Hybrid drive systems and vehicles

A drive system and hybrid technology, applied in hybrid vehicles, motor vehicles, power plants, etc., can solve the problems of shifting shock and frustration, and achieve the effect of alleviating the shock feeling, simple and compact structure, and improving the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

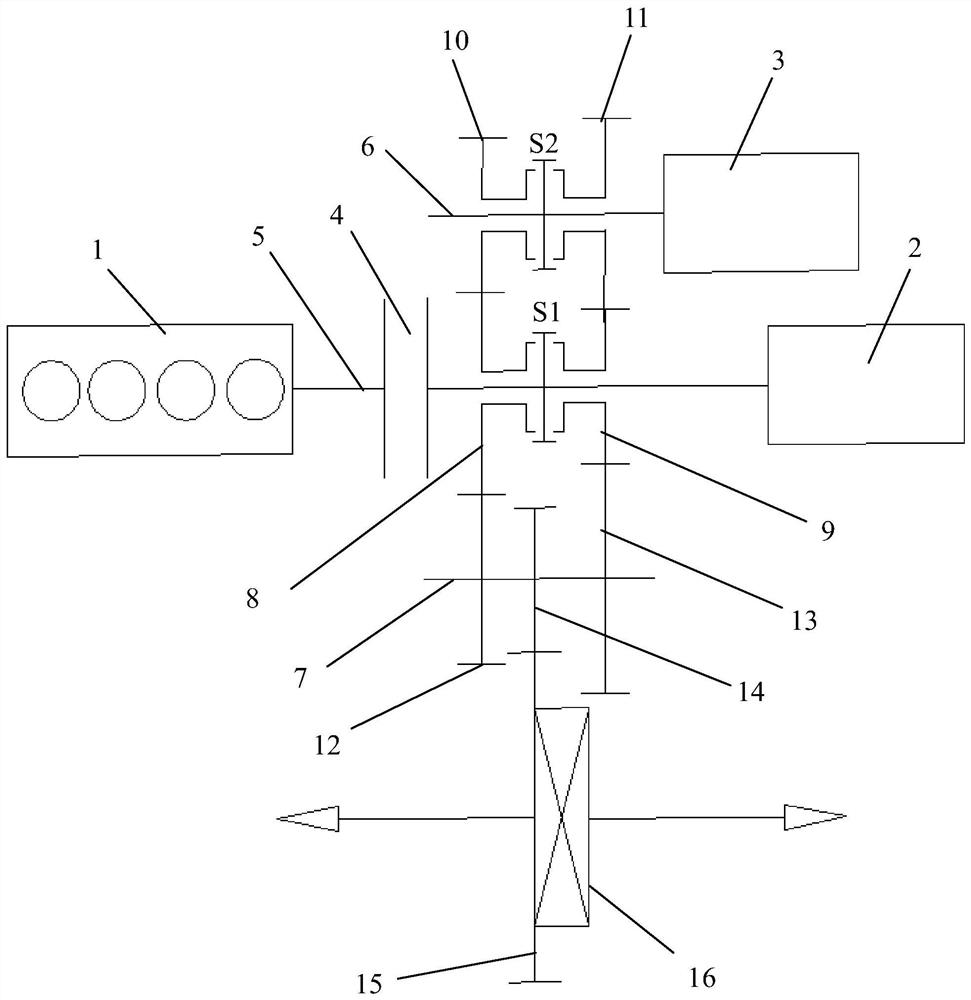

[0077] like figure 1 As shown, the hybrid drive system provided by the first embodiment of the present invention includes an engine 1, a first motor 2, a second motor 3, a connection and disconnection unit 4 and a transmission. The first motor 2 is the same as the engine 1. Shaft arrangement, the second electric machine 3 is arranged side by side with the engine 1 . The restriction on the mating surface of the second motor 3 and the engine 1 is eliminated, and the outer diameter of the second motor 3 can be increased. Since the first motor 2 and the engine 1 are arranged coaxially, the structure of the side surface can be reduced, and the mountability can be improved.

[0078] The transmission includes a first shaft 5 , a second shaft 6 , a third shaft 7 , a first synchronizer S1 , a second synchronizer S2 , a first motor first gear drive gear 8 , and a first motor second gear drive. Gear 9, second motor first gear driving gear 10, second motor second gear driving gear 11, f...

no. 2 example

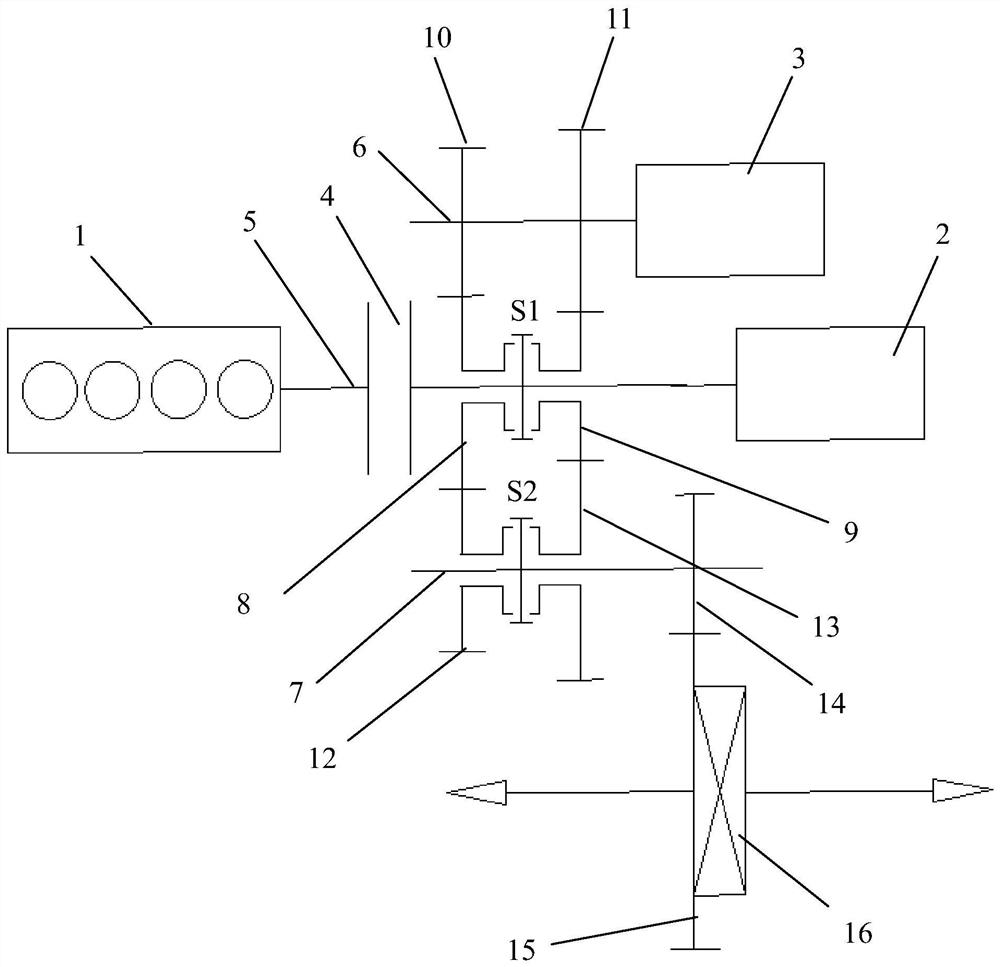

[0135] like figure 2 As shown, the hybrid drive system provided by the second embodiment of the present invention includes an engine 1, a first motor 2, a second motor 3, a connection and disconnection unit 4 and a transmission. The first motor 2 is the same as the engine 1. Shaft arrangement, the second electric machine 3 is arranged side by side with the engine 1 . The restriction on the mating surface of the second motor 3 and the engine 1 is eliminated, and the outer diameter of the second motor 3 can be increased. Since the first motor 2 and the engine 1 are arranged coaxially, the structure of the side surface can be reduced, and the mountability can be improved.

[0136] The transmission includes a first shaft 5 , a second shaft 6 , a third shaft 7 , a first synchronizer S1 , a second synchronizer S2 , a first motor first gear drive gear 8 , and a first motor second gear drive. Gear 9, second motor first gear driving gear 10, second motor second gear driving gear 11,...

no. 3 example

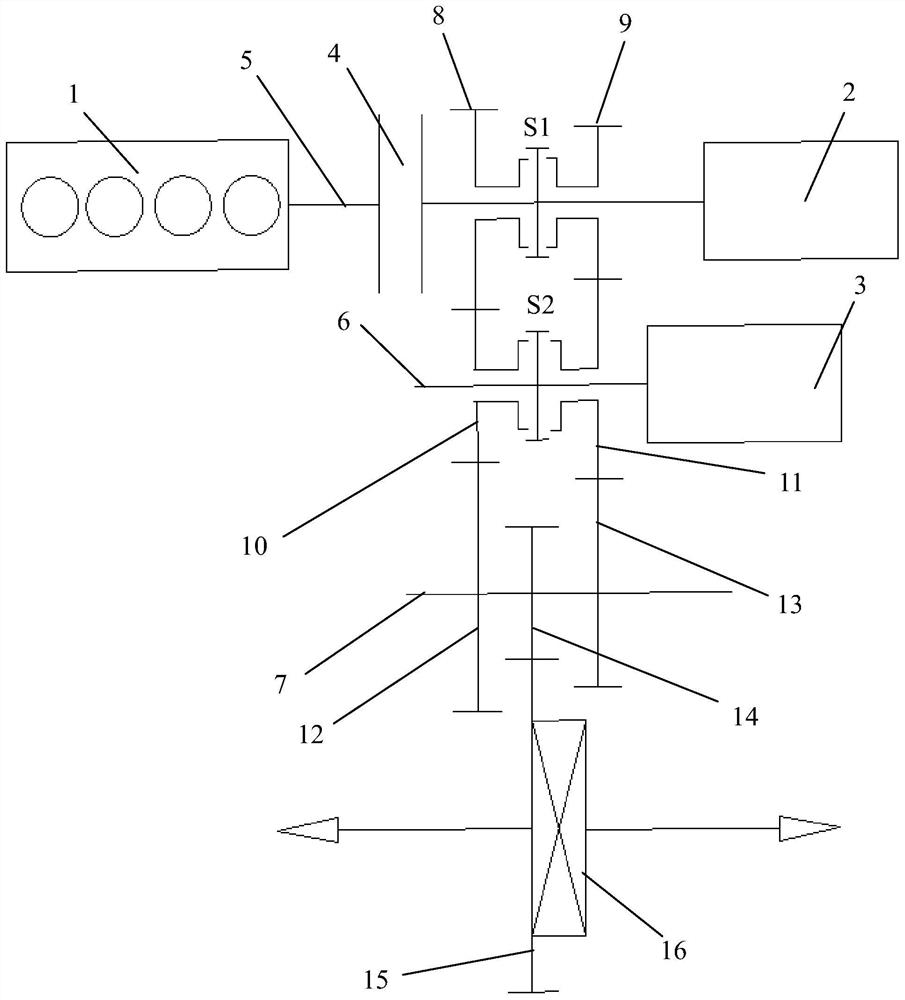

[0146] like image 3 As shown, the hybrid drive system provided by the third embodiment of the present invention includes an engine 1, a first motor 2, a second motor 3, a connection and disconnection unit 4 and a transmission. The first motor 2 is the same as the engine 1. Shaft arrangement, the second electric machine 3 is arranged side by side with the engine 1 . The restriction on the mating surface of the second motor 3 and the engine 1 is eliminated, and the outer diameter of the second motor 3 can be increased. Since the first motor 2 and the engine 1 are arranged coaxially, the structure of the side surface can be reduced, and the mountability can be improved.

[0147] The transmission includes a first shaft 5 , a second shaft 6 , a third shaft 7 , a first synchronizer S1 , a second synchronizer S2 , a first motor first gear drive gear 8 , and a first motor second gear drive. Gear 9, second motor first gear driving gear 10, second motor second gear driving gear 11, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com