Preparation of high-protein pasteurized drinking yogurt

A pasteurized, drinking-type technology, applied in the direction of milk preparations, applications, dairy products, etc., can solve the problems that it is difficult to meet the taste requirements of drinking-type yogurt, rough taste, poor shear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

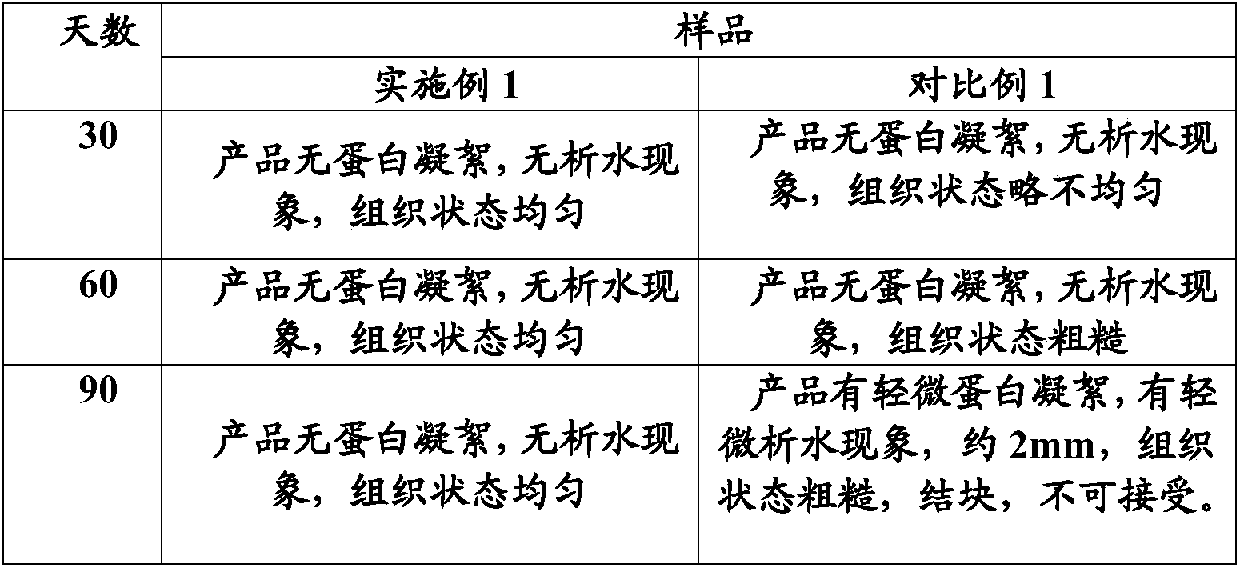

Examples

Embodiment 1

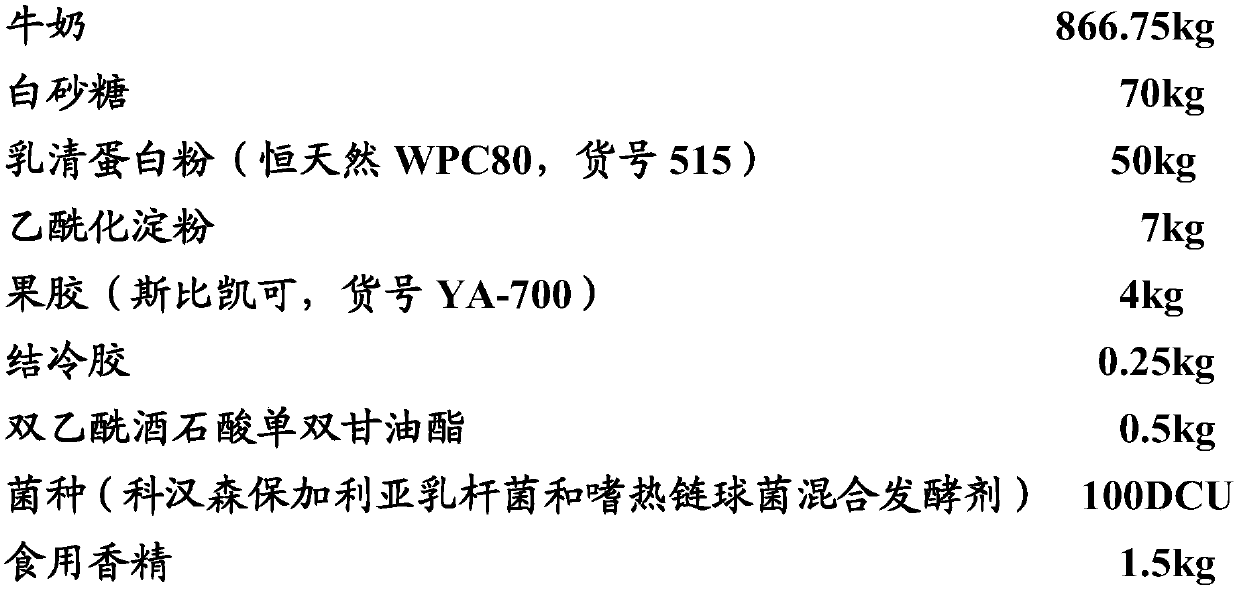

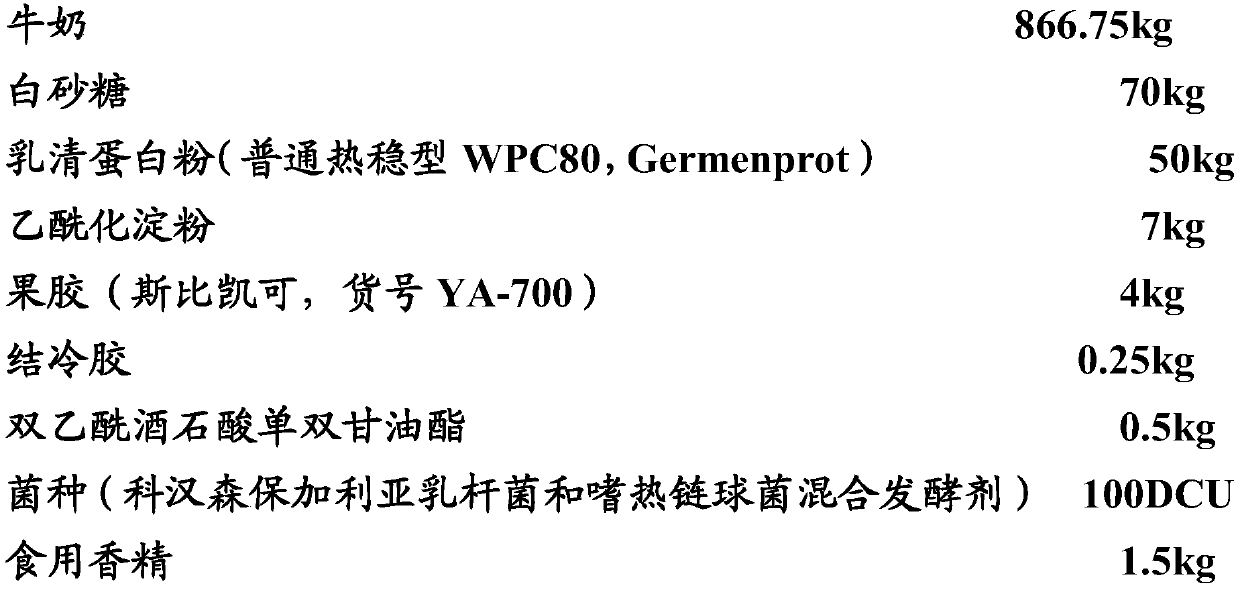

[0044] Product formula composition (contained in every 1000kg product)

[0045]

[0046] Process:

[0047] 1) Fermentation broth preparation: heat 50% of the total milk to 50-55°C, add white sugar, whey protein powder, modified starch, pectin, gellan gum, diacetyl tartaric acid mono-diglycerides into the milk , using equipment with mixing, dispersing, shearing, and emulsifying effects to make the material liquid into a uniform and dispersed mixture. The mixing time is kept at 15-20 minutes. After cooling, mix with the rest of the milk and add essence.

[0048] After mixing the solution is:

[0049] Degassing: temperature 60-65℃, pressure -0.4Mpa

[0050] Homogenization: Temperature 60-65℃, 30 / 150bar

[0051] Sterilization: sterilization temperature 95°C, sterilization time 300s

[0052] Fermentation: Insert strains, fermentation temperature 40-42°C, fermentation time 9h

[0053] 2) Homogenization, sterilization and filling:

[0054] Homogenize, sterilize and fill the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com