Automobile lamp decoration ring sputtering aluminum plating system and process

A technology of sputtering coating and lighting decoration, which is applied in the field of sputtering coating to achieve the effect of reducing the possibility of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

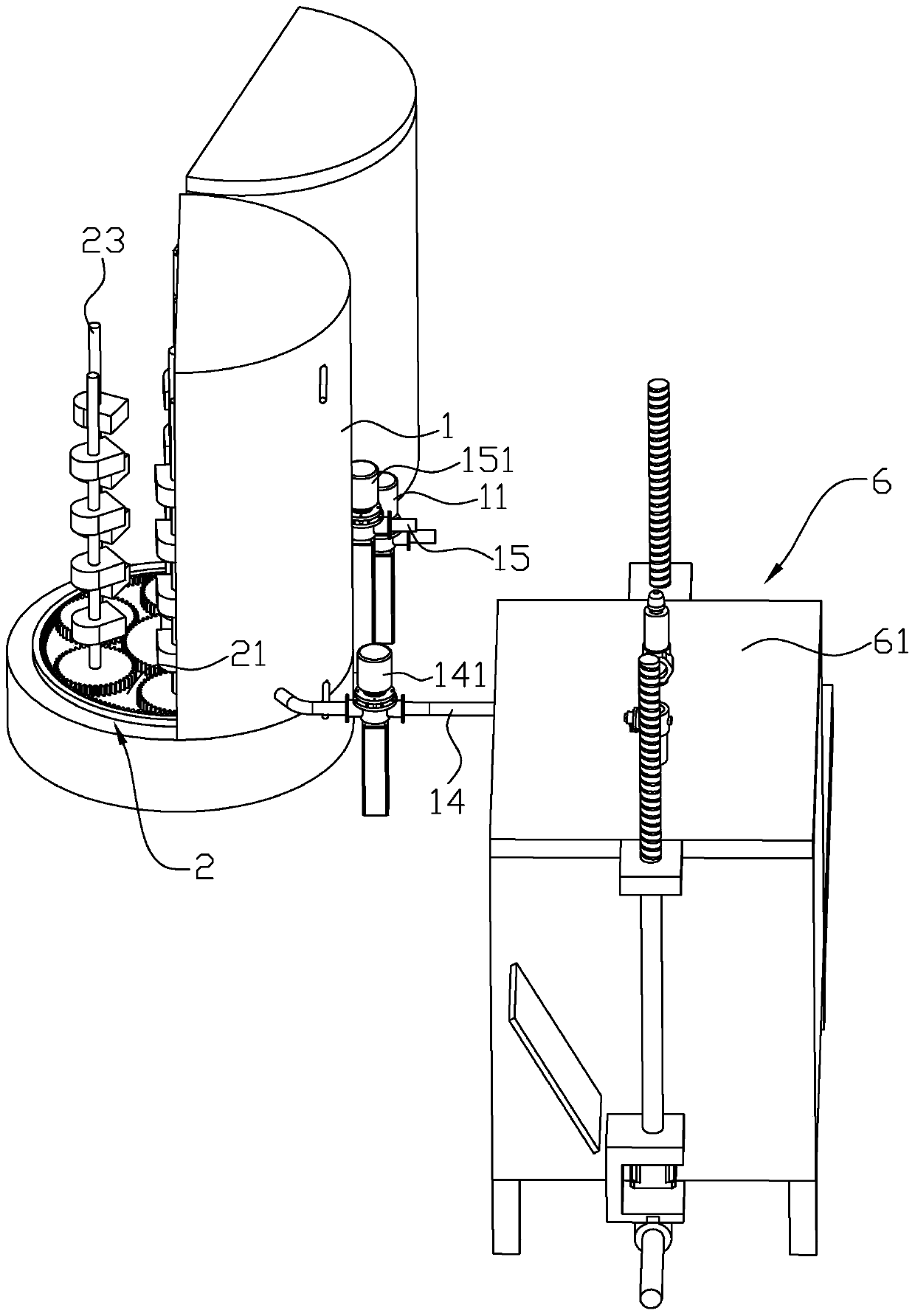

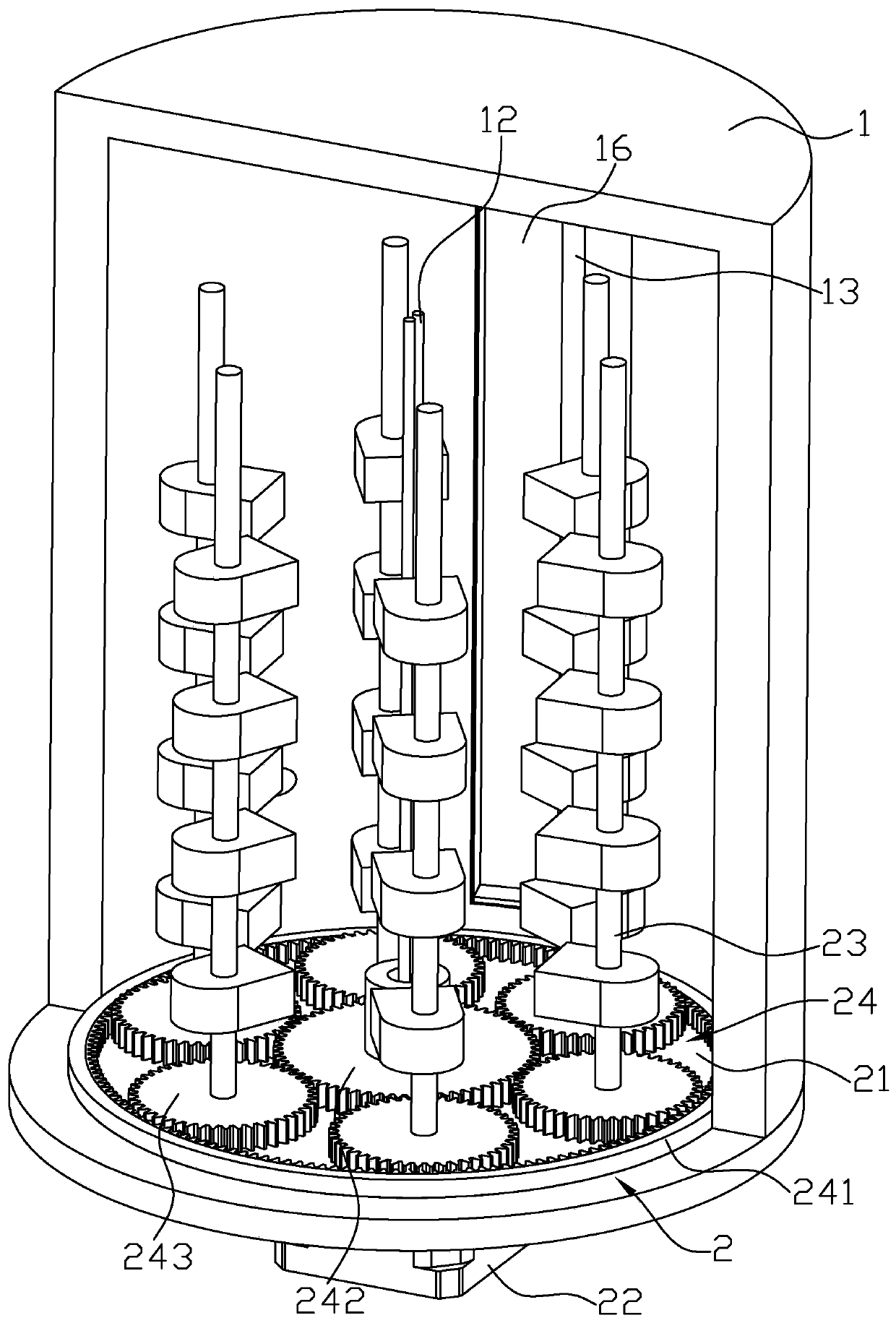

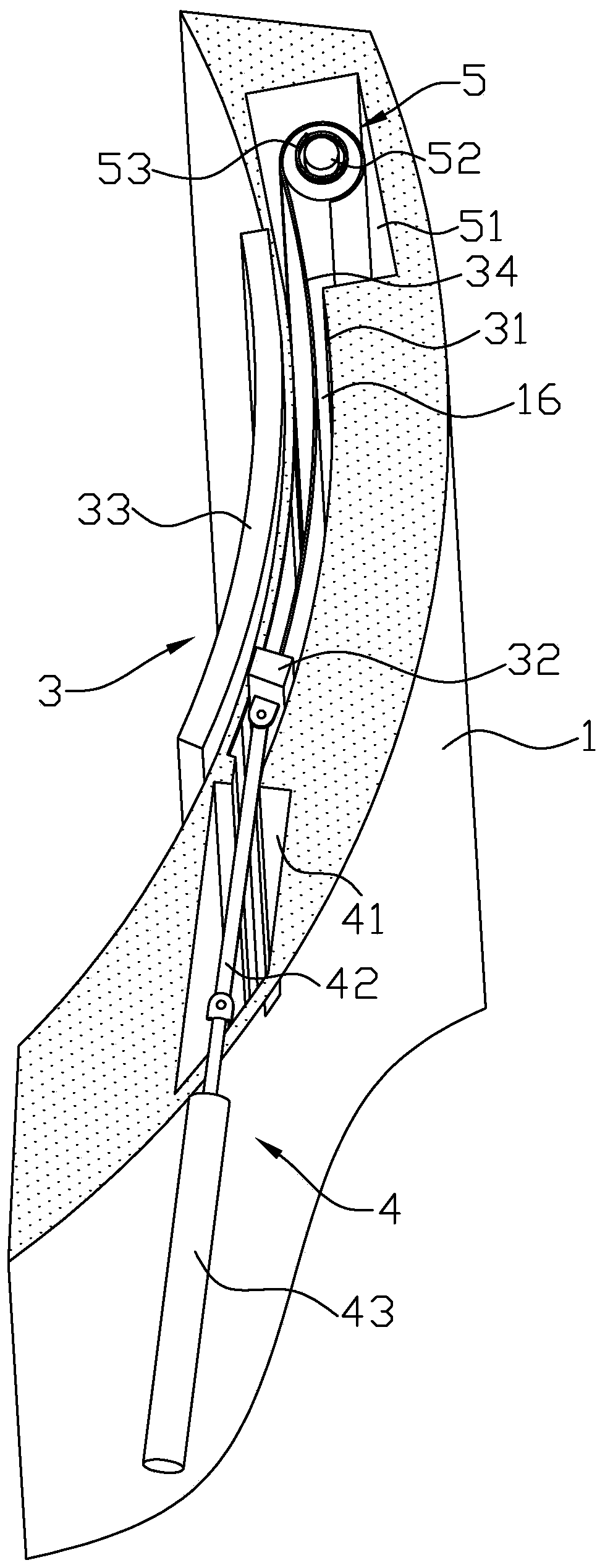

[0039] A car lamp bezel sputtering aluminum coating system, such as figure 1 and figure 2 As shown, it includes a vacuum chamber 1 and a vacuum pump 11. An aluminum rod 12 is vertically installed in the vacuum chamber 1, and an aluminum target 13 is installed in the side wall of the vacuum chamber 1. The aluminum rod 12 and the aluminum target 13 need to be connected to electricity. Therefore, the connection between the aluminum rod 12 and the aluminum target 13 and the side wall of the vacuum chamber 1 will be insulated. image 3 , the side wall of the vacuum chamber 1 is equipped with a shielding device 3 for shielding the aluminum target 13; one side of the vacuum chamber 1 is connected with a feed pipe 14 for conveying silicone oil, and the feed pipe 14 can be made by insulating cotton Insulation treatment, a silicone oil electric valve 141 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com