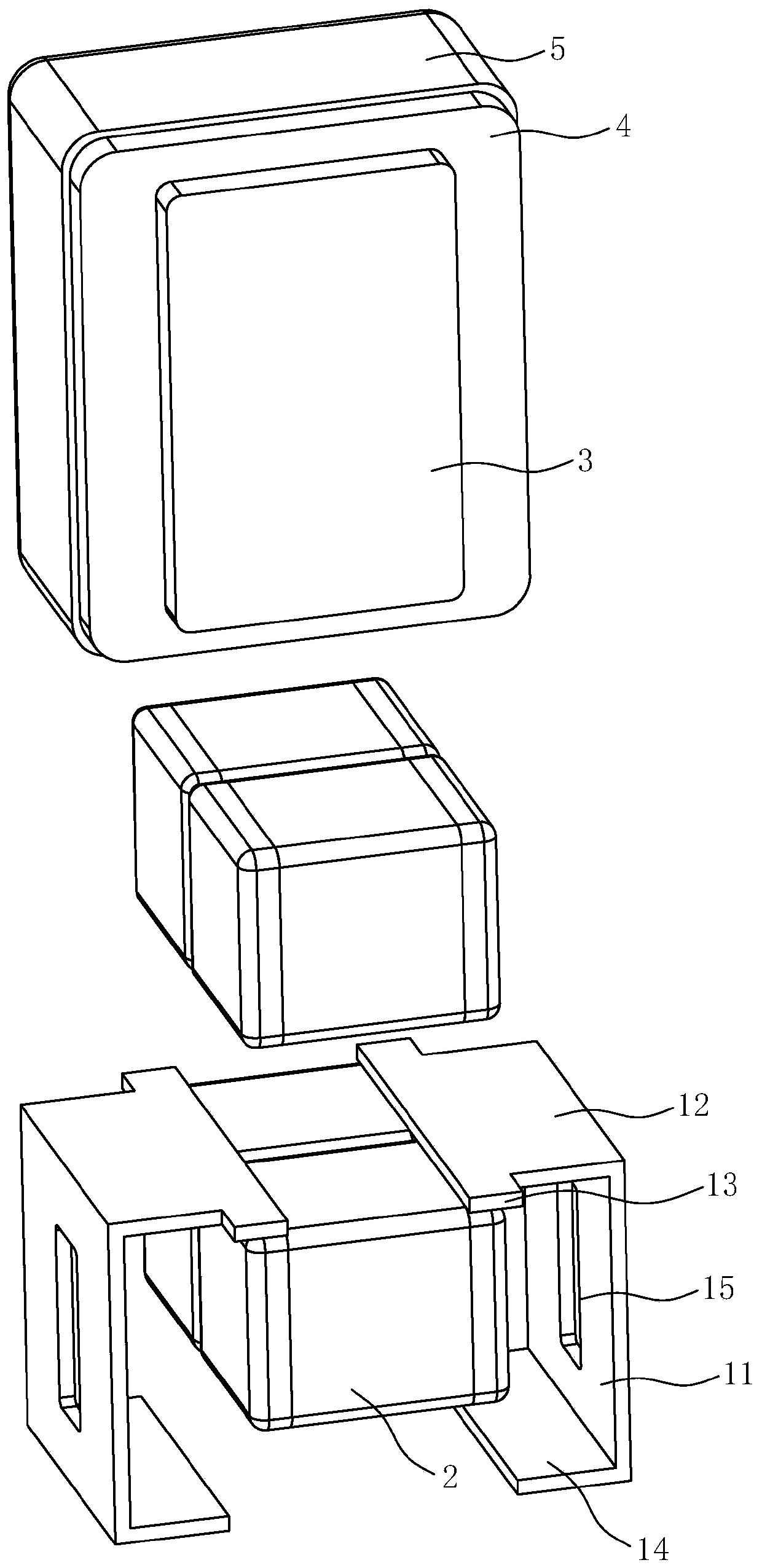

[0028] Such as figure 1 and figure 2 As shown, the soft multi-core group ceramic capacitor includes a frame, four ceramic capacitor chips 2 welded on the frame, an insulating layer 3 coated on the surface of the capacitor chip, an encapsulation layer 4 arranged on the surface of the insulating layer 3 and coated on the The protective layer 5 on the surface of the packaging adhesive layer 4, the frame has two pins 11 arranged at relative intervals, the pins 11 pass through the insulating layer 3, the packaging adhesive layer 4, and the protective layer 5 respectively, and the packaging adhesive layer 4 is semi-solidified , two ceramic capacitor chips 2 are respectively welded on the upper and lower sides of the frame.

[0029] The frame also includes two chip pads respectively arranged on the upper ends of the two pins 11 and arranged relatively horizontally, two-pin pads 14 respectively arranged on the lower ends of the two pins 11 and arranged relatively horizontally, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com