Preparation method of H2SO4 modified granular anthracite, H2SO4 modified granular anthracite and application

A technology of H2SO4 and anthracite, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problem of high cost, achieve fast adsorption rate, low cost, and increase the effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention H 2 SO 4 The preparation method of modified granular anthracite is as follows:

[0043] (1) Granular anthracite purification: the granular anthracite with a particle size of 0.8-1.2 mm is washed with deionized water, filtered, and dried for later use;

[0044] (2) Prepare H with a concentration of 0.5-6mol / L 2 SO 4 solution;

[0045] (3) Take the prepared H 2 SO 4 The solution is placed in a container, and the purified granular anthracite is added according to the solid-to-liquid ratio of 1:3-1:10;

[0046] (4) Take out the container after reacting in a water bath at 50-80°C for 1-4h, treat it under 40kHz room temperature ultrasonic conditions for 10min-90min, and then place it in a constant temperature shaker for 10-24h;

[0047] (5) the granular anthracite processed in step (4) is cleaned to neutrality with deionized water, and put into an oven to dry, that is, H 2 SO 4 Modified granular anthracite.

Embodiment 1H2

[0048] Example 1H 2 SO 4 Study on Adsorption Removal Efficiency of Modified Granular Anthracite

[0049] figure 1 It is a picture of the appearance of granular anthracite coal with a particle size of 0.8-1.2mm.

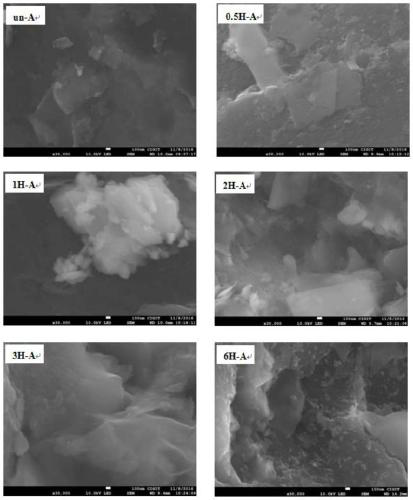

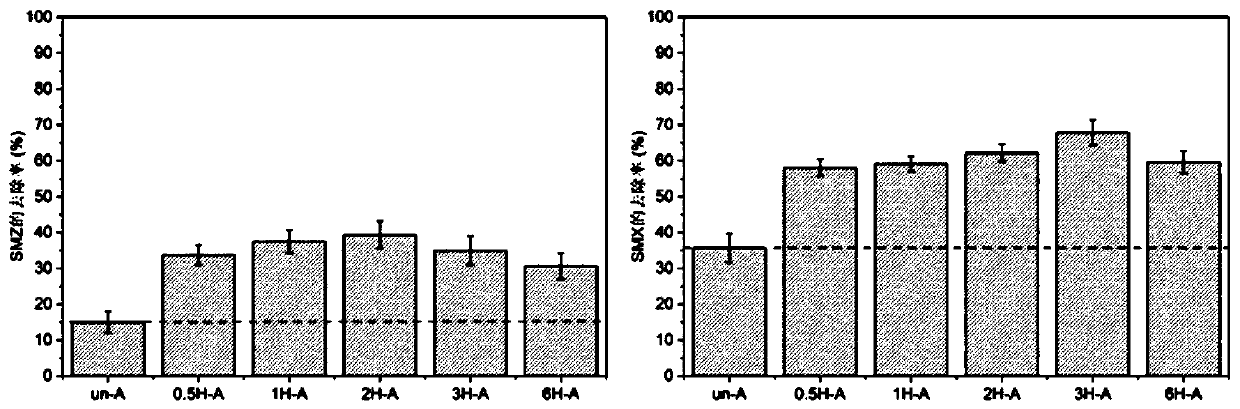

[0050] The 0.8-1.2mm granular anthracite filter material is washed with deionized water, filtered, and dried at 100°C for later use. Prepare 0.5mol / L, 1mol / L, 2mol / L, 3mol / L and 6mol / L H 2 SO 4 100ml of the solution were placed in conical flasks with stoppers, and 20g of dried anthracite particles were added respectively. Put the above-mentioned Erlenmeyer flask with stopper into a 70°C water bath, take it out after 2h of reaction, and after ultrasonic treatment at room temperature for 0.5h, put it into a shaker for 24h evenly, wash the anthracite with deionized water until neutral, and put it in 100°C Oven drying, that is, the corresponding concentration of H 2 SO 4 Solution-modified granular anthracite, labeled as 0.5H-anthracite (0.5H-A), 1H-anthracite (1H-...

Embodiment 2H2

[0054] Example 2H 2 SO 4 Adsorption Equilibrium Experiment of Modified Granular Anthracite

[0055] According to the method in embodiment 1, prepare the H of 3mol / L concentration 2 SO 4 Solution, modified particles of anthracite, prepared 3H-anthracite (3H-A).

[0056] Add 200 ml of SMZ or SMX solutions with different initial concentrations (50 μg / L, 100 μg / L, 200 μg / L, 500 μg / L, 1000 μg / L, 2000 μg / L, 5000 μg / L) into a series of 250 mL stoppered Erlenmeyer flasks. Add 100mg of granular anthracite or 3H-anthracite to the bottle, and place it in a constant temperature oscillator at (25±0.2)°C and 120rpm for 24h. Immediately after taking out the sample, filter it with a 0.45 μm glass fiber membrane, extract it with a SPE solid phase extraction device, and use a high performance liquid chromatography to measure the content of SMZ or SMX in the water sample of the filtered extract, and then calculate the adsorption of SMZ or SMX amount, such as Figure 4 .

[0057] Depend on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Equilibrium adsorption | aaaaa | aaaaa |

| Equilibrium adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com