Friction nanogenerator with lubricant

A nano-generator and lubricant technology, applied in the direction of friction generators, synthetic resin layered products, chemical instruments and methods, etc., can solve problems such as poor power generation stability, decreased output performance, and reduced effective contact, and achieve The effect of reducing friction, reducing wear, and reducing loss of mechanical energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

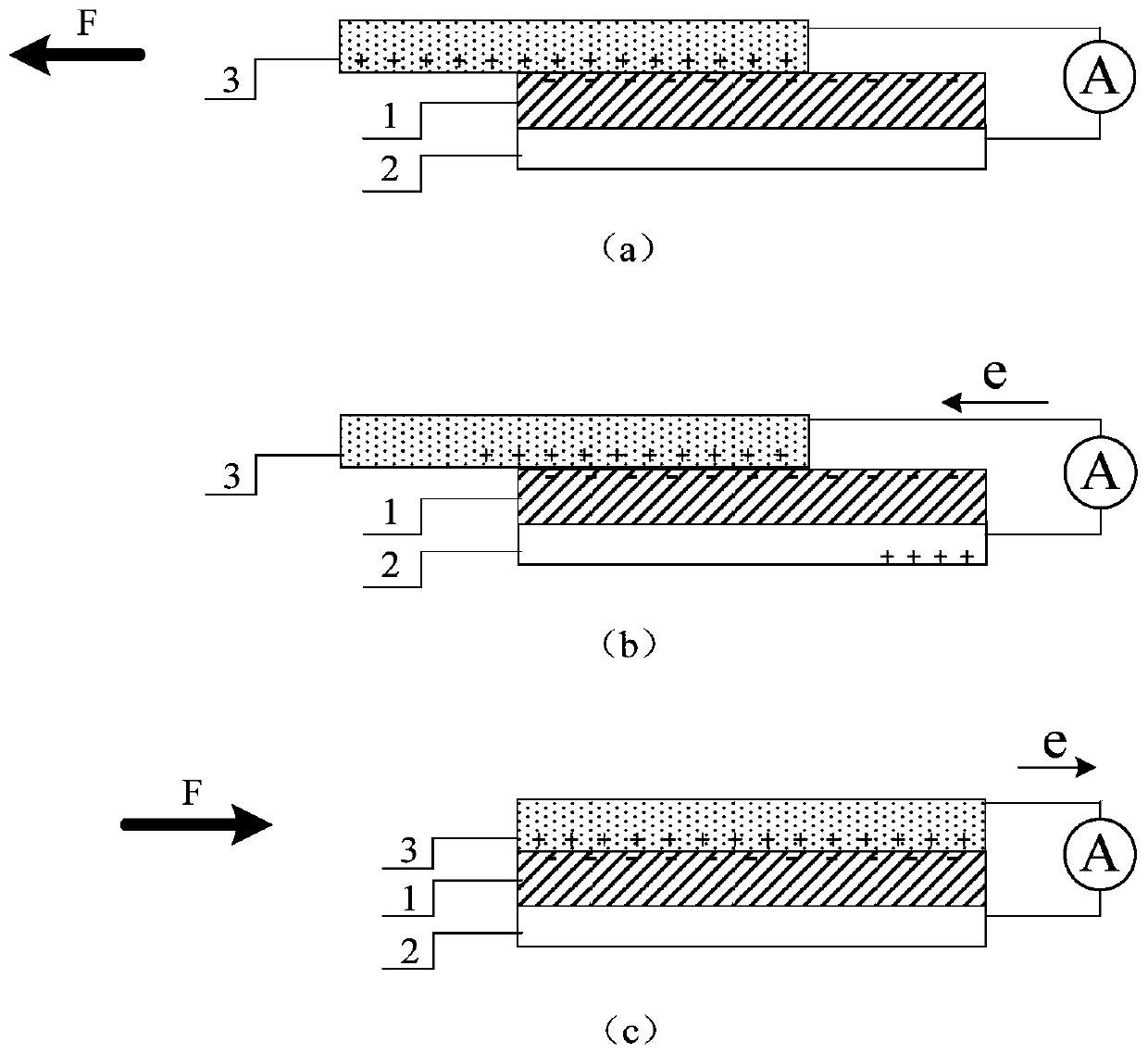

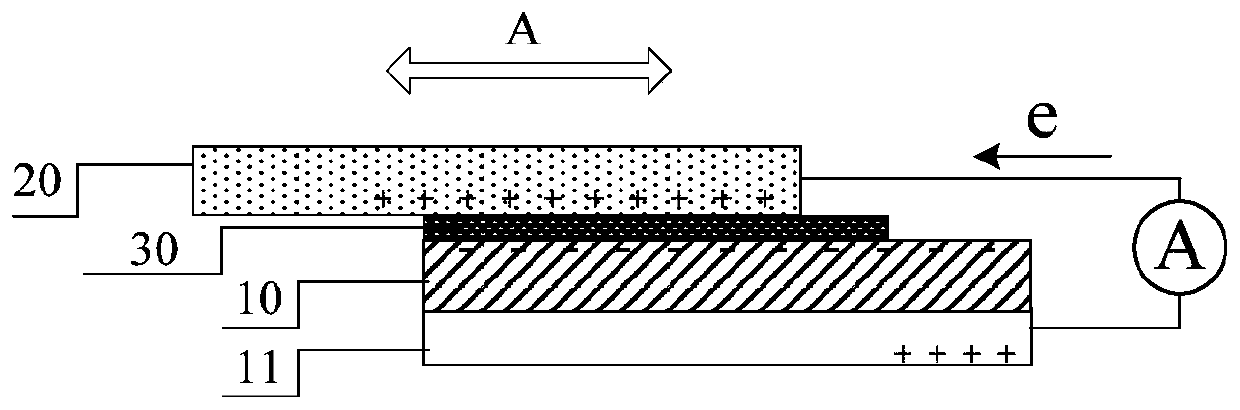

Method used

Image

Examples

Embodiment 1

[0047] The first friction layer 10 adopts a polyimide film (PI) with a thickness of 0.025 mm, and the second friction layer 20 adopts an aluminum foil with a thickness of 0.06 mm to obtain a friction nanogenerator (PI-Al for short) whose friction surface is PI-Al. ).

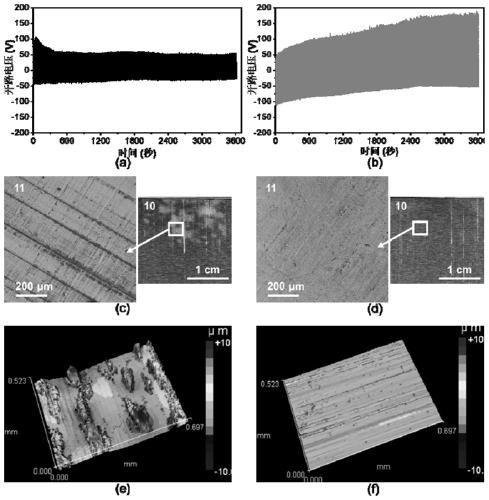

[0048] Squalane (liquid lubricant 30) was added dropwise to the surface of the first friction layer 10, the operation was carried out under the conditions of 10N and 1Hz for 1 hour, the open circuit voltage was collected, and the wear surface was analyzed. At the same time, the results under dry grinding conditions without any liquid lubricant were tested, and the results are as follows image 3 shown, using squalane as the liquid lubricant 30 ( image 3 Middle b) can significantly increase the output performance, while under dry grinding conditions ( image 3 Middle a), the open-circuit voltage output performance decreases gradually, and finally stabilizes at a lower value. From the observation of the wear s...

Embodiment 2

[0053] The first friction layer 10 adopts a polytetrafluoroethylene (PTFE) film with a thickness of 0.05 mm, and the second friction layer 20 adopts an aluminum foil with a thickness of 0.06 mm to obtain a friction nanogenerator (PTFE-Al for short) whose friction surface is PTFE-Al. ). The same liquid lubricant squalane and test conditions as in Example 1 were used. The results show that this technical solution is also applicable to PTFE-Al, under liquid lubrication, the output performance is improved and the wear is greatly reduced. Under dry grinding conditions, there is severe wear and a drop in output performance.

Embodiment 3

[0055] For triboelectric nanogenerators containing liquid lubrication, the properties of the liquid are the key to affecting the output performance of the generator. The present invention proposes important indicators for liquid selection: dielectric constant and viscosity of the liquid lubricant after researching and summarizing the output performance of a series of lubricating liquids. It is proposed that the use of low dielectric constant and low viscosity liquid lubricants can effectively guarantee or improve the output performance.

[0056] Comparison of the output performance of the PI-Al generators in Example 1 under different liquid lubrication. The liquid used and its main properties - relative permittivity and dynamic viscosity (mPa·s, 25°C) are as follows. serial number correspondence Image 6 Type of liquid in , where 1 means dry grinding. 2-Squalane (relative dielectric constant 2.09, dynamic viscosity 31.123), 3-liquid paraffin or mineral oil (2.1, 43.47), 4-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com